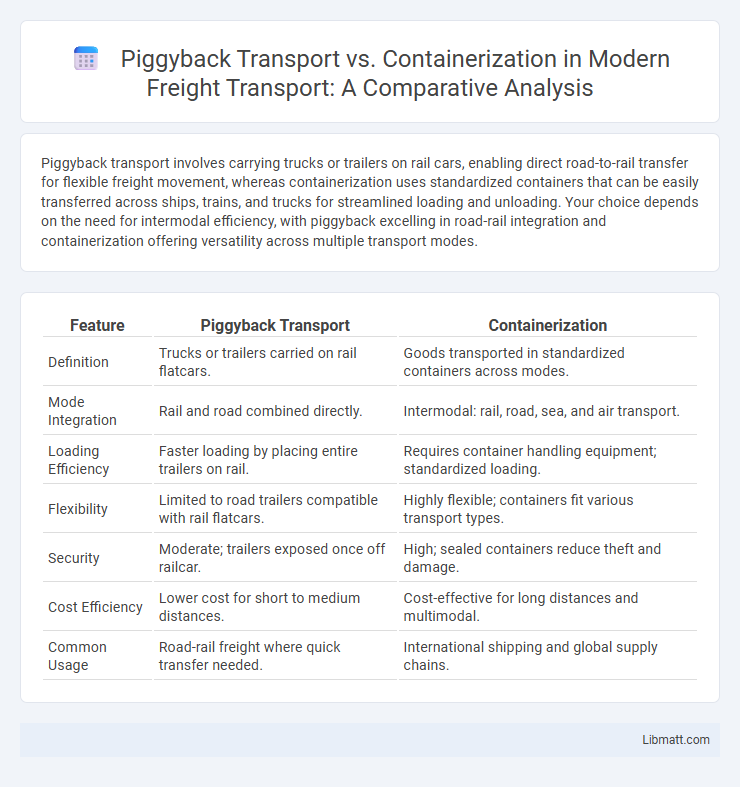

Piggyback transport involves carrying trucks or trailers on rail cars, enabling direct road-to-rail transfer for flexible freight movement, whereas containerization uses standardized containers that can be easily transferred across ships, trains, and trucks for streamlined loading and unloading. Your choice depends on the need for intermodal efficiency, with piggyback excelling in road-rail integration and containerization offering versatility across multiple transport modes.

Table of Comparison

| Feature | Piggyback Transport | Containerization |

|---|---|---|

| Definition | Trucks or trailers carried on rail flatcars. | Goods transported in standardized containers across modes. |

| Mode Integration | Rail and road combined directly. | Intermodal: rail, road, sea, and air transport. |

| Loading Efficiency | Faster loading by placing entire trailers on rail. | Requires container handling equipment; standardized loading. |

| Flexibility | Limited to road trailers compatible with rail flatcars. | Highly flexible; containers fit various transport types. |

| Security | Moderate; trailers exposed once off railcar. | High; sealed containers reduce theft and damage. |

| Cost Efficiency | Lower cost for short to medium distances. | Cost-effective for long distances and multimodal. |

| Common Usage | Road-rail freight where quick transfer needed. | International shipping and global supply chains. |

Introduction to Piggyback Transport and Containerization

Piggyback transport, also known as trailer-on-flatcar (TOFC), involves carrying truck trailers on railway flatcars, optimizing the efficiency of intermodal freight movement by combining road and rail transport. Containerization uses standardized containers to streamline cargo handling, enhance security, and improve compatibility across ships, trucks, and trains. Both methods significantly reduce loading times and transportation costs, but piggyback transport leverages existing truck trailers while containerization relies on uniform containers for global shipping ease.

Historical Development of Intermodal Freight Solutions

Piggyback transport, emerging in the early 20th century, revolutionized intermodal freight by loading truck trailers directly onto railcars, significantly enhancing efficiency and reducing road congestion. Containerization, developed in the 1950s by Malcolm McLean, introduced standardized steel containers that transformed global shipping by enabling seamless transfers between ships, trucks, and trains. Both innovations laid the foundation for modern intermodal systems, driving globalization and cost-effective logistics solutions worldwide.

