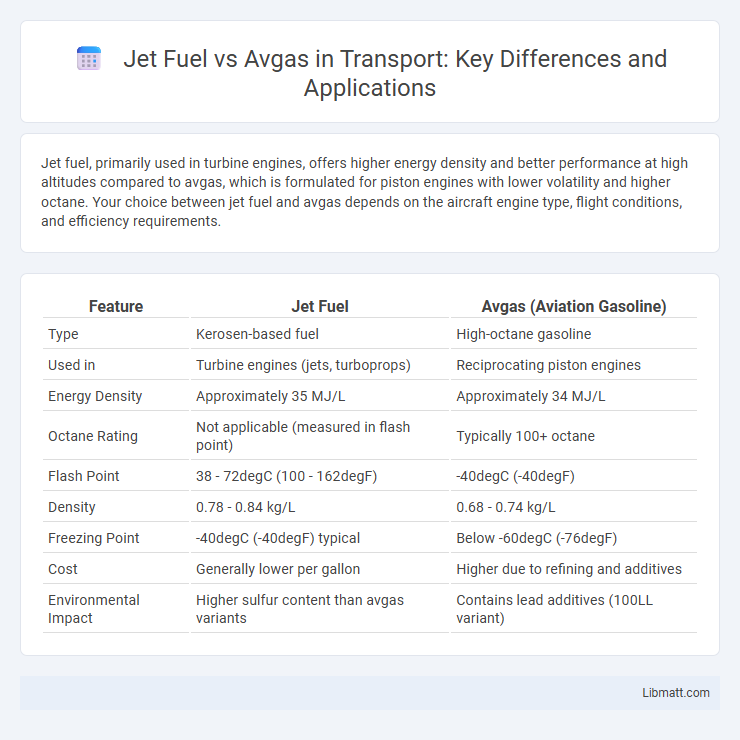

Jet fuel, primarily used in turbine engines, offers higher energy density and better performance at high altitudes compared to avgas, which is formulated for piston engines with lower volatility and higher octane. Your choice between jet fuel and avgas depends on the aircraft engine type, flight conditions, and efficiency requirements.

Table of Comparison

| Feature | Jet Fuel | Avgas (Aviation Gasoline) |

|---|---|---|

| Type | Kerosen-based fuel | High-octane gasoline |

| Used in | Turbine engines (jets, turboprops) | Reciprocating piston engines |

| Energy Density | Approximately 35 MJ/L | Approximately 34 MJ/L |

| Octane Rating | Not applicable (measured in flash point) | Typically 100+ octane |

| Flash Point | 38 - 72degC (100 - 162degF) | -40degC (-40degF) |

| Density | 0.78 - 0.84 kg/L | 0.68 - 0.74 kg/L |

| Freezing Point | -40degC (-40degF) typical | Below -60degC (-76degF) |

| Cost | Generally lower per gallon | Higher due to refining and additives |

| Environmental Impact | Higher sulfur content than avgas variants | Contains lead additives (100LL variant) |

Introduction to Jet Fuel and Avgas

Jet fuel, primarily used in turbine-engine aircraft, consists of kerosene-based fuels like Jet A and Jet A-1, known for high energy density and clean combustion. Avgas, or aviation gasoline, serves piston-engine aircraft with a high-octane formula to prevent knocking and ensure smooth engine performance. Understanding these distinct fuel types is essential for optimizing aircraft efficiency and safety in your aviation operations.

Chemical Composition Differences

Jet fuel primarily consists of kerosene-based hydrocarbons with a carbon chain length ranging from C8 to C16, whereas avgas is composed mainly of high-octane gasoline with shorter carbon chains, typically C5 to C12. Jet fuel's chemical composition includes additives for enhanced thermal stability and lubricity, while avgas contains lead-based additives like tetraethyl lead to increase octane rating and prevent engine knocking. Understanding these chemical composition differences helps you choose the appropriate fuel type to match your aircraft engine's performance and operational requirements.

