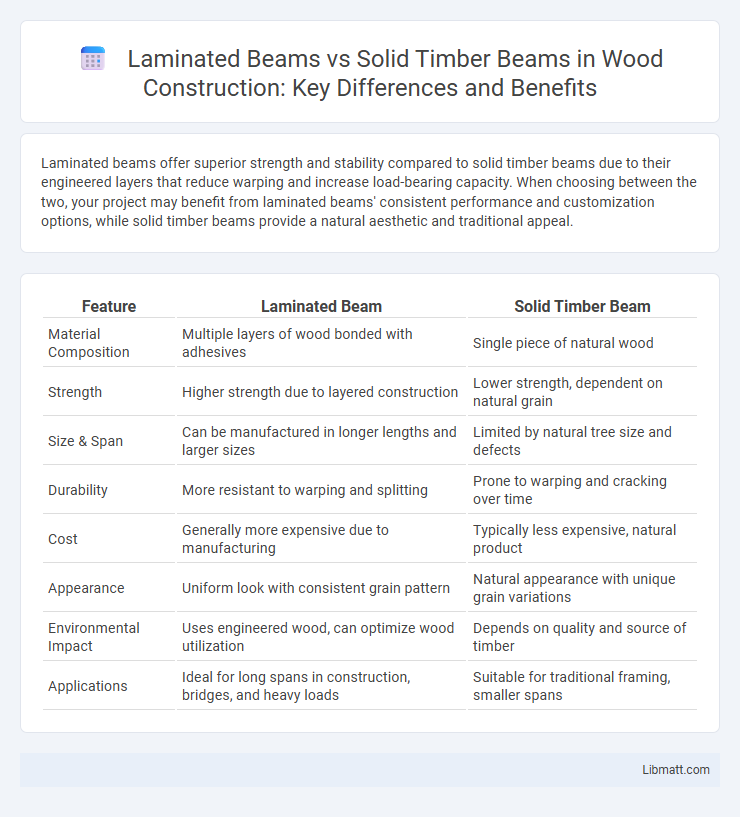

Laminated beams offer superior strength and stability compared to solid timber beams due to their engineered layers that reduce warping and increase load-bearing capacity. When choosing between the two, your project may benefit from laminated beams' consistent performance and customization options, while solid timber beams provide a natural aesthetic and traditional appeal.

Table of Comparison

| Feature | Laminated Beam | Solid Timber Beam |

|---|---|---|

| Material Composition | Multiple layers of wood bonded with adhesives | Single piece of natural wood |

| Strength | Higher strength due to layered construction | Lower strength, dependent on natural grain |

| Size & Span | Can be manufactured in longer lengths and larger sizes | Limited by natural tree size and defects |

| Durability | More resistant to warping and splitting | Prone to warping and cracking over time |

| Cost | Generally more expensive due to manufacturing | Typically less expensive, natural product |

| Appearance | Uniform look with consistent grain pattern | Natural appearance with unique grain variations |

| Environmental Impact | Uses engineered wood, can optimize wood utilization | Depends on quality and source of timber |

| Applications | Ideal for long spans in construction, bridges, and heavy loads | Suitable for traditional framing, smaller spans |

Introduction to Laminated and Solid Timber Beams

Laminated beams consist of multiple layers of wood glued together, offering enhanced strength, durability, and resistance to warping compared to solid timber beams, which are made from a single, continuous piece of wood. The lamination process allows for larger spans and customized shapes, making laminated beams ideal for architectural and structural applications requiring flexibility and load-bearing capacity. Solid timber beams, while simpler and often more cost-effective, may be more susceptible to natural defects such as knots and splits, limiting their size and performance in heavy-duty construction.

Material Composition and Manufacturing Process

Laminated beams consist of multiple layers of wood glued together, providing enhanced strength and stability compared to solid timber beams, which are cut from a single piece of wood. The manufacturing process of laminated beams involves bonding thin wood veneers with durable adhesives under controlled conditions, reducing defects such as knots and increasing uniformity. Your choice between laminated and solid timber beams should consider how these material compositions impact load-bearing capacity and long-term performance in construction projects.

Structural Strength and Load-Bearing Capacity

Laminated beams exhibit superior structural strength and load-bearing capacity compared to solid timber beams due to their engineered composition, which effectively distributes stress across multiple layers of wood. The lamination process minimizes natural defects such as knots or splits, enhancing dimensional stability and resistance to bending and warping under heavy loads. Consequently, laminated beams are often preferred in construction requiring high-performance support, enabling longer spans and greater load endurance than traditional solid timber beams.

Durability and Resistance to Environmental Factors

Laminated beams offer superior durability and enhanced resistance to environmental factors due to their engineered layers, which reduce susceptibility to warping, splitting, and moisture damage compared to solid timber beams. The adhesive used in laminated beams provides added protection against fungal decay and insect infestation, extending the lifespan of the structure. Solid timber beams, while strong, are more prone to shrinkage, swelling, and surface degradation when exposed to fluctuating humidity and temperature conditions.

Design Flexibility and Size Limitations

Laminated beams offer greater design flexibility compared to solid timber beams due to their ability to be fabricated in longer lengths and varied shapes, accommodating architectural demands for curved or irregular forms. Solid timber beams are limited by the natural size of available timber, restricting their maximum length and cross-sectional dimensions, which can constrain structural applications in large-span projects. Engineered laminated beams also provide consistent strength and stiffness by minimizing defects found in solid timber, making them ideal for tailored design specifications and structural performance.

Cost Comparison and Economic Considerations

Laminated beams often present a more cost-effective option compared to solid timber beams due to their efficient use of smaller pieces of wood bonded together, reducing waste and allowing for longer spans without additional support. While solid timber beams provide natural aesthetics, laminated beams offer better strength-to-weight ratios and greater design flexibility, which can lower labor and material costs in complex projects. Your choice between laminated and solid timber beams should factor in initial material costs, long-term durability, and potential savings from reduced maintenance and transportation expenses.

Sustainability and Environmental Impact

Laminated beams, often made from multiple layers of sustainably sourced wood, offer enhanced resource efficiency by utilizing smaller trees and reducing waste compared to solid timber beams. Their engineered design improves structural strength and stability, allowing for longer spans and lighter materials, which reduce transportation emissions and construction footprint. Solid timber beams, while natural and biodegradable, generally require larger, older trees, leading to greater deforestation risks and less efficient use of forest resources.

Installation and Handling Differences

Laminated beams are lighter and easier to handle on site compared to solid timber beams, allowing for quicker installation and reduced labor costs. Their engineered structure provides greater dimensional stability, minimizing warping and splitting during handling and placement. You can benefit from laminated beams' uniformity, which simplifies alignment and fastening processes, enhancing overall construction efficiency.

Common Applications in Construction

Laminated beams are commonly used in large-span structures such as bridges, commercial buildings, and residential roofs due to their enhanced strength and stability compared to solid timber beams. Solid timber beams often find applications in traditional residential framing, flooring joists, and interior architectural features where natural aesthetics and simpler installation are priorities. Your choice between laminated and solid timber beams should consider the specific load requirements and design preferences of your construction project.

Maintenance Requirements and Longevity

Laminated beams offer enhanced durability and resistance to warping, requiring less frequent maintenance compared to solid timber beams, which are more susceptible to cracking and moisture damage. Proper sealing and regular inspections are crucial for both types, but laminated beams typically maintain structural integrity longer due to engineered layers. Your choice of beam impacts long-term upkeep costs and the lifespan of the structure, with laminated options generally providing superior longevity under similar conditions.

Laminated beam vs solid timber beam Infographic

libmatt.com

libmatt.com