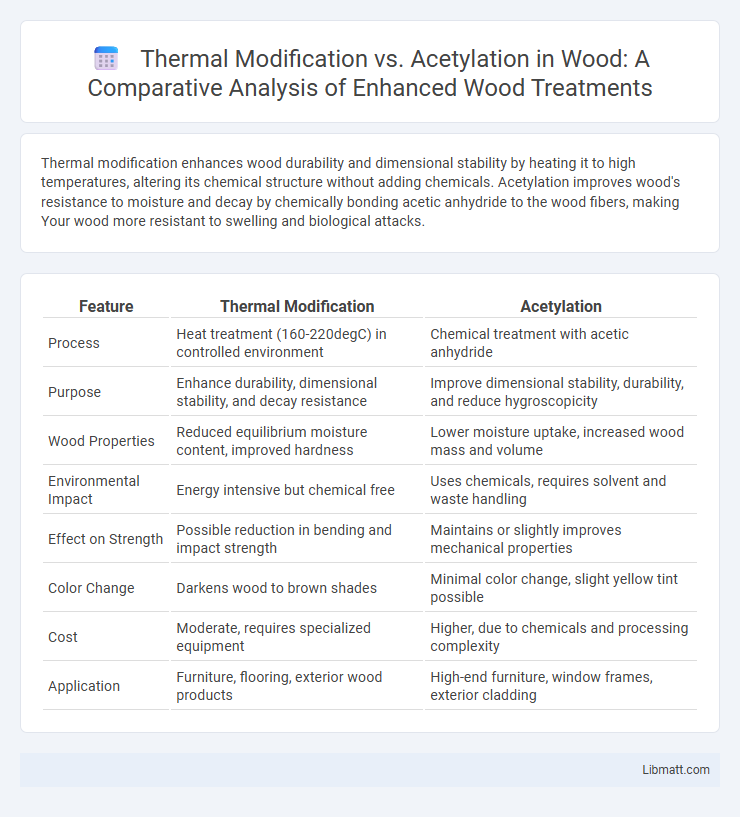

Thermal modification enhances wood durability and dimensional stability by heating it to high temperatures, altering its chemical structure without adding chemicals. Acetylation improves wood's resistance to moisture and decay by chemically bonding acetic anhydride to the wood fibers, making Your wood more resistant to swelling and biological attacks.

Table of Comparison

| Feature | Thermal Modification | Acetylation |

|---|---|---|

| Process | Heat treatment (160-220degC) in controlled environment | Chemical treatment with acetic anhydride |

| Purpose | Enhance durability, dimensional stability, and decay resistance | Improve dimensional stability, durability, and reduce hygroscopicity |

| Wood Properties | Reduced equilibrium moisture content, improved hardness | Lower moisture uptake, increased wood mass and volume |

| Environmental Impact | Energy intensive but chemical free | Uses chemicals, requires solvent and waste handling |

| Effect on Strength | Possible reduction in bending and impact strength | Maintains or slightly improves mechanical properties |

| Color Change | Darkens wood to brown shades | Minimal color change, slight yellow tint possible |

| Cost | Moderate, requires specialized equipment | Higher, due to chemicals and processing complexity |

| Application | Furniture, flooring, exterior wood products | High-end furniture, window frames, exterior cladding |

Introduction to Wood Modification Techniques

Thermal modification and acetylation are advanced wood modification techniques that enhance durability and dimensional stability by altering the wood's chemical properties. Thermal modification uses high temperatures to reduce hygroscopicity and improve resistance to decay, while acetylation introduces acetic anhydride to chemically bond with wood cell molecules, significantly reducing moisture absorption. Both methods extend the lifespan of wood products, making them more sustainable alternatives to untreated timber in construction and outdoor applications.

Overview of Thermal Modification

Thermal modification involves the thermal treatment of wood at temperatures typically between 160degC and 260degC in an oxygen-free environment to improve durability and dimensional stability by altering the chemical structure of hemicellulose, cellulose, and lignin. This process reduces wood's hygroscopicity, leading to enhanced resistance to decay, reduced water absorption, and improved overall longevity without the use of toxic chemicals. Thermal modification is widely applied in hardwoods and softwoods, making it a sustainable alternative to traditional wood preservatives for outdoor and structural applications.

