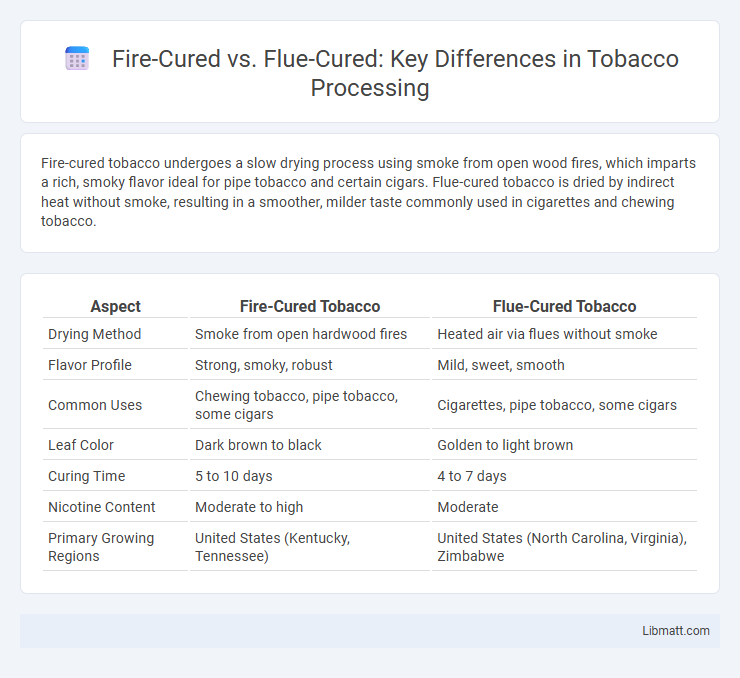

Fire-cured tobacco undergoes a slow drying process using smoke from open wood fires, which imparts a rich, smoky flavor ideal for pipe tobacco and certain cigars. Flue-cured tobacco is dried by indirect heat without smoke, resulting in a smoother, milder taste commonly used in cigarettes and chewing tobacco.

Table of Comparison

| Aspect | Fire-Cured Tobacco | Flue-Cured Tobacco |

|---|---|---|

| Drying Method | Smoke from open hardwood fires | Heated air via flues without smoke |

| Flavor Profile | Strong, smoky, robust | Mild, sweet, smooth |

| Common Uses | Chewing tobacco, pipe tobacco, some cigars | Cigarettes, pipe tobacco, some cigars |

| Leaf Color | Dark brown to black | Golden to light brown |

| Curing Time | 5 to 10 days | 4 to 7 days |

| Nicotine Content | Moderate to high | Moderate |

| Primary Growing Regions | United States (Kentucky, Tennessee) | United States (North Carolina, Virginia), Zimbabwe |

Introduction to Tobacco Curing Methods

Fire-cured and flue-cured tobacco represent two distinct curing methods used to develop specific flavor profiles and moisture content in tobacco leaves. Fire-curing involves exposing leaves to smoke from smoldering hardwoods, imparting a robust, smoky flavor ideal for pipe and chewing tobacco. Flue-curing uses indirect heat through flue pipes, producing a milder, sweeter leaf preferred for cigarettes and premium cigars.

What is Fire-Cured Tobacco?

Fire-cured tobacco is a type of tobacco leaf cured using smoke from a low-burning hardwood fire, which imparts a distinctive smoky flavor and aroma. This curing process typically takes place in specially constructed barns where controlled fires are maintained to dry the tobacco over several days. Fire-cured tobacco is commonly used in products like pipe tobacco, chewing tobacco, and certain cigars due to its rich, robust taste profile.

What is Flue-Cured Tobacco?

Flue-cured tobacco is a type of tobacco leaf dried using a controlled heat system where hot air circulates through enclosed barns, preventing direct smoke exposure and preserving its bright, mild flavor. This curing process enhances the sugar content, resulting in a sweeter, smoother tobacco commonly used in cigarettes. You benefit from the distinctive aroma and balanced nicotine levels that flue-cured tobacco provides, contrasting with the smoky, robust character of fire-cured varieties.

