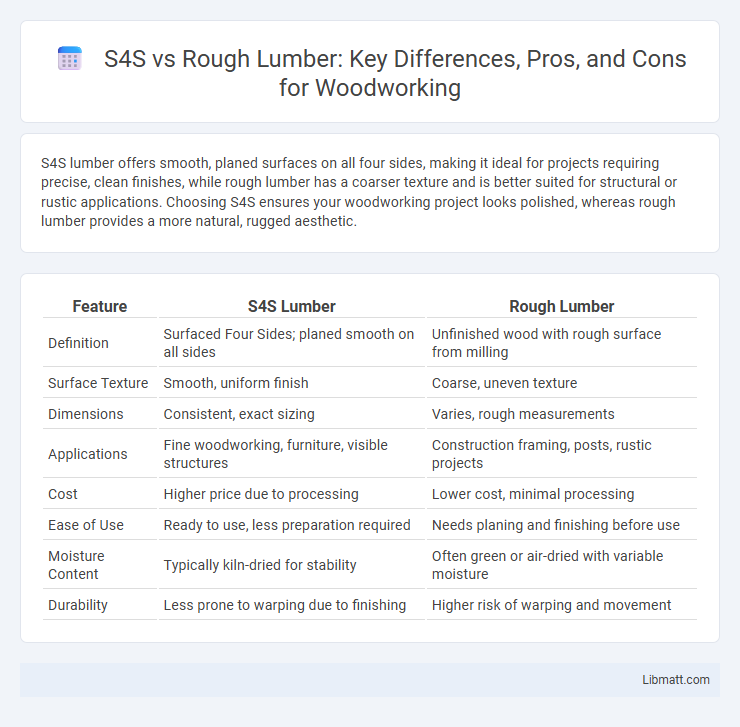

S4S lumber offers smooth, planed surfaces on all four sides, making it ideal for projects requiring precise, clean finishes, while rough lumber has a coarser texture and is better suited for structural or rustic applications. Choosing S4S ensures your woodworking project looks polished, whereas rough lumber provides a more natural, rugged aesthetic.

Table of Comparison

| Feature | S4S Lumber | Rough Lumber |

|---|---|---|

| Definition | Surfaced Four Sides; planed smooth on all sides | Unfinished wood with rough surface from milling |

| Surface Texture | Smooth, uniform finish | Coarse, uneven texture |

| Dimensions | Consistent, exact sizing | Varies, rough measurements |

| Applications | Fine woodworking, furniture, visible structures | Construction framing, posts, rustic projects |

| Cost | Higher price due to processing | Lower cost, minimal processing |

| Ease of Use | Ready to use, less preparation required | Needs planing and finishing before use |

| Moisture Content | Typically kiln-dried for stability | Often green or air-dried with variable moisture |

| Durability | Less prone to warping due to finishing | Higher risk of warping and movement |

Introduction to S4S and Rough Lumber

S4S (Surfaced Four Sides) lumber is precisely planed on all four sides, providing a smooth and uniform finish ideal for cabinetry, furniture, and trim work. Rough lumber, in contrast, is typically unplaned, retaining its natural, rough texture directly from the sawmill, making it preferred for rustic designs or projects requiring custom milling. The choice between S4S and rough lumber depends on the need for finished aesthetics versus versatility and cost-effectiveness in woodworking projects.

Understanding S4S Lumber: Definition and Uses

S4S lumber, or surfaced four sides lumber, is wood that has been planed on all four sides to achieve smooth, uniform surfaces, making it ideal for precise construction and fine woodworking projects. Its consistent dimensions and smooth finish reduce sanding and preparation time, enhancing efficiency in building furniture, cabinetry, and trim work. When choosing between S4S and rough lumber, your decision should consider the need for ready-to-use material versus customization and cost savings.

What is Rough Lumber? An Overview

Rough lumber refers to wood that has been sawed but remains unplaned, retaining a coarse surface with natural textures and irregularities. It is commonly used for construction projects where precise dimensions are less critical, offering strength and durability without the smooth finish of surfaced lumber. Your choice between rough lumber and surfaced four sides (S4S) depends on the need for exact measurements or a refined appearance in your woodworking or building project.

Key Differences Between S4S and Rough Lumber

S4S lumber is surfaced on all four sides, providing smooth, uniform dimensions that enhance ease of use in cabinetry, furniture, and finish carpentry. Rough lumber, in contrast, retains its natural texture and uneven surfaces, requiring additional planing or sanding for precise applications. Your choice depends on project requirements: S4S offers ready-to-use precision, while rough lumber suits projects benefiting from rustic aesthetics or custom finishing.

Pros and Cons of S4S Lumber

S4S (Sawn Four Sides) lumber offers smooth, uniform surfaces on all four sides, making it ideal for precise woodworking and furniture projects where clean finishes are essential. However, S4S lumber costs more than rough lumber due to the extra processing involved, and its smooth surfaces can hide minor defects that rough lumber's texture reveals. Your choice between S4S and rough lumber depends on the need for immediate usability versus budget and flexibility in custom shaping.

Advantages and Disadvantages of Rough Lumber

Rough lumber offers a natural, rustic appearance and typically costs less than S4S (surfaced four sides) lumber, making it ideal for projects where texture and authenticity are prioritized. However, rough lumber requires additional work, such as planing and sanding, to achieve smooth, precise dimensions, which can increase labor and time on your woodworking project. Its uneven surfaces and potential for warping also pose challenges compared to the uniform finish and consistent sizing of S4S lumber.

Cost Comparison: S4S vs Rough Lumber

Surface Sawn S4S (Surfaced Four Sides) lumber generally costs more than rough lumber due to the additional processing of planing and smoothing all four sides, which enhances the wood's appearance and precision dimensions. Rough lumber, being unprocessed and rough-cut, is typically less expensive but requires more labor and time for finishing to achieve the same quality as S4S. When budgeting for projects, the higher upfront cost of S4S can be offset by reduced labor and material waste during construction, making it cost-effective despite the price difference.

Applications and Best Uses for Each Type

S4S lumber offers smooth, consistent surfaces making it ideal for fine woodworking, cabinetry, and furniture where precision and finished appearance are crucial. Rough lumber is preferred for construction, framing, and projects requiring structural strength where appearance is less important and customization is needed. Your choice depends on whether you need ready-to-use finished wood or versatile material for further shaping and heavy-duty use.

Considerations for Woodworking Projects

S4S wood offers smooth, planed surfaces on all sides, minimizing sanding time and providing precise, consistent dimensions crucial for fine woodworking projects. Rough lumber retains its natural texture, allowing for greater flexibility in thickness adjustments and cost savings but requires more preparation, such as jointing and planing. Your choice depends on the project's precision needs, surface finish preferences, and budget constraints, with S4S ideal for detailed joinery and rough lumber suited for custom milling or rustic designs.

How to Choose Between S4S and Rough Lumber

Choosing between S4S and rough lumber depends on your project's requirements for precision and finish quality. S4S (Surfaced Four Sides) lumber offers smooth, uniform surfaces ideal for furniture or cabinetry, while rough lumber provides a more rustic look and greater thickness options. Consider your need for dimensional accuracy and surface finish to determine which lumber best suits your woodworking or construction goals.

S4S vs rough lumber Infographic

libmatt.com

libmatt.com