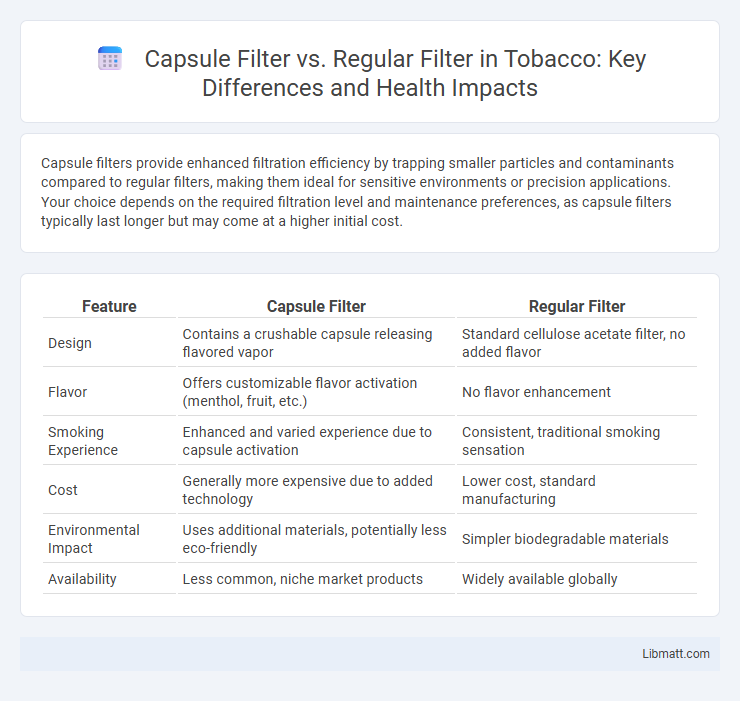

Capsule filters provide enhanced filtration efficiency by trapping smaller particles and contaminants compared to regular filters, making them ideal for sensitive environments or precision applications. Your choice depends on the required filtration level and maintenance preferences, as capsule filters typically last longer but may come at a higher initial cost.

Table of Comparison

| Feature | Capsule Filter | Regular Filter |

|---|---|---|

| Design | Contains a crushable capsule releasing flavored vapor | Standard cellulose acetate filter, no added flavor |

| Flavor | Offers customizable flavor activation (menthol, fruit, etc.) | No flavor enhancement |

| Smoking Experience | Enhanced and varied experience due to capsule activation | Consistent, traditional smoking sensation |

| Cost | Generally more expensive due to added technology | Lower cost, standard manufacturing |

| Environmental Impact | Uses additional materials, potentially less eco-friendly | Simpler biodegradable materials |

| Availability | Less common, niche market products | Widely available globally |

Introduction to Capsule Filters and Regular Filters

Capsule filters use layers of capsules to preserve spatial hierarchies in data, offering improved feature detection compared to regular filters, which apply fixed kernels for pattern recognition. Regular filters excel in straightforward feature extraction for image processing tasks but often lose spatial relationships within the input. Your choice between these depends on the complexity of patterns and the need for preserving spatial information in your application.

Core Differences Between Capsule and Regular Filters

Capsule filters use a multi-layered design with pleated media enclosed in a plastic or metal capsule, providing higher filtration efficiency and longer service life compared to regular filters, which typically feature a flat or folded paper element. You'll find capsule filters excel in fine particle removal and durability under harsher conditions, while regular filters offer basic filtration suitable for less demanding environments. The core difference lies in the construction and performance, where capsule filters combine enhanced filtration capacity with structural reinforcement to ensure consistent and reliable air or fluid purity.

Filtration Mechanisms Explained

Capsule filters utilize a depth filtration mechanism, capturing contaminants within layers of microfibers, effectively trapping particles throughout the filter matrix for enhanced dirt-holding capacity. Regular filters typically rely on surface filtration, where particles accumulate on the exterior media, often resulting in faster clogging and reduced efficiency over time. The layered design of capsule filters provides superior filtration performance, extended service life, and consistent flow rates compared to conventional regular filters.

Material Composition and Design

Capsule filters are typically made from advanced synthetic fibers or composites designed to trap fine particles efficiently, featuring a pleated, cylindrical structure that maximizes surface area and airflow. Regular filters often use basic materials such as paper or foam with a flat or simple folded design, offering standard filtration suitable for less demanding environments. Your choice depends on the need for enhanced dust capacity and durability offered by capsule filters versus the cost-effectiveness and ease of replacement in regular filters.

Application and Industry Suitability

Capsule filters are ideal for pharmaceutical, biotech, and food industries where sterile, high-purity filtration of small batch volumes is critical. Regular filters suit large-scale industrial applications such as water treatment, HVAC systems, and chemical processing due to their durability and cost-effectiveness. Your choice depends on the specific filtration requirements, including cleanliness standards and production scale.

Ease of Installation and Maintenance

Capsule filters offer superior ease of installation due to their compact, self-contained design that minimizes the need for complex assembly and reduces downtime during replacement. Regular filters often require more extensive handling and cleaning, increasing maintenance time and labor costs. Choosing a capsule filter for your system can streamline maintenance processes, ensuring quicker filter changes and improved operational efficiency.

Filtration Efficiency and Performance

Capsule filters typically offer superior filtration efficiency compared to regular filters, often removing particles as small as 0.1 microns with a higher capture rate, making them ideal for critical environments like pharmaceuticals and biotech. Their unique design minimizes contamination risk and enhances performance consistency by maintaining low pressure drops even at high flow rates. Regular filters, while effective for general use, usually have lower efficiency ranges and can exhibit reduced performance due to clogging and less advanced material construction.

Cost-Effectiveness and Longevity

Capsule filters typically offer greater cost-effectiveness due to their longer lifespan and lower maintenance requirements compared to regular filters, reducing replacement frequency and downtime. Their advanced media design enhances filtration efficiency, which extends filter life and minimizes operational expenses over time. Regular filters may have lower initial costs but often lead to higher total expenses due to frequent replacements and decreased durability.

Safety, Compliance, and Sterilization

Capsule filters provide enhanced safety by reducing operator exposure to hazardous materials through fully enclosed designs, meeting stringent regulatory compliance such as FDA and EMA guidelines for sterile processing. Their single-use construction minimizes cross-contamination risks and ensures consistent sterilization via gamma irradiation or ethylene oxide methods. Regular filters often require manual handling and cleaning, increasing contamination potential and complicating adherence to aseptic processing standards.

Choosing the Right Filter for Your Needs

Capsule filters provide superior filtration efficiency and longer service life compared to regular filters, making them ideal for applications requiring high contaminant retention and minimal maintenance. Regular filters tend to be more cost-effective and easier to replace, suitable for less demanding environments or short-term use. Assessing your specific filtration requirements, such as particle size removal and system compatibility, helps you choose the most effective filter for your needs.

Capsule filter vs Regular filter Infographic

libmatt.com

libmatt.com