Key Differences Between Fire-Cured and Flue-Cured

Fire-cured tobacco undergoes slow drying over open wood fires, imparting a smoky aroma and robust flavor, while flue-cured tobacco is dried using heated air without direct smoke, resulting in a milder taste and lighter color. The curing environment for fire-cured tobacco is open and smoky, enhancing nicotine content and durability, whereas flue-curing uses enclosed barns with controlled temperatures, preserving sugar content and smoothness. Understanding these key differences helps you select the appropriate tobacco type for your desired flavor profile and usage.

Flavor Profiles: Fire-Cured vs Flue-Cured

Fire-cured tobacco delivers a robust, smoky flavor profile with deep, earthy notes that appeal to those seeking a bold and rich taste experience. Flue-cured tobacco offers a milder, sweeter flavor characterized by delicate grassy and citrusy undertones, ideal for users who prefer a smoother, more refined smoke. Your choice between these curing methods directly influences the intensity and character of the tobacco's flavor, catering to different palates and preferences.

Impact on Tobacco Aroma and Taste

Fire-cured tobacco undergoes a slow drying process using hardwood smoke, imparting a rich, smoky aroma and robust, earthy flavor prized in pipe and chewing tobaccos. Flue-cured tobacco dries in controlled heat without smoke exposure, preserving a sweeter, milder taste with subtle floral and citrus notes typical of cigarette tobacco. These curing methods significantly shape the sensory profile, with fire-cured varieties offering a distinctive smoky complexity and flue-cured types delivering a cleaner, more delicate flavor.

Regional Production of Fire-Cured and Flue-Cured Tobacco

Fire-cured tobacco is predominantly produced in the Appalachian regions of the United States, such as Kentucky and Tennessee, where barns are heated with open fires to impart a distinctive smoky flavor. Flue-cured tobacco, in contrast, is mainly grown in the southeastern states like North Carolina and Virginia, using indirect heat sources to preserve a smooth, mild aroma. Your choice between fire-cured and flue-cured tobacco will depend on the desired flavor profile influenced by these specific regional curing methods.

Uses in Cigars, Cigarettes, and Other Products

Fire-cured tobacco, known for its rich, smoky flavor, is primarily used in pipe tobacco, cigars, and chewing tobacco, enhancing products that benefit from a robust aroma. Flue-cured tobacco, with its milder and sweeter profile, dominates the cigarette industry due to its smoothness and burn qualities, making it ideal for mass-produced cigarettes. Both types also contribute to niche markets, such as premium cigar blends and specialty tobacco products, offering unique flavor profiles tailored to consumer preferences.

Health Implications and Chemical Differences

Fire-cured tobacco undergoes a slow drying process using smoke from smoldering wood, resulting in higher levels of polycyclic aromatic hydrocarbons (PAHs) and other carcinogens compared to flue-cured tobacco, which is dried using controlled heat without direct smoke exposure. The chemical composition of fire-cured tobacco includes elevated nicotine and tar content, potentially increasing health risks such as respiratory issues and cancer, whereas flue-cured tobacco tends to have lower levels of harmful chemicals due to its cleaner curing method. Understanding these differences allows you to make more informed decisions regarding tobacco products and their impact on your health.

Choosing Between Fire-Cured and Flue-Cured Tobacco

Fire-cured tobacco undergoes a slow drying process using open flames, which imparts a rich, smoky flavor ideal for pipe tobacco and some cigars. Flue-cured tobacco is dried using heated air without smoke, preserving a mild, sweet taste often preferred in cigarettes. When choosing between fire-cured and flue-cured tobacco, consider your desired flavor profile and smoking experience to find the option that best suits your preferences.

Fire-cured vs Flue-cured Infographic

libmatt.com

libmatt.com