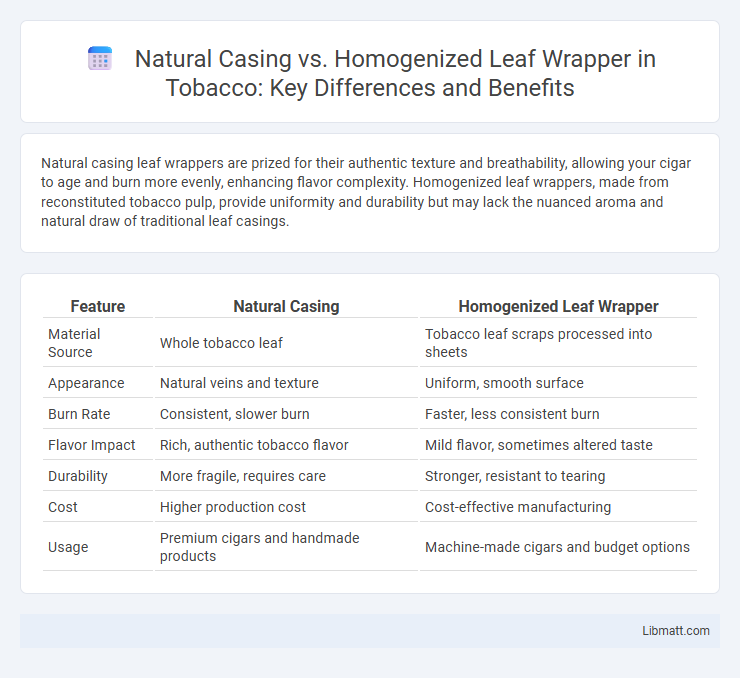

Natural casing leaf wrappers are prized for their authentic texture and breathability, allowing your cigar to age and burn more evenly, enhancing flavor complexity. Homogenized leaf wrappers, made from reconstituted tobacco pulp, provide uniformity and durability but may lack the nuanced aroma and natural draw of traditional leaf casings.

Table of Comparison

| Feature | Natural Casing | Homogenized Leaf Wrapper |

|---|---|---|

| Material Source | Whole tobacco leaf | Tobacco leaf scraps processed into sheets |

| Appearance | Natural veins and texture | Uniform, smooth surface |

| Burn Rate | Consistent, slower burn | Faster, less consistent burn |

| Flavor Impact | Rich, authentic tobacco flavor | Mild flavor, sometimes altered taste |

| Durability | More fragile, requires care | Stronger, resistant to tearing |

| Cost | Higher production cost | Cost-effective manufacturing |

| Usage | Premium cigars and handmade products | Machine-made cigars and budget options |

Introduction to Sausage Casings: Natural vs. Homogenized Leaf

Sausage casings are essential for shaping and preserving sausage products, with natural casings derived from animal intestines offering a tender texture and traditional appearance. Homogenized leaf casings, made from processed cellulose fibers, provide uniform thickness, high tensile strength, and easy peeling, ideal for mass production. Choosing between natural and homogenized leaf casings depends on desired mouthfeel, production scale, and product specifications.

What Are Natural Casings?

Natural casings are derived from the intestines of animals, typically pigs, sheep, or cows, providing a traditional and edible sausage casing that enhances flavor and texture. These casings offer breathability that allows smoke and moisture to penetrate during cooking, resulting in a distinct sausage bite and appearance. Your choice of natural casings supports authentic sausage-making practices and delivers a superior eating experience compared to homogenized alternatives.

Understanding Homogenized Leaf Wrappers

Homogenized leaf wrappers are created by blending tobacco leaves into a slurry, which is then reformed into uniform sheets, offering consistent burn and appearance compared to natural casing. Natural casing involves using whole tobacco leaves with minimal processing, retaining original leaf characteristics and potentially providing richer, more complex flavors. Homogenized leaf wrappers are engineered for uniformity and durability, making them ideal for mass-produced cigars, while natural casing appeals to aficionados seeking traditional craftsmanship and nuanced taste profiles.

Key Differences Between Natural and Homogenized Casings

Natural casings, derived from animal intestines, offer superior flavor and texture due to their porous, elastic properties that allow smoke and seasoning to penetrate, enhancing the sausage's taste profile. Homogenized leaf wrappers, made from processed cellulose or plant fibers, provide uniform thickness and consistent sizing but lack the natural breathability and complex flavor absorption of traditional casings. The key differences lie in natural casings' ability to impart authenticity and delicate bite, while homogenized casings prioritize ease of use and stable shape retention in mass production.

Texture and Flavor: Impact on Sausage Quality

Natural casing offers a traditional, tender texture that allows the sausage to expand and retain juiciness, enhancing your eating experience with a robust, authentic flavor profile. In contrast, homogenized leaf wrappers provide a uniform, consistent texture but may limit flavor complexity due to their processed nature. Choosing natural casing typically results in higher-quality sausages with superior texture and richer taste.

Production and Sourcing: How Casings Are Made

Natural casing production involves harvesting collagen-rich intestines from animals such as hogs, sheep, or cattle, followed by cleaning, salting, and drying to preserve the casing's elasticity and permeability. Homogenized leaf wrappers are created by processing tobacco leaves into a uniform pulp, which is then formed into thin sheets through a homogenization and drying process, enabling consistent texture and burn characteristics. Your choice between these casings depends on the desired production method, with natural casings offering traditional authenticity and homogenized leaf wrappers providing controlled consistency.

Cost Comparison: Natural vs. Homogenized Casings

Natural casings typically incur higher costs due to their labor-intensive processing and limited supply, making them a premium choice for artisanal sausage production. Homogenized leaf wrappers, manufactured with standardized processes and abundant raw materials, offer a more economical alternative while maintaining consistent quality. Your decision on casing should balance performance expectations with budget considerations, as natural casings provide unique texture and flavor at a higher price point.

Cooking Performance and Durability

Natural casing offers superior cooking performance by retaining moisture and enhancing heat distribution, resulting in evenly cooked flavors and a tender texture. Homogenized leaf wrappers provide consistent thickness and increased durability, reducing the risk of tearing during handling and cooking. Their uniformity ensures predictability in cooking times but may alter traditional flavor profiles compared to natural casing.

Consumer Preferences and Market Trends

Consumer preferences increasingly favor natural casing due to its authentic flavor profile and artisanal appeal, driving market growth in premium tobacco products. Homogenized leaf wrappers dominate mass-market selections, offering consistency and cost efficiency attractive to budget-conscious consumers. Understanding these trends helps you tailor product offerings to meet evolving demand in the cigar and cigarillo industry.

Choosing the Right Casing for Your Sausage

Natural casing, derived from animal intestines, offers a traditional texture and enhanced flavor that many sausage enthusiasts prefer, while homogenized leaf wrappers provide a consistent, uniform appearance and extended shelf life due to their controlled manufacturing process. Your choice between these casings depends on the desired eating experience and the sausages' intended market; natural casings tend to be more digestible and provide a better snap, whereas homogenized leaf wrappers excel in mass production and durability. Understanding these differences ensures you select the optimal casing to match your sausage's flavor profile and customer expectations.

natural casing vs homogenized leaf wrapper Infographic

libmatt.com

libmatt.com