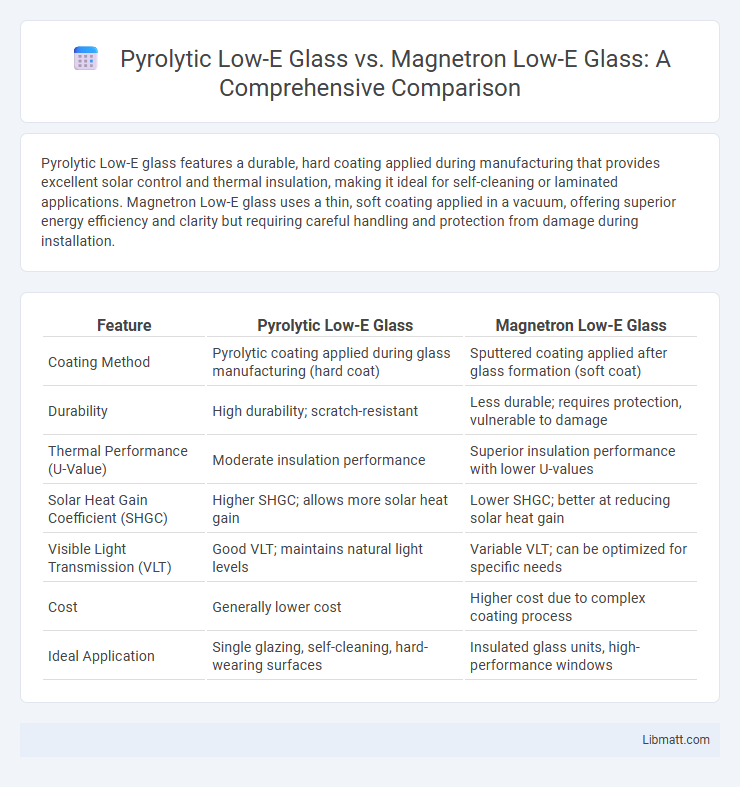

Pyrolytic Low-E glass features a durable, hard coating applied during manufacturing that provides excellent solar control and thermal insulation, making it ideal for self-cleaning or laminated applications. Magnetron Low-E glass uses a thin, soft coating applied in a vacuum, offering superior energy efficiency and clarity but requiring careful handling and protection from damage during installation.

Table of Comparison

| Feature | Pyrolytic Low-E Glass | Magnetron Low-E Glass |

|---|---|---|

| Coating Method | Pyrolytic coating applied during glass manufacturing (hard coat) | Sputtered coating applied after glass formation (soft coat) |

| Durability | High durability; scratch-resistant | Less durable; requires protection, vulnerable to damage |

| Thermal Performance (U-Value) | Moderate insulation performance | Superior insulation performance with lower U-values |

| Solar Heat Gain Coefficient (SHGC) | Higher SHGC; allows more solar heat gain | Lower SHGC; better at reducing solar heat gain |

| Visible Light Transmission (VLT) | Good VLT; maintains natural light levels | Variable VLT; can be optimized for specific needs |

| Cost | Generally lower cost | Higher cost due to complex coating process |

| Ideal Application | Single glazing, self-cleaning, hard-wearing surfaces | Insulated glass units, high-performance windows |

Introduction to Low-E Glass Technologies

Pyrolytic Low-E glass features a durable, hard coating applied during the glass manufacturing process, enhancing solar control and thermal insulation by reflecting infrared heat while allowing visible light transmission. Magnetron Low-E glass uses a thin, soft metallic coating deposited in a vacuum chamber, offering superior thermal performance and reduced emissivity but requiring careful handling due to its delicate surface. Both technologies improve energy efficiency in windows by minimizing heat transfer and optimizing indoor temperature regulation in residential and commercial applications.

What is Pyrolytic Low-E Glass?

Pyrolytic Low-E glass features a durable, hard coating applied during the glass manufacturing process through chemical vapor deposition, which enhances thermal insulation by reflecting infrared energy while allowing visible light to pass. This type of glass is often used in single-pane applications and offers improved energy efficiency by reducing heat transfer and minimizing UV damage to interiors. Your choice of Pyrolytic Low-E glass can significantly influence energy savings and comfort, especially in regions with varying temperatures.

