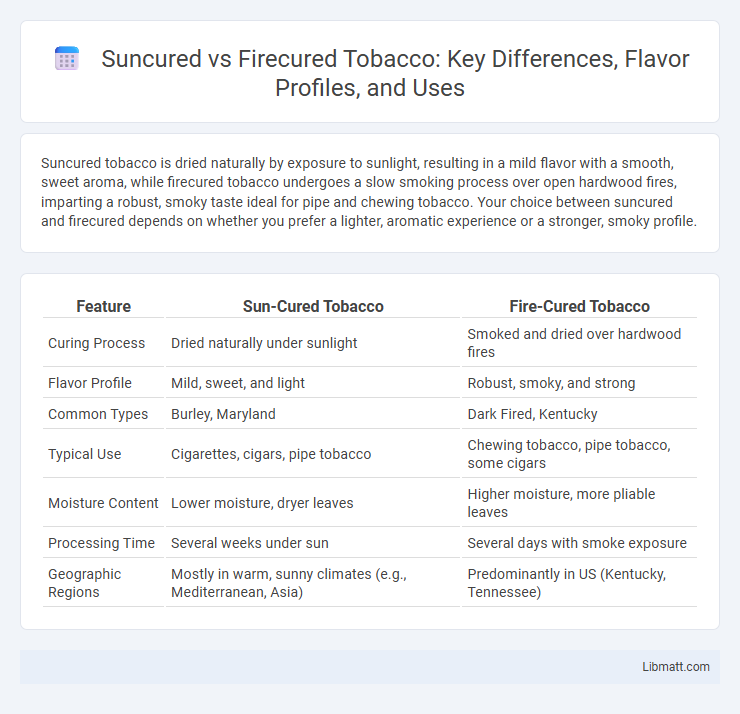

Suncured tobacco is dried naturally by exposure to sunlight, resulting in a mild flavor with a smooth, sweet aroma, while firecured tobacco undergoes a slow smoking process over open hardwood fires, imparting a robust, smoky taste ideal for pipe and chewing tobacco. Your choice between suncured and firecured depends on whether you prefer a lighter, aromatic experience or a stronger, smoky profile.

Table of Comparison

| Feature | Sun-Cured Tobacco | Fire-Cured Tobacco |

|---|---|---|

| Curing Process | Dried naturally under sunlight | Smoked and dried over hardwood fires |

| Flavor Profile | Mild, sweet, and light | Robust, smoky, and strong |

| Common Types | Burley, Maryland | Dark Fired, Kentucky |

| Typical Use | Cigarettes, cigars, pipe tobacco | Chewing tobacco, pipe tobacco, some cigars |

| Moisture Content | Lower moisture, dryer leaves | Higher moisture, more pliable leaves |

| Processing Time | Several weeks under sun | Several days with smoke exposure |

| Geographic Regions | Mostly in warm, sunny climates (e.g., Mediterranean, Asia) | Predominantly in US (Kentucky, Tennessee) |

Introduction to Suncured and Firecured Processes

Suncured tobacco undergoes a natural drying process exposed to direct sunlight, enhancing its sweetness and aroma by preserving natural sugars. Firecured tobacco is dried using smoke from open fires, imparting a smoky, robust flavor ideal for pipe and chewing tobacco. These curing methods significantly influence the chemical composition and final taste profile of the tobacco.

Historical Background of Tobacco Curing

Sun-cured tobacco, historically rooted in regions with abundant sunlight like Turkey and parts of the Mediterranean, relies on natural drying methods to develop a mild flavor profile favored since the Ottoman Empire era. Fire-cured tobacco originated in the southeastern United States during the 18th century, where controlled hardwood smoke was used to dry leaves, imparting a distinctive smoky character essential to traditional Appalachian tobacco products. Both curing methods reflect cultural adaptations to local climate and resources, shaping regional tobacco industries and consumption patterns over centuries.

