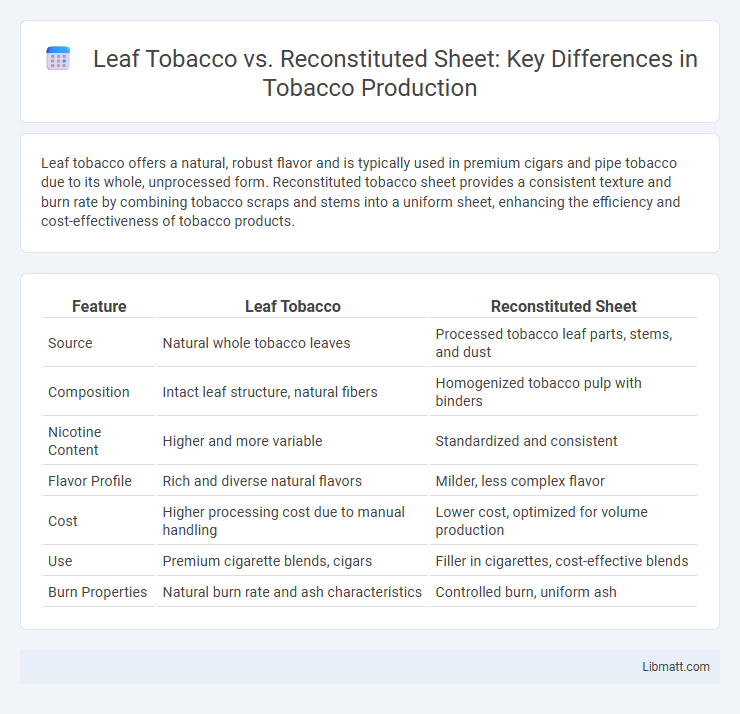

Leaf tobacco offers a natural, robust flavor and is typically used in premium cigars and pipe tobacco due to its whole, unprocessed form. Reconstituted tobacco sheet provides a consistent texture and burn rate by combining tobacco scraps and stems into a uniform sheet, enhancing the efficiency and cost-effectiveness of tobacco products.

Table of Comparison

| Feature | Leaf Tobacco | Reconstituted Sheet |

|---|---|---|

| Source | Natural whole tobacco leaves | Processed tobacco leaf parts, stems, and dust |

| Composition | Intact leaf structure, natural fibers | Homogenized tobacco pulp with binders |

| Nicotine Content | Higher and more variable | Standardized and consistent |

| Flavor Profile | Rich and diverse natural flavors | Milder, less complex flavor |

| Cost | Higher processing cost due to manual handling | Lower cost, optimized for volume production |

| Use | Premium cigarette blends, cigars | Filler in cigarettes, cost-effective blends |

| Burn Properties | Natural burn rate and ash characteristics | Controlled burn, uniform ash |

Introduction to Leaf Tobacco and Reconstituted Sheet

Leaf tobacco consists of carefully cured and processed tobacco leaves known for their natural flavor and combustion properties, often preferred for premium cigars and cigarettes. Reconstituted sheet is made by grinding tobacco scraps into a pulp, then pressing it into uniform sheets, offering cost efficiency and consistent burn quality. Your choice between leaf tobacco and reconstituted sheet impacts the flavor complexity and manufacturing flexibility in tobacco products.

Definition and Composition

Leaf tobacco refers to the natural, whole leaves harvested from the tobacco plant, containing essential fibers, nicotine, and naturally occurring compounds. Reconstituted sheet tobacco is created by recycling tobacco scraps, stems, and dust, which are pulverized and combined with binders and fillers to form a uniform sheet. Your choice between these types influences flavor intensity and combustion properties due to their distinct compositions.

Production Processes Compared

Leaf tobacco undergoes harvesting, curing, and aging, preserving its natural leaf structure and flavor complexity, while reconstituted sheet tobacco is produced by pulping tobacco scraps and stems, then forming uniform sheets through a press and drying process. The former maintains organic leaf properties beneficial for traditional smokers, whereas the latter allows for a consistent, cost-effective tobacco base used in blends or mass-produced cigarettes. Your choice between these types depends on preferences for flavor authenticity or manufacturing efficiency.

Flavor Profile Differences

Leaf tobacco offers a rich, complex flavor profile with natural variations influenced by soil, climate, and curing methods, producing notes ranging from sweet and nutty to earthy and spicy. Reconstituted tobacco sheets provide a more uniform taste, often milder and less nuanced, as they are created by blending tobacco leaf scraps and additives, which can reduce bitterness but also diminish depth. Smokers seeking a bold, authentic flavor tend to prefer leaf tobacco, while those favoring consistency and smoothness often opt for reconstituted sheets.

Chemical Additives and Ingredients

Leaf tobacco contains natural chemical compounds such as nicotine, tar, and various alkaloids inherent to the plant, while reconstituted tobacco sheet involves chemical additives including binding agents, flavor enhancers, and humectants designed to improve consistency and burn quality. The reconstituted sheet also uses starch, sugars, and ammonium compounds to modify combustion and taste profiles, which differ significantly from the chemical composition of pure leaf tobacco. Your choice between the two affects exposure to these added chemicals and the overall smoking experience due to varied ingredient blends.

Cost and Economic Impact

Leaf tobacco typically incurs higher costs due to labor-intensive harvesting and curing processes, impacting overall production expenses. Reconstituted tobacco sheets offer a cost-effective alternative by utilizing tobacco scraps, stems, and dust bound together, reducing waste and lowering material costs. Utilizing reconstituted sheets can optimize your economic efficiency in tobacco product manufacturing by minimizing raw material expenses without compromising product quality.

Environmental Considerations

Leaf tobacco cultivation typically involves extensive land use, water consumption, and pesticide application, contributing to deforestation and soil degradation. Reconstituted tobacco sheets, made from tobacco scraps and stems, reduce waste by reusing byproducts and lessening the demand for fresh leaf harvesting, thereby lowering overall environmental impact. Your choice between these materials can influence sustainability efforts in tobacco production, with reconstituted sheets offering a more eco-friendly alternative.

Usage in Cigarette Manufacturing

Leaf tobacco is primarily used in cigarette manufacturing for its rich flavor and natural composition, providing the core smoking experience with varying blends tailored to consumer preferences. Reconstituted tobacco sheets, made from tobacco pulp combined with stems and dust, offer consistency and uniformity, enhancing burn rate control and reducing waste in mass production. Manufacturers often blend leaf tobacco with reconstituted sheets to balance cost efficiency, flavor complexity, and product quality in cigarettes.

Consumer Perceptions and Preferences

Consumers often perceive leaf tobacco as more natural and premium due to its whole-leaf composition, associating it with richer flavor and higher quality. Reconstituted sheet tobacco, created by processing tobacco scraps into a uniform sheet, may be viewed as less authentic but offers consistency in flavor and burn performance. Your choice between these tobacco forms depends on personal preferences concerning taste, smoothness, and product consistency.

Health and Safety Implications

Leaf tobacco contains natural compounds, including nicotine and tar, which pose significant health risks such as lung cancer and cardiovascular disease due to harmful carcinogens and toxins. Reconstituted tobacco sheets are processed materials combining tobacco residues and additives, potentially introducing additional chemicals and increasing exposure to harmful substances when consumed. Both forms present notable safety concerns, but reconstituted tobacco's altered chemical profile may enhance toxicity and complicate health risk assessments.

Leaf tobacco vs Reconstituted sheet Infographic

libmatt.com

libmatt.com