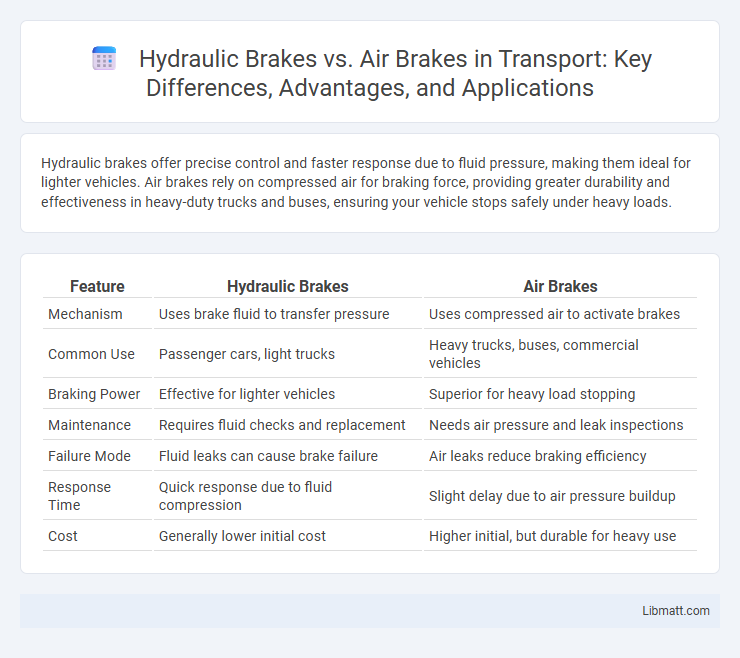

Hydraulic brakes offer precise control and faster response due to fluid pressure, making them ideal for lighter vehicles. Air brakes rely on compressed air for braking force, providing greater durability and effectiveness in heavy-duty trucks and buses, ensuring your vehicle stops safely under heavy loads.

Table of Comparison

| Feature | Hydraulic Brakes | Air Brakes |

|---|---|---|

| Mechanism | Uses brake fluid to transfer pressure | Uses compressed air to activate brakes |

| Common Use | Passenger cars, light trucks | Heavy trucks, buses, commercial vehicles |

| Braking Power | Effective for lighter vehicles | Superior for heavy load stopping |

| Maintenance | Requires fluid checks and replacement | Needs air pressure and leak inspections |

| Failure Mode | Fluid leaks can cause brake failure | Air leaks reduce braking efficiency |

| Response Time | Quick response due to fluid compression | Slight delay due to air pressure buildup |

| Cost | Generally lower initial cost | Higher initial, but durable for heavy use |

Introduction to Hydraulic and Air Brakes

Hydraulic brakes use fluid pressure to transfer force from the brake pedal to the brake pads, enabling efficient stopping power in passenger vehicles. Air brakes rely on compressed air to actuate brake chambers and are commonly used in heavy-duty trucks and buses for their durability and safety in high-load conditions. Both systems convert driver input into mechanical stopping force but differ significantly in design, maintenance, and application based on vehicle size and operational requirements.

How Hydraulic Brakes Work

Hydraulic brakes operate by using brake fluid to transfer pressure from the brake pedal to the brake pads, creating friction that slows down the vehicle. When you press the brake pedal, it activates a master cylinder that pushes the fluid through brake lines to the calipers, causing the brake pads to clamp onto the rotors. This system ensures precise and consistent braking power, making hydraulic brakes ideal for cars and small trucks.

How Air Brakes Operate

Air brakes operate by using compressed air to apply pressure to brake pads or shoes, generating the force needed to stop heavy vehicles efficiently. When you press the brake pedal, compressed air flows through the brake lines to the brake chambers, pushing a diaphragm that moves the mechanical linkage to brake the wheels. This system offers greater stopping power and reliability, especially under heavy loads, making it essential for trucks and buses.

Key Components of Each System

Hydraulic brakes consist of key components such as a master cylinder, brake fluid, calipers, and brake pads that work together to convert pedal pressure into hydraulic force for stopping power. In contrast, air brakes utilize an air compressor, reservoir tanks, brake chambers, slack adjusters, and S-cam mechanisms to create the necessary pneumatic pressure for brake application. Each system relies on distinct components tailored to their operational mechanics, with hydraulic brakes common in passenger vehicles and air brakes prevalent in heavy-duty trucks and buses.

Performance Differences: Stopping Power and Response

Hydraulic brakes provide superior stopping power and quicker response times due to their use of fluid pressure, making them ideal for lighter vehicles and precise control. Air brakes, relying on compressed air, offer consistent performance under heavy loads and are preferred in large trucks where durability and reliability matter most. Your choice between hydraulic and air brakes should consider the vehicle's weight and required braking responsiveness for optimal safety.

Maintenance Requirements and Costs

Hydraulic brakes require regular fluid checks and occasional replacement due to potential leaks and brake fluid degradation, making their maintenance relatively low-cost but essential for safety. Air brakes demand more frequent inspections of compressor systems, air lines, and tanks to prevent moisture accumulation and air leaks, resulting in higher maintenance complexity and costs. Overall, air brake systems incur greater long-term expenses due to the need for specialized components and diligent upkeep compared to hydraulic brakes.

Common Applications in Vehicles

Hydraulic brakes are commonly used in passenger cars, motorcycles, and light trucks due to their responsive stopping power and simple design. Air brakes are typically found in heavy-duty vehicles such as buses, semi-trucks, and large trailers because they provide reliable braking force for heavier loads. Your choice between hydraulic and air brakes should consider the vehicle's weight and typical operating conditions.

Safety Features and Reliability

Hydraulic brakes offer enhanced safety features such as consistent pressure distribution and quick response times, making them reliable for light to medium vehicles. Air brakes provide superior reliability for heavy-duty applications due to their fail-safe design, where a loss of air pressure engages the brakes automatically. Your choice between hydraulic and air brakes should consider the vehicle type and required safety standards for optimal performance.

Pros and Cons Comparison

Hydraulic brakes offer precise stopping power with smooth, responsive control and require less force on the brake pedal, making them ideal for passenger vehicles but are prone to fluid leaks and require regular maintenance. Air brakes provide strong braking force suitable for heavy commercial vehicles, feature fail-safe operation since air pressure loss activates brake engagement, yet they are more complex, heavier, and can experience delayed response due to air system compression. Your choice depends on vehicle type and maintenance capacity, balancing hydraulic brakes' efficiency and air brakes' reliability in demanding conditions.

Choosing the Right Brake System for Your Needs

Hydraulic brakes offer precise control and are ideal for lighter vehicles like motorcycles and passenger cars due to their efficient fluid pressure mechanism. Air brakes provide powerful stopping force and are preferred for heavy-duty trucks and buses, as they use compressed air to ensure reliable performance under high loads. Selecting the right brake system depends on vehicle weight, application, maintenance requirements, and stopping power needs.

hydraulic brakes vs air brakes Infographic

libmatt.com

libmatt.com