Cellulose acetate filters provide superior filtration efficiency and are commonly used in cigarettes due to their biodegradability and smooth draw, while paper filters often offer less filtration and a harsher smoking experience. Choosing a cellulose acetate filter can enhance Your smoking comfort by reducing tar and contaminants more effectively compared to traditional paper filters.

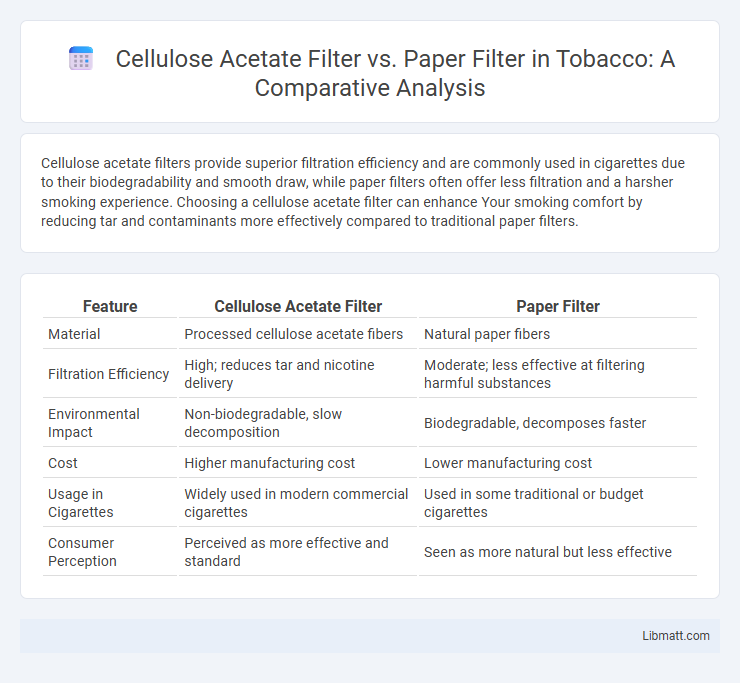

Table of Comparison

| Feature | Cellulose Acetate Filter | Paper Filter |

|---|---|---|

| Material | Processed cellulose acetate fibers | Natural paper fibers |

| Filtration Efficiency | High; reduces tar and nicotine delivery | Moderate; less effective at filtering harmful substances |

| Environmental Impact | Non-biodegradable, slow decomposition | Biodegradable, decomposes faster |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Usage in Cigarettes | Widely used in modern commercial cigarettes | Used in some traditional or budget cigarettes |

| Consumer Perception | Perceived as more effective and standard | Seen as more natural but less effective |

Introduction to Filter Materials

Cellulose acetate filters consist of synthetic fibers derived from cellulose, offering high filtration efficiency and consistent pore size, making them ideal for capturing fine particles. Paper filters, made from natural cellulose fibers, provide excellent filtration with high dirt-holding capacity but may have less uniform pore structure compared to cellulose acetate. Your choice between these filter materials depends on specific applications requiring either enhanced mechanical strength and clarity or cost-effectiveness and biodegradability.

Composition of Cellulose Acetate Filters

Cellulose acetate filters are composed primarily of cellulose fibers chemically treated with acetic acid to form a semi-synthetic material that offers superior filtration and durability compared to paper filters. Unlike paper filters made from cellulose pulp, cellulose acetate filters maintain structural integrity and resist moisture, enhancing performance in tobacco smoke filtration. You benefit from a smoother draw and reduced tar intake due to the uniform pore structure and chemical stability of cellulose acetate.

Structure and Properties of Paper Filters

Paper filters consist of cellulose fibers arranged in a tightly interwoven matrix, providing a porous structure that effectively traps particulate matter. Their hydrophilic properties enable efficient absorption and retention of liquids, making them suitable for various filtration applications. The inherent biodegradability and cost-effectiveness of paper filters contribute to their widespread use in industrial and household settings.

Filtration Efficiency Comparison

Cellulose acetate filters exhibit higher filtration efficiency compared to paper filters due to their uniform fiber structure, which allows better capture of fine particles and contaminants. The microporous nature of cellulose acetate enhances airflow while maintaining superior particulate retention, making it ideal for applications requiring precise filtration. Conversely, paper filters generally have larger pore sizes, resulting in lower filtration accuracy and shorter lifespan under high particulate loads.

Environmental Impact and Biodegradability

Cellulose acetate filters, commonly used in cigarettes, pose significant environmental challenges due to their slow degradation rate, often persisting for years as non-biodegradable plastic waste. In contrast, paper filters decompose more rapidly and have a lower environmental footprint, making them a more eco-friendly alternative. The accumulation of cellulose acetate filters contributes heavily to microplastic pollution, whereas paper filters break down into organic matter that can be assimilated by natural ecosystems.

User Experience and Taste Effects

Cellulose acetate filters provide a smoother smoke by reducing harshness and effectively filtering tar, enhancing overall user comfort compared to paper filters, which tend to produce a stronger, more robust flavor due to less filtration. The porous structure of cellulose acetate helps maintain consistent airflow, resulting in a cleaner taste and less irritation for smokers. Paper filters often impart a slight paper taste, which can alter the flavor profile, whereas cellulose acetate filters preserve the tobacco's natural taste more faithfully.

Manufacturing Processes and Costs

Cellulose acetate filters are produced through a complex acetylation process involving cellulose fibers, which increases manufacturing costs due to specialized chemical treatments and equipment. Paper filters, on the other hand, are manufactured using a simpler, more cost-effective pulping and pressing process that utilizes readily available cellulose fibers. When choosing between the two, Your decision may depend on cost considerations, as paper filters generally offer a more affordable production method compared to the higher expenses associated with cellulose acetate filters.

Health Implications of Each Filter Type

Cellulose acetate filters, commonly used in cigarettes, can reduce tar and nicotine inhalation but may degrade into harmful byproducts when exposed to high temperatures, potentially impacting respiratory health. Paper filters, while simpler, do not effectively block tar and fine particulates, leading to greater exposure to carcinogens and toxins during smoking. Studies show that cellulose acetate filters may alter the chemical composition of smoke, resulting in different health risks compared to paper filters, which primarily allow unfiltered smoke accumulation.

Regulatory and Industry Standards

Cellulose acetate filters comply with stringent regulatory standards such as the USP (United States Pharmacopeia) and ISO 9001 certifications, ensuring high purity and biocompatibility for pharmaceutical and laboratory use. Paper filters often meet ASTM (American Society for Testing and Materials) standards suitable for environmental and industrial testing, but may lack the consistent filtration efficiency required in medical applications. Your choice between cellulose acetate and paper filters should consider these regulatory frameworks to align with industry-specific quality and safety requirements.

Future Trends in Filter Technology

Cellulose acetate filters are increasingly favored over traditional paper filters due to their superior biodegradability and enhanced filtration efficiency, aligning with growing environmental regulations and consumer demand for sustainable products. Innovations in nanotechnology are driving the development of cellulose acetate filters with improved pore structure and selective filtration capabilities, surpassing those of paper filters. Future trends indicate a shift toward hybrid filters combining cellulose acetate with advanced materials to boost performance in air and liquid filtration applications.

Cellulose acetate filter vs paper filter Infographic

libmatt.com

libmatt.com