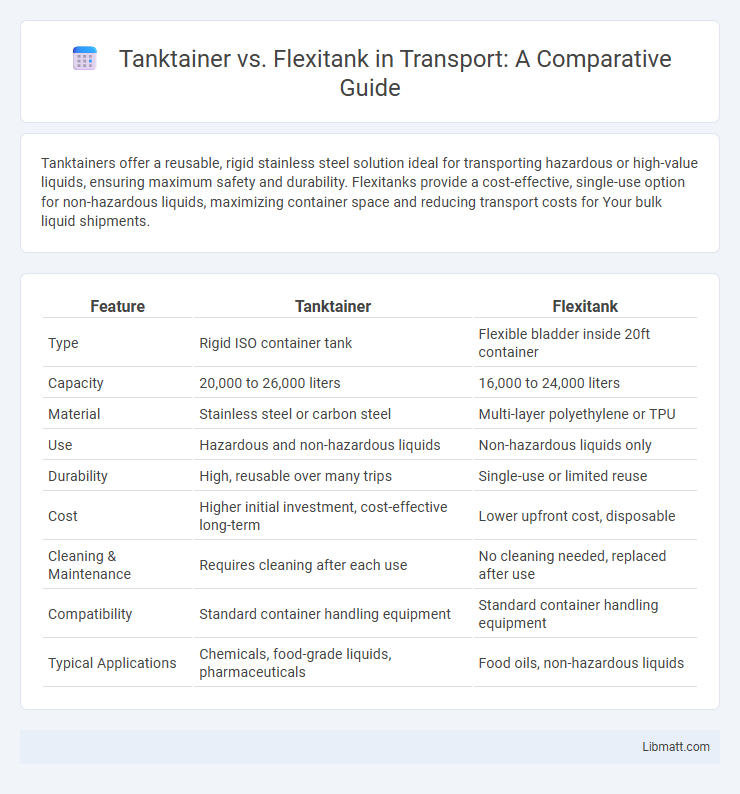

Tanktainers offer a reusable, rigid stainless steel solution ideal for transporting hazardous or high-value liquids, ensuring maximum safety and durability. Flexitanks provide a cost-effective, single-use option for non-hazardous liquids, maximizing container space and reducing transport costs for Your bulk liquid shipments.

Table of Comparison

| Feature | Tanktainer | Flexitank |

|---|---|---|

| Type | Rigid ISO container tank | Flexible bladder inside 20ft container |

| Capacity | 20,000 to 26,000 liters | 16,000 to 24,000 liters |

| Material | Stainless steel or carbon steel | Multi-layer polyethylene or TPU |

| Use | Hazardous and non-hazardous liquids | Non-hazardous liquids only |

| Durability | High, reusable over many trips | Single-use or limited reuse |

| Cost | Higher initial investment, cost-effective long-term | Lower upfront cost, disposable |

| Cleaning & Maintenance | Requires cleaning after each use | No cleaning needed, replaced after use |

| Compatibility | Standard container handling equipment | Standard container handling equipment |

| Typical Applications | Chemicals, food-grade liquids, pharmaceuticals | Food oils, non-hazardous liquids |

Introduction to Tanktainer and Flexitank

Tanktainers are ISO-certified, reusable containers designed for transporting bulk liquids like chemicals, food-grade oils, and hazardous materials with secure, rigid steel construction. Flexitanks are large, flexible bladders installed inside standard 20-foot containers, ideal for shipping non-hazardous liquids such as wine, vegetable oils, and juices in one-way shipments. Both solutions optimize liquid cargo transport but differ in reusability, cost, and suitability based on cargo type and shipment frequency.

Understanding Tanktainer: Features and Benefits

Tanktainers are ISO-standardized containers designed for the safe transport of bulk liquids, featuring a stainless steel inner tank with robust outer framing for enhanced durability. Their reusable structure ensures minimal contamination risk, optimal hygiene, and suitability for hazardous materials, making them ideal for long-term, high-value liquid shipments. Tanktainers support temperature control options and precise volume measurements, providing reliable logistics solutions across chemical, food-grade, and pharmaceutical industries.

