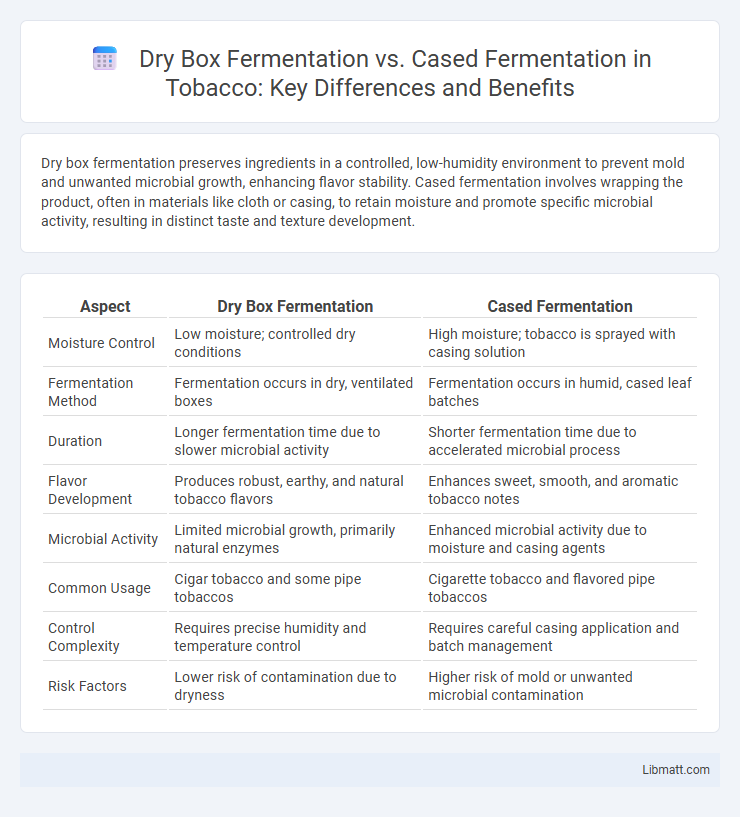

Dry box fermentation preserves ingredients in a controlled, low-humidity environment to prevent mold and unwanted microbial growth, enhancing flavor stability. Cased fermentation involves wrapping the product, often in materials like cloth or casing, to retain moisture and promote specific microbial activity, resulting in distinct taste and texture development.

Table of Comparison

| Aspect | Dry Box Fermentation | Cased Fermentation |

|---|---|---|

| Moisture Control | Low moisture; controlled dry conditions | High moisture; tobacco is sprayed with casing solution |

| Fermentation Method | Fermentation occurs in dry, ventilated boxes | Fermentation occurs in humid, cased leaf batches |

| Duration | Longer fermentation time due to slower microbial activity | Shorter fermentation time due to accelerated microbial process |

| Flavor Development | Produces robust, earthy, and natural tobacco flavors | Enhances sweet, smooth, and aromatic tobacco notes |

| Microbial Activity | Limited microbial growth, primarily natural enzymes | Enhanced microbial activity due to moisture and casing agents |

| Common Usage | Cigar tobacco and some pipe tobaccos | Cigarette tobacco and flavored pipe tobaccos |

| Control Complexity | Requires precise humidity and temperature control | Requires careful casing application and batch management |

| Risk Factors | Lower risk of contamination due to dryness | Higher risk of mold or unwanted microbial contamination |

Introduction to Coffee Fermentation Techniques

Dry box fermentation preserves coffee cherries in controlled, low-oxygen environments to enhance fruity and complex flavor profiles by limiting microbial activity. Cased fermentation involves wrapping coffee parchment in banana leaves or other natural materials, promoting selective microbial growth that intensifies sweetness and acidity nuances. Both methods optimize fermentation conditions to influence bean chemistry and develop distinctive flavor characteristics in specialty coffee.

What is Dry Box Fermentation?

