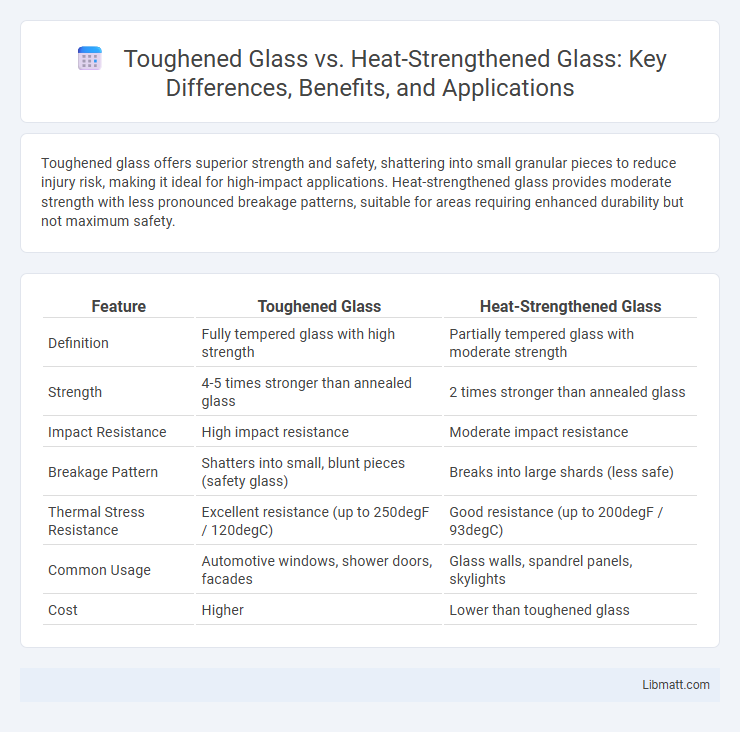

Toughened glass offers superior strength and safety, shattering into small granular pieces to reduce injury risk, making it ideal for high-impact applications. Heat-strengthened glass provides moderate strength with less pronounced breakage patterns, suitable for areas requiring enhanced durability but not maximum safety.

Table of Comparison

| Feature | Toughened Glass | Heat-Strengthened Glass |

|---|---|---|

| Definition | Fully tempered glass with high strength | Partially tempered glass with moderate strength |

| Strength | 4-5 times stronger than annealed glass | 2 times stronger than annealed glass |

| Impact Resistance | High impact resistance | Moderate impact resistance |

| Breakage Pattern | Shatters into small, blunt pieces (safety glass) | Breaks into large shards (less safe) |

| Thermal Stress Resistance | Excellent resistance (up to 250degF / 120degC) | Good resistance (up to 200degF / 93degC) |

| Common Usage | Automotive windows, shower doors, facades | Glass walls, spandrel panels, skylights |

| Cost | Higher | Lower than toughened glass |

Overview of Toughened and Heat-Strengthened Glass

Toughened glass, also known as tempered glass, undergoes rapid cooling after heating to increase its strength, making it approximately four times stronger than annealed glass and shattering into small, blunt pieces upon breakage for safety. Heat-strengthened glass is heated and cooled at a slower rate, resulting in a product that is about twice as strong as annealed glass while maintaining higher resistance to thermal stress but breaking into larger, less safe shards. Both types are widely used in architectural and automotive applications, with toughened glass preferred for safety-critical installations and heat-strengthened glass chosen for its balance of strength and thermal performance.

How Each Type of Glass is Manufactured

Toughened glass is produced by heating annealed glass to approximately 620degC followed by rapid quenching with high-pressure air, creating compressive stresses on the surface and tensile stresses in the core. Heat-strengthened glass undergoes a similar heating process but is cooled more slowly, which results in lower surface compressive stress compared to toughened glass. This controlled cooling process gives heat-strengthened glass improved strength over annealed glass while maintaining better resistance to thermal stress than toughened glass.

Key Differences in Strength and Durability

Toughened glass, also known as tempered glass, undergoes rapid cooling during manufacturing, resulting in a compressive stress layer that makes it approximately four to five times stronger than standard glass. Heat-strengthened glass experiences slower cooling, providing about twice the strength of annealed glass but less than toughened glass, making it a middle ground in both durability and resistance to thermal stress. Your choice between the two should consider the required strength for impact resistance and the specific application environment where thermal performance and safety are critical.

Visual Appearance and Surface Quality

Toughened glass features a uniform surface with minimal distortion due to rapid cooling during manufacture, resulting in a clear and smooth visual appearance ideal for architectural applications. Heat-strengthened glass exhibits slight surface waviness and minor optical distortions caused by slower cooling rates, which may affect visual clarity compared to toughened glass. The superior surface quality of toughened glass makes it preferable for installations where aesthetic precision and minimal visual impairment are critical.

Breakage Patterns: What Happens Under Stress

Toughened glass shatters into small, blunt granules upon breakage, minimizing injury risks, while heat-strengthened glass breaks into larger, more jagged shards that pose greater harm. Both types undergo thermal or chemical treatments to enhance strength, but toughened glass withstands higher stress levels before failure. In applications demanding safety and impact resistance, toughened glass offers superior performance due to its controlled fragmentation pattern under stress.

Common Applications for Toughened Glass

Toughened glass is widely used in applications requiring high safety and durability, such as vehicle windows, shower doors, facades, and glass railings. Its ability to shatter into small, blunt pieces reduces injury risk, making it ideal for architectural glazing and automotive industries. Your choices for safety-critical projects often favor toughened glass due to its superior strength and impact resistance.

Typical Uses of Heat-Strengthened Glass

Heat-strengthened glass is commonly used in applications requiring moderate strength and thermal resistance, such as facades, skylights, and spandrel glass in curtain wall systems. It offers improved durability over annealed glass, making it suitable for insulated glass units and window panes where impact resistance is beneficial but full tempering is unnecessary. These typical uses balance cost-effectiveness with enhanced performance in commercial and residential buildings.

Safety Standards and Building Codes

Toughened glass meets stringent safety standards such as ASTM C1048 and EN 12150, making it suitable for applications requiring high impact resistance and shatter-proof performance in compliance with international building codes. Heat-strengthened glass, complying with standards like ASTM C1048 but with lower impact resistance, is often used where moderate strength and thermal stress resistance are needed without the mandatory safety glazing requirements. Building codes in areas prone to seismic activity or high wind loads typically mandate toughened glass due to its enhanced breakage behavior and safety features compared to heat-strengthened glass.

Cost Comparison: Toughened vs Heat-Strengthened Glass

Toughened glass typically costs 20-40% more than heat-strengthened glass due to its higher strength and safety performance. Heat-strengthened glass offers a more affordable option while providing moderate strength suitable for many architectural applications. Your choice depends on balancing budget constraints with the required durability and safety standards for the project.

Choosing the Right Glass for Your Project

Toughened glass offers maximum strength and safety by shattering into small, rounded pieces, making it ideal for high-impact areas like doors and windows in commercial buildings. Heat-strengthened glass provides moderate strength, resisting thermal stress and reducing the risk of breakage in environments with temperature fluctuations, suitable for facade glazing and skylights. Understanding the specific requirements of your project, such as safety standards and thermal resistance, ensures you select the most effective glass type for durability and performance.

Toughened glass vs heat-strengthened glass Infographic

libmatt.com

libmatt.com