What is a Flexitank? Key Advantages

A Flexitank is a large, flexible bladder designed to fit inside a standard shipping container, allowing non-hazardous liquids to be transported efficiently in bulk. Key advantages include cost-effectiveness, increased shipping volume compared to drums, and easy installation and disposal, making it ideal for industries such as food, chemicals, and agriculture. You benefit from reduced packaging waste and streamlined logistics with the adaptability of Flexitanks.

Cost Comparison: Tanktainer vs Flexitank

Flexitanks generally offer a more cost-effective solution for transporting bulk liquids compared to tanktainers due to lower initial investment and reduced handling expenses. Tanktainers involve higher upfront costs, including specialized equipment and maintenance, but provide reusable and durable containment suitable for long-term operations. Evaluating total cost of ownership depends on shipment frequency, volume, and logistics, with flexitanks favored for single-use, high-volume shipments and tanktainers preferred for recurring liquid transportation needs.

Capacity and Load Efficiency

Flexitanks offer a higher liquid cargo capacity, typically up to 24,000 liters, maximizing container space compared to tanktainers, which usually hold around 20,000 liters. Your choice impacts load efficiency, as flexitanks utilize nearly the entire container volume without requiring additional handling equipment, while tanktainers are rigid and may reduce available space due to their structural design. This capacity difference means flexitanks often provide better cargo volume optimization for bulk liquid transport within standard 20-foot containers.

Safety and Risk Factors

Tanktainers offer superior safety with rigid steel structures designed to withstand high pressure and rough handling, minimizing the risk of leaks and contamination. Flexitanks, made from multi-layered polyethylene, pose higher risk of punctures and spills, especially when transporting hazardous liquids or under extreme temperature variations. Strict adherence to packaging standards and secure installation are critical to mitigating risk in flexitank use compared to the inherently robust tanktainer system.

Environmental Impact and Sustainability

Tanktainers offer a reusable solution that significantly reduces single-use waste and minimizes environmental impact through durable construction and efficient cleaning processes. Flexitanks, while disposable, are made of recyclable materials but contribute to more waste due to single-use design and shorter lifecycle. Your choice between tanktainers and flexitanks should consider sustainability goals, with tanktainers generally providing a greener option for long-term liquid cargo transport.

Suitable Cargo Types and Applications

Tanktainers are ideal for transporting hazardous liquids, chemicals, and industrial fluids that require rigid, secure containment and compliance with safety regulations. Flexitanks excel in shipping non-hazardous bulk liquids like edible oils, wine, and juices, offering cost-effective and flexible solutions for one-time use within standard 20-foot containers. Your choice between tanktainer and flexitank depends on the cargo's nature, safety requirements, and shipment volume.

Handling, Installation, and Logistics

Tanktainers offer robust handling with rigid steel frames, ensuring secure stacking and easy forklift or crane operations, while flexitanks require careful handling due to their flexible material and potential puncture risks. Installation of tanktainers is straightforward, as they arrive pre-installed and ready for use, whereas flexitanks need to be installed inside standard containers, demanding trained personnel to ensure proper fit and sealing. Your choice impacts logistics efficiency; tanktainers simplify transport with integrated structures ideal for repeated use, whereas flexitanks provide weight and cost advantages for single-use bulk liquid shipments but require more careful handling and disposal considerations.

Choosing the Best Solution: Tanktainer or Flexitank

Selecting between a tanktainer and a flexitank depends on the nature of your liquid cargo and shipment requirements. Tanktainers offer reusable, robust containment ideal for high-value or hazardous liquids, ensuring maximum protection and compliance with safety regulations. Flexitanks provide cost-effective, single-use solutions for non-hazardous bulk liquids, optimizing space in standard containers and reducing overall transportation costs.

tanktainer vs flexitank Infographic

libmatt.com

libmatt.com