How Suncuring Works: Methods and Techniques

Suncuring involves drying materials like tobacco leaves or herbs naturally under the sun, utilizing direct solar radiation to reduce moisture content gradually. This method relies on controlled exposure and ambient temperature to ensure even curing, preserving essential oils and flavors while preventing mold growth. Understanding how suncuring works can help you optimize drying conditions for superior quality and consistent results.

The Firecuring Process: An Overview

The firecuring process involves hanging tobacco leaves in barns where smoldering hardwood fires generate smoke and heat, infusing the leaves with distinct smoky flavors and aroma. Controlled temperatures between 120degF and 150degF enable slow drying while enhancing chemical changes that contribute to the tobacco's characteristic robust, spicy profile. This traditional method contrasts with suncuring, which relies on direct sunlight and results in milder, sweeter tobacco varieties often used in pipe blends and cigars.

Key Differences Between Suncured and Firecured Tobacco

Suncured tobacco is dried naturally under direct sunlight, resulting in a milder flavor and higher sugar content, while firecured tobacco is dried using smoke from open wood fires, producing a robust, smoky taste with lower sugar levels. The moisture content in firecured tobacco tends to be higher due to the curing environment, affecting its burn rate and flavor profile. Suncured tobacco is commonly used in cigars and pipe blends for its smoothness, whereas firecured varieties are preferred in certain types of smokeless tobacco and specialty pipes for their intense aroma.

Impact on Flavor and Aroma Profiles

Sun-cured tobacco undergoes natural drying under direct sunlight, resulting in a milder, sweeter flavor profile with floral and fruity aroma notes. Fire-cured tobacco, exposed to controlled hardwood smoke during drying, develops a robust, smoky flavor with earthy and spicy undertones. The choice between sun-cured and fire-cured significantly influences the tobacco's sensory complexity and aromatic intensity.

Health Implications of Suncured vs Firecured Tobacco

Suncured tobacco undergoes natural drying processes that reduce the presence of harmful chemicals compared to firecured tobacco, which is exposed to smoke from burning wood, increasing tar and toxic compounds. Firecured tobacco typically contains higher levels of carcinogens such as phenols and polycyclic aromatic hydrocarbons, posing greater health risks when used. Your choice between suncured and firecured tobacco can impact your exposure to these dangerous substances, influencing long-term respiratory and cardiovascular health outcomes.

Popular Uses in the Tobacco Industry

Sun-cured tobacco is predominantly used in the production of cigars and pipe tobacco due to its mild flavor and aromatic qualities, which develop through natural drying under sunlight. Fire-cured tobacco, characterized by its smoky and robust flavor, is mainly found in products like chewing tobacco, snuff, and certain types of pipe tobacco, where the intense curing process enhances the taste profile. Both curing methods cater to specific market segments, with sun-cured preferred for traditional cigars and fire-cured favored in smokeless tobacco varieties.

Market Trends and Consumer Preferences

Sun-cured tobacco remains popular in markets valuing natural and traditional curing methods, with consumers preferring its milder flavor and higher sugar content. Fire-cured tobacco, favored in specific regions like Kentucky and Tennessee, appeals to those seeking a stronger, smoky taste profile, especially in pipe and chewing tobacco products. Your choice between sun-cured and fire-cured tobacco can influence market reach, as consumer preferences shift toward unique, artisanal tobacco experiences.

Choosing the Right Curing Method for Quality Tobacco

Sun-cured tobacco undergoes natural drying under direct sunlight, resulting in a lighter flavor profile and lower nicotine content compared to fire-cured tobacco, which is dried using smoke from hardwood fires, imparting a stronger, smoky aroma ideal for pipe and chewing tobacco. Selecting the appropriate curing method depends on the desired tobacco characteristics, with sun-curing favored for milder, aromatic blends and fire-curing preferred for robust, flavorful products. Understanding these differences ensures tobacco producers achieve optimal flavor quality and consumer satisfaction in their final product.

suncured vs firecured Infographic

libmatt.com

libmatt.com