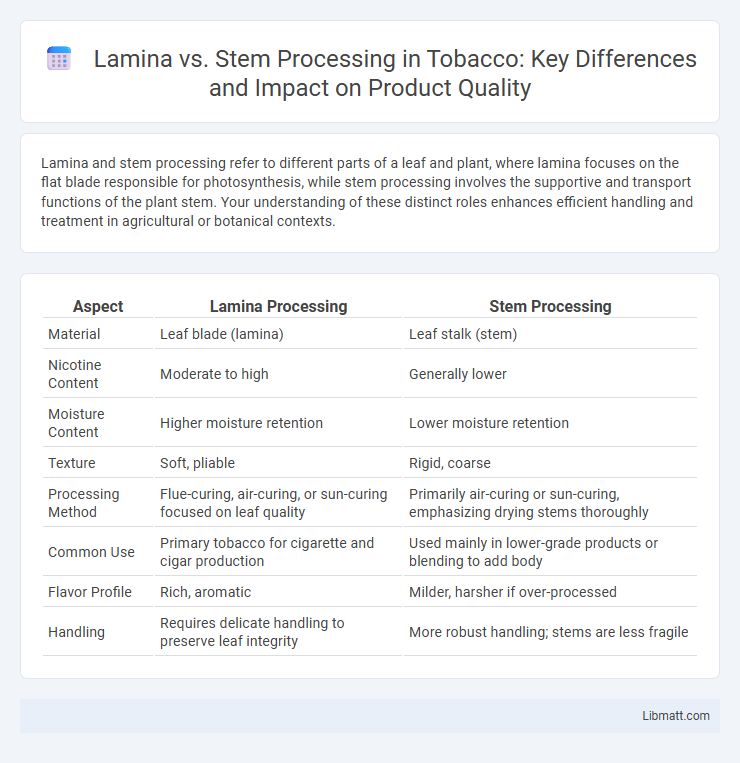

Lamina and stem processing refer to different parts of a leaf and plant, where lamina focuses on the flat blade responsible for photosynthesis, while stem processing involves the supportive and transport functions of the plant stem. Your understanding of these distinct roles enhances efficient handling and treatment in agricultural or botanical contexts.

Table of Comparison

| Aspect | Lamina Processing | Stem Processing |

|---|---|---|

| Material | Leaf blade (lamina) | Leaf stalk (stem) |

| Nicotine Content | Moderate to high | Generally lower |

| Moisture Content | Higher moisture retention | Lower moisture retention |

| Texture | Soft, pliable | Rigid, coarse |

| Processing Method | Flue-curing, air-curing, or sun-curing focused on leaf quality | Primarily air-curing or sun-curing, emphasizing drying stems thoroughly |

| Common Use | Primary tobacco for cigarette and cigar production | Used mainly in lower-grade products or blending to add body |

| Flavor Profile | Rich, aromatic | Milder, harsher if over-processed |

| Handling | Requires delicate handling to preserve leaf integrity | More robust handling; stems are less fragile |

Introduction to Lamina and Stem in Processing

Lamina and stem represent core structural components in plant processing, where the lamina refers to the flat, expanded part of a leaf primarily responsible for photosynthesis and gas exchange. The stem functions as the main support structure, facilitating the transport of water, nutrients, and photosynthates between roots and leaves. Understanding the distinction between lamina and stem is crucial for optimizing mechanical processing techniques, including cutting, drying, and extraction in agricultural and botanical industries.

Structural Differences Between Lamina and Stem

The lamina consists of a thin, flat structure primarily composed of mesophyll cells optimized for photosynthesis, whereas the stem contains thicker vascular tissues like xylem and phloem, providing mechanical support and nutrient transport. Lamina cells are arranged to maximize light capture, while stem cells are organized for strength and flexibility to support the plant body. Understanding these structural differences helps you appreciate how each part functions uniquely within plant physiology.

Functional Roles in Plant Physiology

Lamina primarily serves as the site of photosynthesis, efficiently capturing sunlight and facilitating gas exchange through its broad, flat surface area. The stem provides structural support, transporting water, nutrients, and photosynthates between roots and leaves via xylem and phloem vessels. Understanding the distinct functional roles of lamina and stem can enhance your knowledge of plant physiology and optimize plant care practices.

Key Processing Techniques for Lamina

Key processing techniques for lamina involve precise cutting, drying, and chemical treatments to enhance flexibility, durability, and aesthetic appeal. Laser cutting and die-cutting are common methods to achieve intricate designs and consistent thickness. Controlled drying and impregnation with resins improve dimensional stability and resistance to environmental factors.

Common Processing Methods for Stem

Common processing methods for stem include retting, decortication, and crushing, which help separate fibers from woody material for textile or industrial use. Mechanical processing like carding and combing further refines the stem fibers, enhancing their strength and flexibility. Your choice of processing technique directly affects the quality and usability of the final stem fibers.

Chemical Composition: Lamina vs Stem

The lamina typically contains higher concentrations of chlorophyll and carotenoids essential for photosynthesis, whereas the stem has increased levels of structural compounds like lignin and cellulose to provide support and transport nutrients. Stems exhibit greater amounts of hemicellulose and pectin, contributing to flexibility and rigidity balance, compared to the lamina's softer, more photosynthetically active tissues. Differential distribution of secondary metabolites in stems helps in defense and mechanical strength, contrasting with the lamina's focus on light absorption and gas exchange.

Impact of Processing on Quality Attributes

Processing lamina versus stem significantly influences the quality attributes of plant-derived products, with lamina often retaining higher levels of bioactive compounds such as polyphenols and antioxidants due to its delicate structure. Stem processing typically involves more intense mechanical and thermal treatments, which can degrade nutritional content and alter texture and color. Optimizing processing parameters for lamina preserves sensory quality and nutritional value, while stem processing requires careful control to minimize quality losses and maintain product consistency.

Industrial Applications of Lamina and Stem Processing

Lamina and stem processing play crucial roles in various industrial applications such as paper manufacturing, biofuel production, and textile industries. Lamina processing is preferred for producing high-quality fibers used in specialty papers and packaging materials, while stem processing primarily supports biomass conversion and pulping for construction and agricultural uses. Your choice between lamina and stem processing affects the efficiency, quality, and environmental impact of the final industrial product.

Challenges in Lamina and Stem Separation

Lamina and stem separation poses challenges due to their similar structural composition and overlapping cellular tissues, which complicate the extraction process. Precise mechanical or enzymatic methods are required to avoid damage and ensure purity in separating lamina, the flat leaf part, from the fibrous stem. Your ability to optimize processing parameters directly impacts the efficiency and quality of lamina and stem separation in agricultural or industrial applications.

Future Trends in Lamina and Stem Processing Technologies

Future trends in lamina and stem processing technologies emphasize the integration of AI-powered automation and advanced robotics to enhance precision and reduce processing time. Innovations in bioengineering and nanotechnology facilitate the development of biodegradable composites derived from lamina and stem fibers, promoting sustainability in manufacturing. Research also focuses on optimized enzymatic treatments and ultrasonic methods to improve fiber extraction efficiency while preserving mechanical properties for industrial applications.

Lamina vs stem (processing) Infographic

libmatt.com

libmatt.com