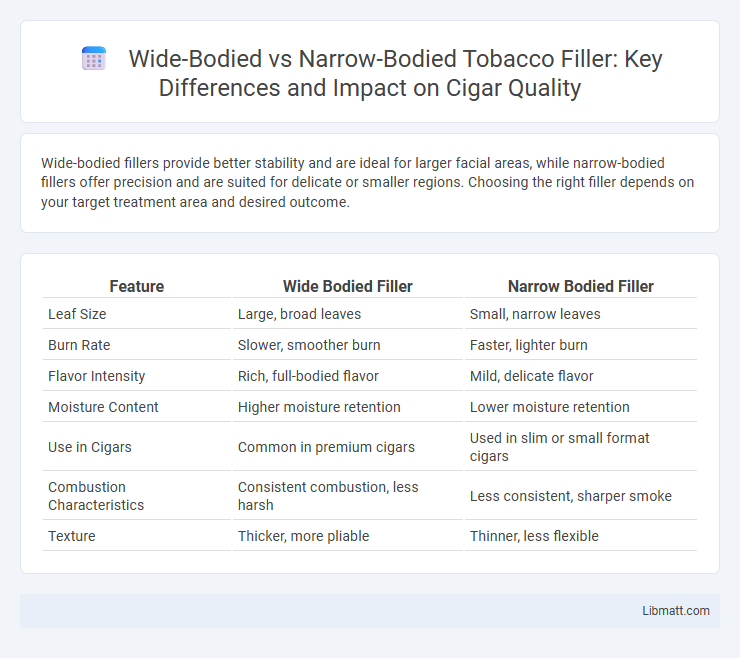

Wide-bodied fillers provide better stability and are ideal for larger facial areas, while narrow-bodied fillers offer precision and are suited for delicate or smaller regions. Choosing the right filler depends on your target treatment area and desired outcome.

Table of Comparison

| Feature | Wide Bodied Filler | Narrow Bodied Filler |

|---|---|---|

| Leaf Size | Large, broad leaves | Small, narrow leaves |

| Burn Rate | Slower, smoother burn | Faster, lighter burn |

| Flavor Intensity | Rich, full-bodied flavor | Mild, delicate flavor |

| Moisture Content | Higher moisture retention | Lower moisture retention |

| Use in Cigars | Common in premium cigars | Used in slim or small format cigars |

| Combustion Characteristics | Consistent combustion, less harsh | Less consistent, sharper smoke |

| Texture | Thicker, more pliable | Thinner, less flexible |

Introduction to Wide Bodied vs Narrow Bodied Filler

Wide bodied fillers feature a larger gauge and greater cross-sectional area, enabling higher volume flow rates ideal for rapid deposition in heavy-duty applications. Narrow bodied fillers offer precision and control with a smaller gauge, suited for delicate welds and thin materials requiring minimal heat input. Selecting between wide and narrow bodied fillers depends on welding speed, material thickness, and desired weld bead profile.

Understanding Filler Body Types

Wide bodied fillers provide greater coverage and smoother blending for large areas, making them ideal for substantial repairs and surface leveling. Narrow bodied fillers are designed for precision work on smaller cracks or dents, allowing you to target fine details with minimal excess. Understanding your project's scale and surface requirements helps you choose the right filler body type for efficient and effective repairs.

Composition Differences of Wide and Narrow Bodied Fillers

Wide bodied fillers contain larger particle sizes and a higher volume of resin compared to narrow bodied fillers, resulting in increased bulk and improved gap-filling properties. Narrow bodied fillers use finer particles to create smoother surfaces with enhanced finishing qualities, making them ideal for fine repairs and detailing. Your choice between wide and narrow bodied fillers depends on the specific requirements for texture, durability, and application thickness.

Performance Characteristics Compared

Wide bodied fillers offer higher throughput and enhanced durability due to their increased surface area, making them ideal for large-scale industrial applications. Narrow bodied fillers provide greater precision and control in smaller or more intricate operations, ensuring minimal waste and improved accuracy in your production line. Performance characteristics such as flow rate, heat retention, and material compatibility vary significantly, requiring careful consideration based on the specific demands of your project.

Application Areas for Each Filler Type

Wide bodied fillers are ideal for heavy-duty applications such as automotive panels, aerospace parts, and large industrial equipment where surface leveling and gap filling are critical. Narrow bodied fillers suit precision tasks including small repairs, fine detailing, and delicate surfaces like wooden furniture or intricate metalwork. Understanding your project's scale and surface requirements will help determine which filler type ensures optimal adhesion and finish quality.

Pros and Cons: Wide Bodied vs Narrow Bodied Fillers

Wide bodied fillers offer higher storage capacity and better payload efficiency, making them ideal for long-haul routes and large volume transport, but they may face restrictions at smaller airports and incur higher operating costs. Narrow bodied fillers provide greater route flexibility, faster turnaround times, and lower fuel consumption per flight, which benefits regional and short-haul operations, though they sacrifice cargo volume and may require more frequent trips to transport the same amount of goods. Your choice depends on balancing volume requirements with operational constraints and cost efficiency for your specific logistics needs.

Compatibility with Substrates and Paints

Wide bodied fillers offer superior compatibility with rough or uneven substrates, providing excellent adhesion and filling larger imperfections, which is ideal for automotive or industrial surfaces requiring durable finishes. Narrow bodied fillers are optimized for smooth, fine surfaces, enabling better integration with thin coats of paint and primers, thereby reducing the risk of cracking or peeling. Your choice should align with the substrate texture and the type of paint system used to ensure optimal bonding and finish quality.

Typical Use Cases and Industries

Wide bodied fillers are commonly used in industries requiring high-speed packaging of larger volume products, such as beverages, chemicals, and food processing, where container sizes range from 5 liters to bulk quantities. Narrow bodied fillers excel in pharmaceutical, cosmetic, and small-scale food industries, handling smaller containers like vials, bottles, and tubes with precise volume control. Both types are essential in sectors prioritizing either throughput efficiency or accuracy in filling small doses.

Cost and Availability Considerations

Wide bodied fillers typically incur higher costs due to increased material usage and specialized manufacturing processes, while narrow bodied fillers offer more economical options with easier availability in standard sizes. The availability of wide bodied fillers is often limited to niche markets, making lead times longer compared to the commonly stocked narrow bodied fillers found in mass production supply chains. Businesses must weigh budget constraints against project requirements, as narrow bodied options provide cost-effective solutions with widespread sourcing, whereas wide bodied fillers may justify their expense through better performance or specific application needs.

Choosing the Right Filler for Your Project

Selecting the right filler for your project depends on the application surface and desired finish quality; wide bodied fillers offer greater coverage for larger surface areas and deeper imperfections, while narrow bodied fillers provide precision for fine detailing and small repairs. Consider factors such as drying time, sanding ease, and paint compatibility to ensure optimal adhesion and durability. Using the appropriate filler type enhances structural integrity and results in a smoother, professional finish.

Wide bodied filler vs narrow bodied Infographic

libmatt.com

libmatt.com