Types of Aircraft Using Jet Fuel vs Avgas

Jet fuel is primarily used in turbine-engine aircraft such as commercial airliners, business jets, and helicopters, offering higher energy density and efficient combustion at high altitudes. Avgas, or aviation gasoline, powers piston-engine aircraft, including many smaller private planes and vintage aircraft, providing the necessary octane rating for spark ignition engines. Your choice between jet fuel and avgas depends on the engine type and aircraft design, with jet fuel favored for modern, high-performance turbines and avgas for traditional piston-driven planes.

Energy Density and Performance Comparison

Jet fuel, primarily used in turbine engines, offers higher energy density compared to avgas, which powers piston engines, making it more efficient for long-haul flights and higher performance needs. Avgas provides superior octane ratings essential for high-performance piston engines, but its lower energy density results in shorter range and less fuel efficiency. Understanding the energy density and performance differences between jet fuel and avgas helps you optimize fuel choice for aircraft type and mission requirements.

Storage and Handling Requirements

Jet fuel requires storage in clean, sealed tanks made of materials compatible with its kerosene-based composition, often including stainless steel or aluminum to prevent contamination and corrosion. Avgas storage demands tanks and handling equipment designed to prevent lead contamination and degradation, as avgas contains tetraethyl lead for performance enhancement. Proper handling of both fuels involves strict adherence to safety protocols to avoid spills, leaks, and ignition risks, ensuring Your aircraft's fuel quality and safety are maintained.

Cost Analysis: Jet Fuel vs Avgas

Jet fuel, primarily used in turbine engines, generally costs less per gallon than avgas, which is formulated for piston engines and subject to higher refining costs. The price disparity is influenced by production scale and regulatory standards, with avgas's lead content restrictions driving up its expense. Operators must consider these cost differences alongside fuel efficiency and engine requirements to optimize overall operational expenses.

Environmental Impact and Emissions

Jet fuel, primarily composed of kerosene, emits higher levels of carbon dioxide and particulate matter compared to avgas, contributing more significantly to greenhouse gas emissions and air pollution. Avgas, used predominantly in piston-engine aircraft, contains tetraethyl lead, which presents toxic environmental risks despite lower CO2 emissions. Advances in sustainable aviation fuels and emission reduction technologies target both fuels to minimize their ecological footprint and comply with increasingly stringent environmental regulations.

Safety Considerations and Risks

Jet fuel, primarily used in turbine engines, has a higher flash point around 38degC (100degF), making it less volatile and generally safer to handle than avgas, which has a lower flash point near -40degC (-40degF) and is more prone to ignition. Avgas contains tetraethyl lead to boost octane ratings, presenting environmental and health risks not associated with the unleaded jet fuel types. Proper storage, handling protocols, and engine compatibility are critical to mitigate fire hazards and ensure operational safety with both fuels in aviation contexts.

Availability and Global Distribution

Jet fuel is widely available globally due to its extensive use in commercial aviation and compatibility with major airports' fueling infrastructure. Avgas, primarily used for smaller piston-engine aircraft, has limited availability and is distributed mainly at regional airports, particularly in North America and Europe. The global distribution network for jet fuel benefits from large-scale refinery production and international supply chains, whereas avgas production is lower-volume and often concentrated near general aviation hubs.

Future Trends in Aviation Fuels

Jet fuel and avgas are evolving as the aviation industry pivots toward sustainability, with biofuels and synthetic alternatives gaining momentum. The development of Sustainable Aviation Fuels (SAFs) derived from renewable sources aims to reduce carbon emissions and improve energy efficiency in both turbojet and piston-engine aircraft. Your investment in aircraft operations can benefit from adopting these advanced fuels, which are projected to dominate future aviation energy markets due to regulatory pressures and environmental commitments.

jet fuel vs avgas Infographic

libmatt.com

libmatt.com