Core Principles of Piggyback Transport

Piggyback transport involves the integration of road and rail systems where entire trucks or trailers are loaded onto flatbed railcars, enabling seamless movement without unloading cargo. This method optimizes efficiency by combining the flexibility of road transport with the fuel economy and capacity advantages of rail transport. Core principles include minimizing handling costs, reducing transit times, and improving supply chain reliability by leveraging intermodal transfer points.

Fundamentals of Containerization in Logistics

Containerization in logistics revolutionizes freight transport by standardizing cargo units into large, uniform containers, enabling seamless transfer across ships, trucks, and trains without repacking. This method enhances efficiency, reduces damage risk, and lowers handling costs compared to piggyback transport, which relies on carrying entire vehicles on rail flatcars. Your supply chain benefits from containerization's scalability and intermodal compatibility, ensuring faster delivery and improved cargo security.

Comparative Cost Analysis: Piggyback vs. Containerization

Piggyback transport typically incurs lower initial costs by utilizing existing rail infrastructure for truck trailers, reducing handling and terminal expenses compared to containerized freight, which requires specialized equipment and container yard operations. Containerization offers greater efficiency and security for long-distance and international shipping, potentially lowering total transportation costs through standardized handling and intermodal flexibility. You should weigh these factors against shipment volume, distance, and handling requirements to determine the most cost-effective option for your logistics needs.

Efficiency and Flexibility in Cargo Handling

Piggyback transport offers efficiency through direct rail-to-truck transfer, reducing handling times and minimizing cargo damage, making it ideal for time-sensitive shipments. Containerization enhances flexibility by standardizing cargo units that can be easily transferred across ships, trucks, and trains, optimizing storage and allowing varied cargo types. Both methods improve cargo handling efficiency, with piggyback excelling in intermodal transfers and containerization providing scalable solutions for diverse logistics needs.

Environmental Impact and Sustainability Considerations

Piggyback transport reduces environmental impact by combining truck and rail freight, significantly lowering fuel consumption and greenhouse gas emissions compared to long-haul trucking alone. Containerization enhances sustainability through standardized, reusable containers that streamline intermodal transfers, reducing transit times and minimizing cargo handling damage. Both methods contribute to greener logistics by optimizing transport efficiency and supporting the global shift toward sustainable supply chains.

Security and Cargo Protection: A Comparative Review

Piggyback transport offers moderate security with cargo exposed to external elements during transfer between rail and road, increasing risk of damage or theft. Containerization provides superior cargo protection through fully enclosed, standardized containers that shield goods from weather, theft, and handling damage. Your choice between these methods can significantly impact the integrity and security of transported goods, with containerization generally preferred for high-value or sensitive cargo.

Industry Applications and Use Cases

Piggyback transport is widely used in the automotive industry for moving finished vehicles on rail flatcars, providing cost-effective, efficient intermodal solutions between manufacturing plants and distribution centers. Containerization dominates global trade, enabling seamless shipment of diverse goods such as electronics, textiles, and machinery across ships, trucks, and trains, optimizing cargo security and handling. Your choice between piggyback transport and containerization depends on cargo type, logistics infrastructure, and the need for flexibility in multimodal supply chains.

Future Trends in Intermodal Transport Systems

Piggyback transport, which involves carrying truck trailers on rail flatcars, continues to evolve with innovations in automated handling and infrastructure upgrades, boosting efficiency and reducing transit times. Containerization, dominating intermodal freight, is advancing through smart container technologies integrating IoT sensors for real-time tracking, condition monitoring, and enhanced supply chain visibility. Your logistics operations can benefit from these future trends as intermodal systems increasingly prioritize sustainability, digitization, and seamless modal transitions to meet growing global trade demands.

piggyback transport vs containerization Infographic

libmatt.com

libmatt.com