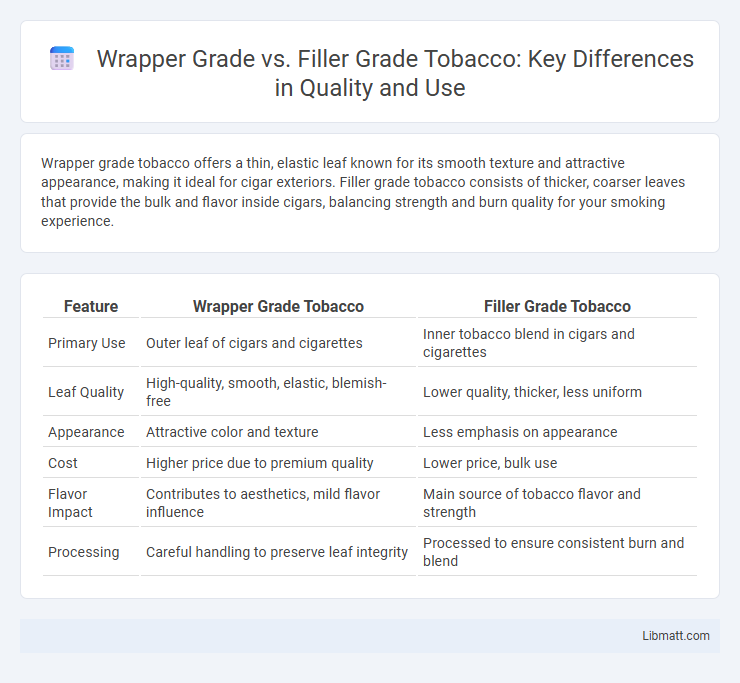

Wrapper grade tobacco offers a thin, elastic leaf known for its smooth texture and attractive appearance, making it ideal for cigar exteriors. Filler grade tobacco consists of thicker, coarser leaves that provide the bulk and flavor inside cigars, balancing strength and burn quality for your smoking experience.

Table of Comparison

| Feature | Wrapper Grade Tobacco | Filler Grade Tobacco |

|---|---|---|

| Primary Use | Outer leaf of cigars and cigarettes | Inner tobacco blend in cigars and cigarettes |

| Leaf Quality | High-quality, smooth, elastic, blemish-free | Lower quality, thicker, less uniform |

| Appearance | Attractive color and texture | Less emphasis on appearance |

| Cost | Higher price due to premium quality | Lower price, bulk use |

| Flavor Impact | Contributes to aesthetics, mild flavor influence | Main source of tobacco flavor and strength |

| Processing | Careful handling to preserve leaf integrity | Processed to ensure consistent burn and blend |

Understanding Wrapper Grade vs Filler Grade Tobacco

Wrapper grade tobacco is harvested from the outer leaves of the tobacco plant, prized for its elasticity, color, and smooth texture, making it perfect for enclosing cigars. Filler grade tobacco consists of the inner leaves, offering a robust flavor profile and body that enhances the cigar's overall smoking experience. The quality differentiation between wrapper and filler grades directly impacts the cigar's appearance, burn consistency, and taste complexity.

Key Characteristics of Wrapper Grade Tobacco

Wrapper grade tobacco is distinguished by its large, uniform leaves with smooth texture, few veins, and vibrant color that enhance the cigar's aesthetic appeal and burn quality. It features thinner leaves with higher elasticity and finer veins, providing excellent combustibility and burn control essential for an even wrapper. The chemical composition includes lower nicotine and higher sugar content, contributing to a smoother, more flavorful smoking experience.

Key Characteristics of Filler Grade Tobacco

Filler grade tobacco is characterized by its robust flavor, thicker cut, and higher nicotine content, making it ideal for the interior of cigars where slow burning and strong taste are essential. Unlike wrapper grade tobacco, which requires smoothness, elasticity, and flawless appearance for aesthetic appeal, filler grade tobacco emphasizes strength and burn quality to enhance the cigar's overall smoking experience. Your choice of filler grade tobacco directly influences the cigar's body, flavor complexity, and smoking duration.

Visual Differences: Wrapper vs Filler Tobacco

Wrapper grade tobacco features larger, more uniform leaves with smooth textures and vibrant colors, which contribute to the cigar's aesthetic appeal. Filler grade tobacco consists of smaller, less uniform leaves with varied textures and shades, providing the cigar's core flavor and structure. These visual distinctions are key quality indicators in cigar production and influence both appearance and smoking experience.

Flavor Impact: Wrapper Grade vs Filler Grade

Wrapper grade tobacco delivers a smoother and more refined flavor, often characterized by subtle sweetness and aromatic complexity that enhances the cigar's overall profile. Filler grade tobacco contributes robust, bold, and varied flavor notes, providing depth and strength to Your smoking experience. The balance between wrapper and filler grades shapes the cigar's flavor intensity and richness, making both essential for a well-rounded taste.

Cultivation and Processing Techniques

Wrapper grade tobacco requires meticulous cultivation with careful attention to soil quality, sun exposure, and curing methods to produce thin, elastic leaves with uniform color and minimal blemishes. Filler grade tobacco undergoes less rigorous selection and curing processes, focusing on bulk and flavor characteristics rather than visual perfection. Your choice between wrapper and filler tobaccos depends on the specific cultivation and processing techniques tailored to optimize leaf texture and combustion properties for different cigar components.

Quality Assessment: Wrapper vs Filler Tobacco

Wrapper tobacco undergoes stringent quality assessment focusing on factors like elasticity, color uniformity, and absence of blemishes, as it directly impacts the cigar's visual appeal and burn consistency. Filler tobacco quality assessment prioritizes flavor complexity, combustion properties, and moisture content to ensure a balanced and satisfying smoking experience. High-grade wrapper tobacco typically commands a premium due to its rarity and aesthetic importance, whereas filler grades are evaluated more on smoking characteristics and blend compatibility.

Pricing Differences in the Tobacco Market

Wrapper grade tobacco commands significantly higher prices in the tobacco market due to its superior quality, elasticity, and appearance, which are essential for premium cigar production. Filler grade tobacco, being less visually appealing and more abundant, is priced lower as it forms the inner core of cigars and influences flavor more than appearance. Market data consistently shows wrapper leaf prices exceeding filler leaf costs by up to three times, reflecting the critical role of wrapper quality in product valuation.

Wrapper and Filler Selection in Cigar Manufacturing

Wrapper and filler selection in cigar manufacturing involves distinct quality criteria, where wrapper grade tobacco must exhibit flawless appearance, elasticity, and consistent color to ensure a smooth, attractive finish. Filler grade tobacco emphasizes flavor complexity, burn consistency, and burn rate, blending different tobacco leaves to achieve the desired taste profile and smoking experience. High-quality wrapper leaves significantly impact the cigar's aesthetic and draw, while filler leaves contribute primarily to the cigar's flavor, strength, and overall smoking characteristics.

Consumer Preferences and Industry Trends

Wrapper grade tobacco is prized for its fine texture, elasticity, and uniform color, making it the preferred choice for premium cigars among consumers seeking a smooth, visually appealing smoking experience. Filler grade tobacco, composed of various leaf types for flavor and strength, attracts smokers who prioritize robust taste and complexity over appearance. Industry trends show a growing demand for high-quality wrapper leaf due to increasing consumer interest in artisanal and boutique cigars, while filler tobacco production adapts to diverse blends catering to evolving flavor preferences.

Wrapper grade vs filler grade tobacco Infographic

libmatt.com

libmatt.com