Dry box fermentation is a controlled process where mushrooms are cultivated in a low-humidity environment to reduce moisture content and minimize contamination risks. This method contrasts with cased fermentation, which involves covering the substrate with a casing layer to maintain humidity and promote pinning. Your choice between these techniques depends on the specific mushroom species and desired yield outcomes.

What is Cased Fermentation?

Cased fermentation involves covering cocoa beans with a layer of moist material to create a controlled environment that promotes optimal microbial activity, enhancing flavor and aroma development. This method maintains the beans' moisture and temperature, crucial factors for the fermentation process, resulting in a more uniform and high-quality end product. Your choice between dry box fermentation and cased fermentation will depend on factors like desired flavor profile, fermentation control, and available resources.

Key Differences Between Dry Box and Cased Fermentation

Dry box fermentation involves fermenting tobacco leaves in a controlled, low-humidity environment that minimizes moisture content, preserving leaf texture and enhancing specific flavor profiles. Cased fermentation introduces a casing solution, typically containing sugars, flavor enhancers, or humectants, which promotes microbial activity and accelerates the breakdown of leaf compounds, resulting in a smoother, milder tobacco. The primary differences lie in moisture management and chemical treatment, with dry box fermentation focusing on precise environmental control, while cased fermentation relies on added substances to modify the leaf's chemical composition and fermentation dynamics.

Advantages of Dry Box Fermentation

Dry box fermentation offers superior control over humidity and temperature, ensuring consistent fermentation conditions that reduce the risk of contamination and mold growth. This method enhances flavor development by allowing precise modulation of airflow and moisture levels, resulting in a more uniform and higher-quality product compared to cased fermentation. Your fermentation process benefits from increased efficiency and reduced spoilage, making dry box fermentation an advantageous choice for premium tobacco curing.

Benefits of Cased Fermentation

Cased fermentation offers enhanced control over moisture levels, promoting uniform yeast activity and richer flavor development in tobacco leaves. It allows for precise addition of sugars, flavors, and other additives, resulting in a more consistent and aromatic final product. This method also reduces the risk of contamination and spoilage compared to dry box fermentation, improving overall tobacco quality.

Flavor Profile Comparison

Dry box fermentation emphasizes controlled humidity and consistent temperature, resulting in a cleaner, more uniform flavor profile with subtle earthy and floral notes. Cased fermentation, involving a protective casing layer, promotes slower microbial activity that enhances complexity and depth, producing richer, more robust flavors with pronounced fruity and spicy undertones. Understanding these differences helps you select the ideal fermentation method to achieve your desired taste characteristics.

Impact on Coffee Quality and Consistency

Dry box fermentation preserves more of the coffee's fruity and acidic notes by controlling oxygen exposure and moisture levels, resulting in brighter and cleaner flavor profiles. Cased fermentation, where beans are fermented with their pulp intact, often produces richer, heavier-bodied coffees but with greater variability in flavor due to uneven fermentation. Your choice between these methods significantly affects coffee quality and consistency, with dry box fermentation offering more predictable results for specialty coffee producers.

Environmental and Economic Considerations

Dry box fermentation requires less energy and water consumption compared to cased fermentation, making it a more environmentally sustainable option. The controlled environment minimizes waste and reduces the need for frequent monitoring, lowering operational costs. You can achieve significant economic benefits with dry box fermentation through higher resource efficiency and reduced labor expenses.

Choosing the Right Fermentation Method

Dry box fermentation offers precise humidity and temperature control, ideal for curing premium cigars with consistent flavor profiles, while cased fermentation relies on external leaf coatings to slow oxidation and develop complexity. Your choice depends on desired flavor intensity and aging time, with dry box providing a cleaner, more controlled environment and cased fermentation imparting richer, subtler notes through extended aging. Evaluating these methods ensures optimal tobacco quality tailored to your specific fermentation goals.

Dry box fermentation vs cased fermentation Infographic

libmatt.com

libmatt.com