What is Magnetron Low-E Glass?

Magnetron Low-E glass features a thin, transparent metallic coating applied through magnetron sputtering, enhancing solar control and thermal insulation. Compared to Pyrolytic Low-E glass, magnetron Low-E glass offers superior energy efficiency with lower emissivity and better visible light transmittance. It is commonly used in high-performance windows and facades for reduced heat loss and improved indoor comfort.

Manufacturing Processes Compared

Pyrolytic Low-E glass undergoes a chemical vapor deposition process in which a thin, durable metallic oxide coating is applied at high temperatures during the float glass manufacturing, resulting in a hard, scratch-resistant surface. Magnetron Low-E glass is produced using a physical vapor deposition technique in a vacuum chamber where multiple layers of metal are sputtered onto already formed glass, creating a softer, more delicate coating that often requires insulating glazing units for protection. The differences in manufacturing affect coating durability, cost, and performance, with pyrolytic coatings being more robust for single-pane applications and magnetron coatings offering superior emissivity control in double or triple glazing.

Performance and Energy Efficiency

Pyrolytic Low-E glass features a durable, hard coating applied during the manufacturing process, offering excellent thermal insulation and durability for your windows. Magnetron Low-E glass uses a thin metallic coating applied in a vacuum, providing superior energy efficiency by reflecting heat while allowing natural light to enter. Your choice impacts energy savings significantly, as magnetron coatings typically provide higher solar control and better performance in extreme climates.

Durability and Longevity

Pyrolytic Low-E glass, also known as hard-coat Low-E, is characterized by a durable, abrasion-resistant coating fused during the glass manufacturing process, ensuring enhanced longevity even in exposed environmental conditions. In contrast, magnetron Low-E glass features a softer, sputtered coating applied post-production, which may be more susceptible to degradation and damage if not properly protected by sealed units. The inherent hardness of pyrolytic coatings often results in better scratch resistance and long-term performance in window applications compared to the relatively delicate sputtered coatings of magnetron Low-E glass.

Visual Clarity and Aesthetic Differences

Pyrolytic Low-E glass offers superior visual clarity with a naturally smooth, durable coating that is less likely to cause haziness or discoloration, making it ideal for maintaining aesthetic appeal in high-visibility applications. In comparison, magnetron sputtered Low-E glass features multiple layers that can sometimes produce slight reflectivity or a tinted appearance, subtly affecting the overall transparency and color fidelity. Your choice between these technologies will depend on the desired balance between consistent clarity and advanced energy performance.

Ideal Applications for Each Glass Type

Pyrolytic Low-E glass is ideal for applications requiring durability and cost-effectiveness, such as single-pane windows and storm doors, where it can withstand environmental exposure during manufacturing and installation. Magnetron Low-E glass excels in insulating glass units for residential and commercial windows, offering superior thermal performance by reducing heat transfer and improving energy efficiency. Both glass types enhance building comfort but differ in suitability based on installation methods and performance needs.

Cost Comparison and Value Proposition

Pyrolytic Low-E glass generally costs more upfront due to its durable hard coat, but offers long-term savings through enhanced energy efficiency and scratch resistance ideal for window manufacturing. Magnetron Low-E glass, produced via sputter coating, typically has a lower initial price but may require more maintenance and careful handling to preserve its soft coating benefits, translating to potentially higher long-term costs. The value proposition favors pyrolytic coatings in applications demanding durability and ease of fabrication, while magnetron Low-E glass provides cost-effective performance suitable for controlled environments with lower exposure risks.

Choosing the Right Low-E Glass for Your Project

Pyrolytic Low-E glass features a durable, hard coating applied during the manufacturing process, making it ideal for projects requiring easy handling and on-site fabrication without damaging the coating. Magnetron Low-E glass, or sputter-coated glass, offers superior thermal insulation and solar control properties, often preferred for high-performance commercial buildings where maximum energy efficiency is crucial. Selecting between Pyrolytic and Magnetron Low-E glass depends on project needs such as durability, thermal performance, installation methods, and budget constraints to optimize energy savings and longevity.

Pyrolytic Low-E glass vs magnetron Low-E glass Infographic

libmatt.com

libmatt.com