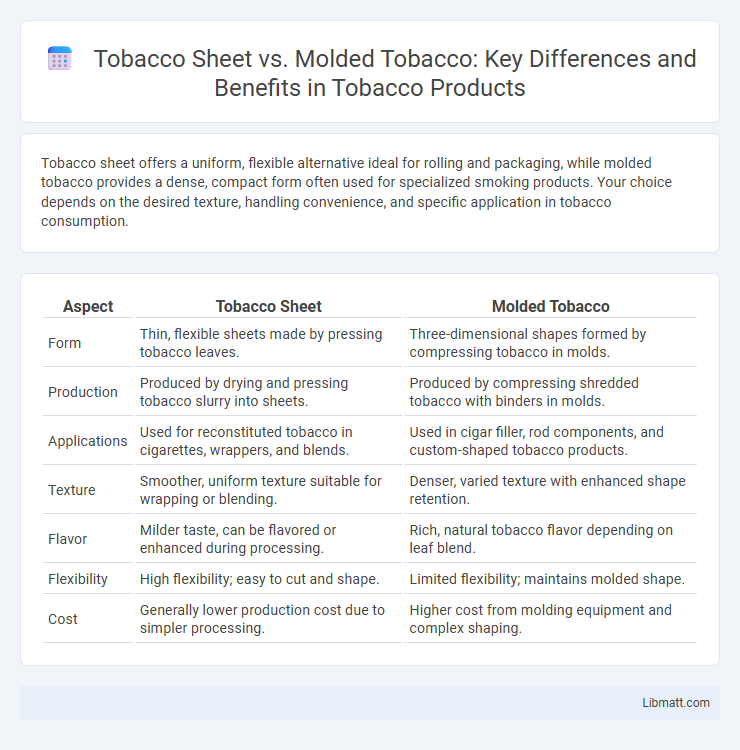

Tobacco sheet offers a uniform, flexible alternative ideal for rolling and packaging, while molded tobacco provides a dense, compact form often used for specialized smoking products. Your choice depends on the desired texture, handling convenience, and specific application in tobacco consumption.

Table of Comparison

| Aspect | Tobacco Sheet | Molded Tobacco |

|---|---|---|

| Form | Thin, flexible sheets made by pressing tobacco leaves. | Three-dimensional shapes formed by compressing tobacco in molds. |

| Production | Produced by drying and pressing tobacco slurry into sheets. | Produced by compressing shredded tobacco with binders in molds. |

| Applications | Used for reconstituted tobacco in cigarettes, wrappers, and blends. | Used in cigar filler, rod components, and custom-shaped tobacco products. |

| Texture | Smoother, uniform texture suitable for wrapping or blending. | Denser, varied texture with enhanced shape retention. |

| Flavor | Milder taste, can be flavored or enhanced during processing. | Rich, natural tobacco flavor depending on leaf blend. |

| Flexibility | High flexibility; easy to cut and shape. | Limited flexibility; maintains molded shape. |

| Cost | Generally lower production cost due to simpler processing. | Higher cost from molding equipment and complex shaping. |

Introduction to Tobacco Sheet and Molded Tobacco

Tobacco sheet refers to thin layers of processed tobacco leaves that are flattened for uniformity and ease of handling in cigarette production, while molded tobacco involves shaping loose tobacco into specific forms using molds to enhance consistency and burn characteristics. Understanding the differences between tobacco sheet and molded tobacco is essential for manufacturers aiming to optimize cigarette quality and production efficiency. Your choice impacts the texture, flavor delivery, and overall smoking experience.

Historical Background of Tobacco Sheet and Molded Forms

Tobacco sheets originated in the 19th century as a method to enhance smoking experience by compressing shredded tobacco into flat, uniform sheets, facilitating easier rolling and consistent burn rates. Molded tobacco forms emerged later, utilizing molds to shape tobacco into compact blocks or sticks, improving portability and storage while maintaining freshness. Your understanding of these traditional processing methods reveals the evolution from flat tobacco sheets to innovative molded forms that cater to varying consumer preferences.

Manufacturing Process: Tobacco Sheet vs Molded Tobacco

Tobacco sheet manufacturing involves pressing moist tobacco leaves into thin, uniform sheets using large rollers, resulting in a consistent thickness ideal for machine-made cigars and cigarrettes. Molded tobacco production shapes rehydrated tobacco strands into three-dimensional forms using molds under heat and pressure, creating custom shapes and textures for specific cigar types and premium products. The sheet process emphasizes efficiency and uniformity, while molding focuses on craft and unique tobacco forms tailored for specialized uses.

Ingredient Composition and Additives

Tobacco sheets typically consist of homogenized tobacco fibers combined with additives such as binders, fillers, and flavor enhancers to ensure consistent texture and burn quality. Molded tobacco, however, is formed from reconstituted tobacco powder mixed with additives like plasticizers and humectants to improve flexibility and moisture retention. Both products may contain humectants like glycerin and sugars to maintain moisture, but molded tobacco often involves a higher concentration of processing additives for structural integrity.

Physical Characteristics and Appearance

Tobacco sheet features a uniform thickness and smooth texture, making it ideal for consistent rolling and cutting, whereas molded tobacco exhibits irregular shapes and varying densities due to its compressed form. The appearance of tobacco sheet is typically flat and pliable with visible leaf veins, while molded tobacco presents a more rugged and compact surface with less distinct leaf structure. Your choice between these types affects both the handling process and the visual quality of the final tobacco product.

Flavor Profile Differences

Tobacco sheets offer a consistent and mild flavor profile, often enhanced with added flavorings, making them ideal for uniform taste experiences. Molded tobacco, by contrast, provides a richer and more complex flavor due to its natural curing and pressing processes that preserve essential oils and natural tobacco nuances. Understanding these flavor profile differences helps you choose the right tobacco form to suit your desired smoking or chewing experience.

Burn Rate and Smoking Experience

Tobacco sheet provides a more consistent burn rate due to its uniform thickness, resulting in a smoother and longer-lasting smoking experience. Molded tobacco, with its compact and denser structure, burns slower but may produce a harsher smoke with more intense flavors. Your choice between tobacco sheet and molded tobacco affects both the pacing and quality of the smoke, catering to preferences for either a steady or robust burn.

Health Implications and Risks

Tobacco sheet products often contain higher levels of additives and chemicals due to processing methods, increasing exposure to harmful substances compared to molded tobacco, which is typically denser and less processed. Molded tobacco may reduce inhalation of certain toxins because of its compact structure, but both forms pose significant health risks including cancer, respiratory diseases, and cardiovascular problems. Long-term use of either tobacco sheet or molded tobacco products contributes substantially to nicotine addiction and elevated risk of chronic health conditions.

Market Trends and Consumer Preferences

Molded tobacco is gaining traction in the market due to its consistent quality and ease of use, appealing to consumers seeking uniformity and convenience in smoking products. Tobacco sheets, while traditional and favored for their artisanal appeal, face declining demand as consumer preferences shift towards modern, processed formats that offer enhanced flavor control. Your choice between these options will depend on whether you prioritize classic authenticity or innovative smoking experiences aligned with current market trends.

Choosing the Right Option: Sheet or Molded Tobacco

Choosing between tobacco sheet and molded tobacco depends on your desired smoking experience and application. Tobacco sheets offer uniformity and consistency, ideal for rolling cigarettes and cigars with a smooth burn, while molded tobacco provides a richer texture and stronger flavor, preferred by those seeking a traditional, hand-pressed feel. Understanding these differences allows you to select the best option that matches your taste preferences and smoking style.

tobacco sheet vs molded tobacco Infographic

libmatt.com

libmatt.com