What is Acetylation?

Acetylation is a chemical process that enhances wood durability and dimensional stability by introducing acetyl groups into the cellulose structure, effectively reducing its ability to absorb moisture. Unlike thermal modification, which uses heat to alter wood properties, acetylation modifies the wood at a molecular level, resulting in increased resistance to decay and reduced swelling. Your wood products treated with acetylation benefit from improved longevity and performance in outdoor applications without compromising strength.

Key Differences: Thermal Modification vs Acetylation

Thermal modification alters wood properties through controlled heat treatment, enhancing durability and dimensional stability by degrading hemicelluloses, while acetylation chemically modifies wood by substituting hydroxyl groups with acetyl groups, improving moisture resistance and decay durability. Thermal modification typically results in a darker color and slight reduction in mechanical strength, whereas acetylation maintains original wood color and often improves strength. The key difference lies in the process--thermal modification is a physical heat treatment, and acetylation is a chemical reaction--leading to distinct effects on wood performance and environmental impact.

Impact on Wood Durability

Thermal modification improves wood durability by altering its chemical structure, reducing hygroscopicity, and increasing resistance to decay and insect attacks, with treatment temperatures typically ranging from 160degC to 220degC. Acetylation enhances wood durability by chemically reacting wood cell wall hydroxyl groups with acetic anhydride, resulting in reduced moisture absorption and increased resistance to fungal decay, often extending service life by several decades. Both methods significantly improve wood durability, but acetylation generally offers superior long-term biological resistance under diverse environmental conditions.

Effects on Moisture Resistance

Thermal modification reduces wood's hygroscopicity by altering the cell wall structure, significantly improving moisture resistance and dimensional stability. Acetylation enhances moisture resistance by chemically bonding acetyl groups to wood fibers, thereby reducing hydroxyl groups that attract water, resulting in superior moisture barrier properties. Both processes increase wood durability, but acetylation typically provides longer-lasting and more effective moisture resistance than thermal modification.

Environmental Considerations

Thermal modification and acetylation both enhance wood durability while minimizing environmental impact compared to traditional chemical treatments. Thermal modification uses heat to alter the wood's cellular structure without toxic chemicals, resulting in lower emissions and improved biodegradability. Acetylation involves reacting wood with acetic anhydride, increasing dimensional stability and decay resistance while producing non-toxic byproducts that have minimal ecological footprint.

Cost Comparison

Thermal modification generally incurs lower upfront costs due to simpler processing equipment and energy requirements compared to acetylation, which involves the use of chemical reagents such as acetic anhydride that increase material and handling expenses. Acetylation offers longer-lasting wood durability and improved dimensional stability, potentially reducing lifecycle costs despite higher initial investment. For large-scale industrial applications, thermal modification may be more cost-effective, while acetylation provides superior performance benefits justifying its premium price in specialized uses.

Common Applications

Thermal modification is commonly used to enhance the durability and stability of softwoods for outdoor decking, cladding, and garden furniture by reducing moisture absorption and improving resistance to decay. Acetylation primarily benefits hardwoods, making them ideal for applications requiring dimensional stability and resistance to biological damage, such as window frames, flooring, and high-end furniture. Your choice between these treatments depends on the specific wood species and the performance requirements of your project.

Choosing the Right Method for Your Project

Thermal modification enhances wood's dimensional stability and resistance to decay by heating it to high temperatures, making it ideal for outdoor applications where moisture exposure is prevalent. Acetylation chemically alters wood fibers through the addition of acetic anhydride, significantly improving durability and resistance to biological degradation without compromising strength, suitable for structural and high-performance uses. Selecting between thermal modification and acetylation depends on factors like desired durability, environmental impact, project budget, and wood species, ensuring optimal performance and longevity tailored to specific project requirements.

Thermal modification vs acetylation Infographic

libmatt.com

libmatt.com