Microblend fabrics combine ultrafine fibers to create a soft, breathable material ideal for close-to-skin comfort, while macroblend fabrics use thicker fibers offering greater durability and heavier weight. Your choice depends on whether you prioritize lightweight softness or robust, long-lasting wear in your textile needs.

Table of Comparison

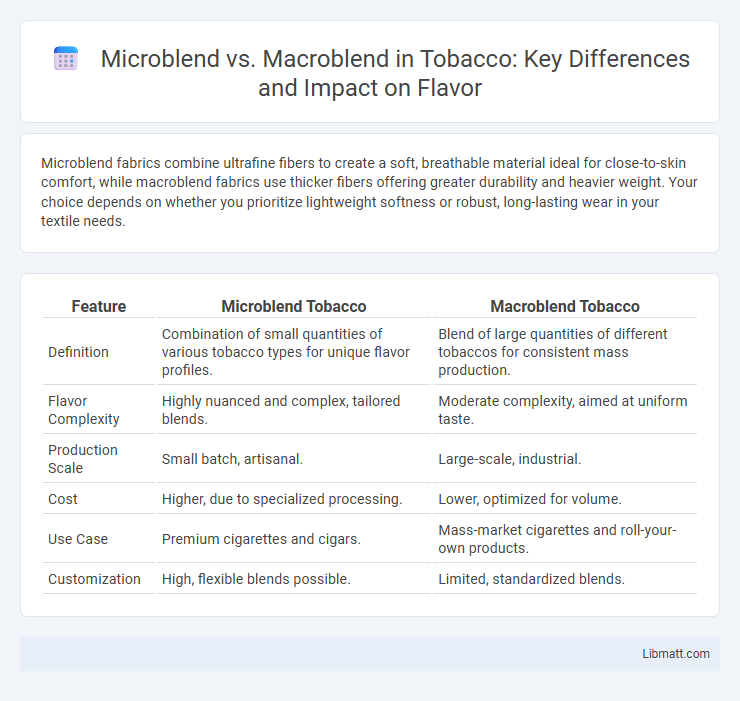

| Feature | Microblend Tobacco | Macroblend Tobacco |

|---|---|---|

| Definition | Combination of small quantities of various tobacco types for unique flavor profiles. | Blend of large quantities of different tobaccos for consistent mass production. |

| Flavor Complexity | Highly nuanced and complex, tailored blends. | Moderate complexity, aimed at uniform taste. |

| Production Scale | Small batch, artisanal. | Large-scale, industrial. |

| Cost | Higher, due to specialized processing. | Lower, optimized for volume. |

| Use Case | Premium cigarettes and cigars. | Mass-market cigarettes and roll-your-own products. |

| Customization | High, flexible blends possible. | Limited, standardized blends. |

Introduction to Microblend and Macroblend

Microblend involves mixing smaller, more refined data segments or materials to achieve heightened precision and uniformity in the final product, which enhances performance and quality control. Macroblend combines larger, bulk quantities, optimizing speed and scale for mass production but often sacrificing detailed consistency. Understanding these blending techniques is crucial for industries prioritizing either meticulous detail or efficient scalability in manufacturing and data processing.

Defining Microblend: Key Characteristics

Microblend refers to small-scale blending processes that combine materials at a fine, often molecular or microscopic level, resulting in uniform distribution and enhanced material properties. Key characteristics include precise control over particle size, homogeneity, and improved performance attributes such as strength, durability, or conductivity. This contrasts with macroblend, which involves larger-scale mixing and less uniformity.

Understanding Macroblend: Essential Features

Macroblend refers to a textile blend where larger, visibly distinct fibers or yarns from different materials are combined, offering unique texture and durability characteristics. These blends enhance fabric strength and can improve performance qualities such as moisture-wicking or insulation. Understanding macroblend helps you select textiles that balance comfort and functionality by leveraging the essential features of each fiber type.

Differences Between Microblend and Macroblend

Microblend fabrics feature ultra-fine fibers typically under one denier, offering superior softness, breathability, and lightweight comfort ideal for performance wear and luxury garments. Macroblend textiles combine fibers of varying diameters, often larger than one denier, resulting in increased durability and versatility suitable for everyday apparel and heavy-duty uses. Understanding the differences between microblend and macroblend helps you select fabrics that balance softness, strength, and application based on your specific clothing needs.

Performance Comparison: Microblend vs Macroblend

Microblend fabrics exhibit superior moisture-wicking and breathability compared to macroblend materials, enhancing athletic performance and comfort during intense physical activity. Macroblend fabrics often excel in durability and cost-effectiveness, making them suitable for everyday wear and heavy-duty applications. The choice between microblend and macroblend depends on balancing performance needs with long-term fabric resilience.

Applications and Use Cases

Microblend fibers, characterized by their finer denier and smoother texture, are predominantly used in high-performance apparel, offering enhanced moisture wicking and breathability ideal for activewear and intimate clothing. Macroblend fibers, combining larger denier fibers, find extensive applications in durable textiles such as upholstery, outerwear, and industrial fabrics due to their strength and abrasion resistance. The choice between microblend and macroblend depends on specific use cases, balancing comfort and durability requirements across fashion, sportswear, and technical textile industries.

Material Composition and Processing

Microblend fabrics consist of fine fibers such as microfiber polyester combined with natural fibers, resulting in a smoother texture and enhanced durability, while macroblend fabrics incorporate coarser fibers like cotton or wool, offering a more textured feel and increased breathability. The processing of microblends involves advanced spinning techniques that tightly weave fibers for lightweight yet strong textiles, whereas macroblends use traditional methods that preserve fiber integrity and promote comfort. Your choice between microblend and macroblend depends on desired fabric performance, including factors like moisture-wicking, strength, and tactile experience.

Advantages and Limitations of Microblend

Microblend technology offers finer metallurgical uniformity than macroblend, resulting in improved mechanical properties and corrosion resistance in materials. You benefit from enhanced performance in aerospace and automotive components due to reduced segregation and fewer defects during manufacturing. However, microblend's limitations include higher production costs and more complex processing requirements compared to macroblend techniques.

Benefits and Drawbacks of Macroblend

Macroblend fibers offer enhanced durability and improved texture uniformity, making them ideal for heavy-use textiles and upholstery. The larger fiber integration often results in better moisture management and increased fabric strength but can sometimes lead to reduced softness and flexibility compared to microblend fabrics. While macroblend fabrics excel in longevity and resilience, their less refined feel may not suit applications requiring delicate or highly breathable materials.

Choosing the Right Blend: Factors to Consider

Choosing the right blend between microblend and macroblend depends on your specific project requirements such as fabric texture, durability, and appearance. Microblends combine fibers at a microscopic level, offering finer texture and smoother finish, ideal for high-performance apparel, while macroblends mix fibers visibly, providing durability and cost efficiency for casual wear or heavy-duty applications. Evaluate your garment's intended use, comfort preferences, and budget to determine whether microblend's subtle integration or macroblend's distinct fiber combination best suits your needs.

microblend vs macroblend Infographic

libmatt.com

libmatt.com