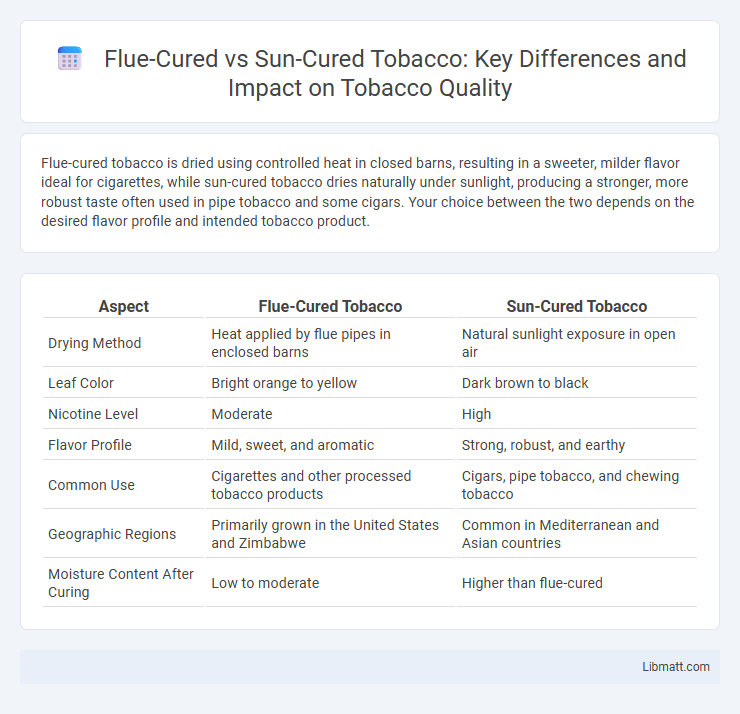

Flue-cured tobacco is dried using controlled heat in closed barns, resulting in a sweeter, milder flavor ideal for cigarettes, while sun-cured tobacco dries naturally under sunlight, producing a stronger, more robust taste often used in pipe tobacco and some cigars. Your choice between the two depends on the desired flavor profile and intended tobacco product.

Table of Comparison

| Aspect | Flue-Cured Tobacco | Sun-Cured Tobacco |

|---|---|---|

| Drying Method | Heat applied by flue pipes in enclosed barns | Natural sunlight exposure in open air |

| Leaf Color | Bright orange to yellow | Dark brown to black |

| Nicotine Level | Moderate | High |

| Flavor Profile | Mild, sweet, and aromatic | Strong, robust, and earthy |

| Common Use | Cigarettes and other processed tobacco products | Cigars, pipe tobacco, and chewing tobacco |

| Geographic Regions | Primarily grown in the United States and Zimbabwe | Common in Mediterranean and Asian countries |

| Moisture Content After Curing | Low to moderate | Higher than flue-cured |

Introduction to Flue-Cured and Sun-Cured Tobacco

Flue-cured tobacco is primarily grown in regions like the United States, curing through controlled heating that preserves its bright color and mild flavor, making it ideal for cigarettes. Sun-cured tobacco, popular in Mediterranean countries, dries naturally under sunlight, resulting in a darker leaf with stronger, earthy flavors commonly used in products like snuff and cigars. Understanding the distinct curing processes helps you appreciate the unique qualities and applications of each tobacco type in the market.

Historical Background of Tobacco Curing Methods

Flue-cured tobacco, developed in the early 19th century, revolutionized tobacco processing by drying leaves in controlled heated air environments, preserving sweetness and reducing harshness. Sun-cured tobacco, one of the oldest methods dating back centuries, relies on natural sunlight and heat to cure leaves, producing a distinct flavor often used in Mediterranean and Middle Eastern tobaccos. Understanding these historical curing techniques helps you appreciate the evolution of tobacco flavor profiles and cultivation practices.

Overview of Flue-Curing Process

The flue-curing process involves drying tobacco leaves in a controlled environment using heated air circulated through flues, maintaining temperatures between 65degC and 70degC. This method preserves high sugar content and enhances the leaf's natural sweetness and aroma, resulting in a milder flavor profile compared to sun-cured tobacco. Flue-cured tobacco is primarily used in cigarette production due to its light, smooth characteristics.

Overview of Sun-Curing Process

Sun-cured tobacco undergoes a natural drying process where leaves are hung in open barns exposed to direct sunlight, promoting slower moisture loss compared to flue-curing. This method enhances the tobacco's sugar content and imparts a distinctive, mild flavor with lower nicotine levels, making it preferable for oriental blends. Your choice between sun-cured and flue-cured tobacco depends on flavor preferences and desired chemical composition.

Key Differences in Chemical Composition

Flue-cured tobacco typically contains higher sugar content and lower nicotine levels compared to sun-cured tobacco, which is characterized by elevated nicotine and alkaloid concentrations due to its natural drying process. The curing method significantly influences the chemical profile; flue-curing preserves carbohydrates resulting in a sweeter taste, while sun-curing leads to increased polyphenols and reduced sugar content. These variations impact the flavor, aroma, and combustion properties, making the chemical composition of flue-cured and sun-cured tobacco distinctly different.

Taste and Flavor Profiles Compared

Flue-cured tobacco offers a mild, bright flavor with a natural sweetness and low bitterness due to its controlled heating process, which preserves volatile sugars and reduces harshness. Sun-cured tobacco develops a richer, more robust taste characterized by earthy, smoky, and spicy notes, attributed to the direct sun exposure that intensifies chemical transformations during curing. These distinct flavor profiles influence their preferred uses in cigarettes for flue-cured and cigars or pipe tobacco for sun-cured varieties.

Impact on Nicotine Content

Flue-cured tobacco typically exhibits higher nicotine content due to the controlled drying process that preserves alkaloids more effectively than sun-cured methods. Sun-cured tobacco, exposed to natural sunlight, often results in lower nicotine levels as prolonged drying and environmental factors can degrade nicotine compounds. The choice between flue-cured and sun-cured tobacco significantly influences the chemical profile and potency of nicotine in the final product.

Regional Preferences and Cultivation Areas

Flue-cured tobacco is predominantly grown in regions like North Carolina and Virginia, where the controlled heat curing process enhances its mild, sweet flavor favored in American cigarettes. Sun-cured tobacco thrives in Mediterranean climates such as Turkey and Greece, producing a darker, stronger leaf preferred for oriental blends and pipe tobacco. Your choice between flue-cured and sun-cured varieties depends on the regional cultivation conditions that influence leaf characteristics and flavor profiles.

Market Demand and Economic Impact

Flue-cured tobacco dominates global markets due to its consistent quality and preferred use in cigarettes, driving higher demand and generating significant revenue in major producing countries like the United States and Zimbabwe. Sun-cured tobacco, prized in specialty products and traditional markets, commands premium prices but has a smaller market share, primarily impacting rural economies and niche export sectors. Both curing methods contribute to employment and regional economic stability, with flue-cured cultivation supporting large-scale agribusiness and sun-cured farming sustaining artisanal and smallholder communities.

Health Considerations and Consumer Choices

Flue-cured tobacco undergoes a controlled drying process that reduces certain harmful compounds compared to sun-cured tobacco, which is naturally dried and may retain higher levels of tar and nicotine. Health considerations often lead consumers to prefer flue-cured tobacco due to its smoother flavor and slightly lower toxin content, impacting choices for those seeking a less harsh smoking experience. Your decision between these tobacco types should weigh the differences in chemical composition and potential health risks associated with their curing methods.

flue-cured tobacco vs sun-cured tobacco Infographic

libmatt.com

libmatt.com