Sawn lumber is cut directly from logs into standard-sized boards, providing consistency for general use, while re-sawn lumber involves slicing existing boards into thinner pieces, optimizing material utilization for specific projects. Your choice between sawn and re-sawn lumber affects both the wood's thickness and the final appearance of your woodworking project.

Table of Comparison

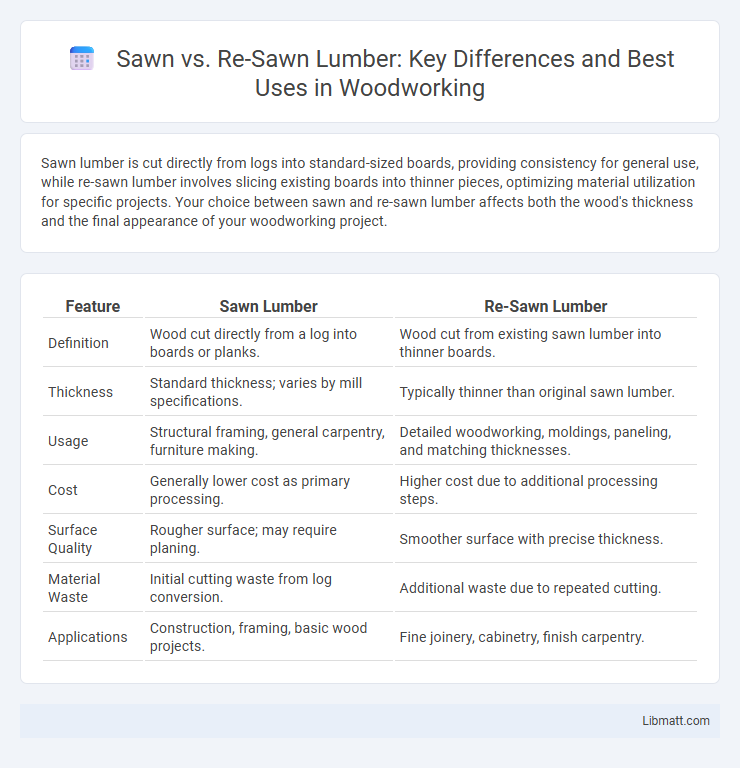

| Feature | Sawn Lumber | Re-Sawn Lumber |

|---|---|---|

| Definition | Wood cut directly from a log into boards or planks. | Wood cut from existing sawn lumber into thinner boards. |

| Thickness | Standard thickness; varies by mill specifications. | Typically thinner than original sawn lumber. |

| Usage | Structural framing, general carpentry, furniture making. | Detailed woodworking, moldings, paneling, and matching thicknesses. |

| Cost | Generally lower cost as primary processing. | Higher cost due to additional processing steps. |

| Surface Quality | Rougher surface; may require planing. | Smoother surface with precise thickness. |

| Material Waste | Initial cutting waste from log conversion. | Additional waste due to repeated cutting. |

| Applications | Construction, framing, basic wood projects. | Fine joinery, cabinetry, finish carpentry. |

Introduction to Sawn vs Re-Sawn Lumber

Sawn lumber refers to wood that has been cut directly from a log into boards with standard thickness and width, offering structural stability and uniformity. Re-sawn lumber involves slicing thicker boards into thinner pieces, maximizing material use and revealing unique grain patterns ideal for finishing and aesthetic applications. Understanding the differences is crucial for selecting lumber in construction, woodworking, and design projects.

Defining Sawn Lumber: Basics and Characteristics

Sawn lumber refers to wood that has been cut directly from logs into boards, primarily using a sawmill, resulting in various sizes and thicknesses suited for construction and woodworking projects. Its characteristics include visible grain patterns, natural moisture content, and standard dimensional measurements like thickness, width, and length, typically expressed in nominal sizes such as 2x4 or 1x6. This type of lumber provides fundamental structural integrity and aesthetic appeal, commonly used in framing, flooring, and furniture making.

What is Re-Sawn Lumber? Key Features Explained

Re-sawn lumber is wood that has been cut a second time, typically turning thicker boards into thinner planks with different grain patterns and increased surface area. This process enhances the lumber's visual appeal by exposing unique grain features and allows you to maximize wood utilization from a single board. Key features include its cost-effectiveness, versatility for various woodworking projects, and the ability to produce consistent, dimensionally stable boards ideal for cabinetry, flooring, and paneling.

Milling Processes: Sawn vs Re-Sawn Comparison

Sawn lumber is produced directly from logs through primary milling, where large sections are cut into boards of various thicknesses, optimizing yield and structural integrity. Re-sawn lumber involves cutting previously milled boards into thinner slices, enhancing aesthetic appeal by exposing new grain patterns but often reducing overall strength. Your choice between sawn and re-sawn lumber depends on the desired balance between thickness, appearance, and application in woodworking projects.

Grain Patterns and Surface Texture Differences

Sawn lumber typically exhibits prominent, varied grain patterns with a rougher surface texture due to the standard milling process, resulting in visible saw marks and a natural, rustic appearance. Re-sawn lumber, cut by slicing thick boards into thinner pieces, reveals more uniform grain patterns and smoother surfaces, enhancing aesthetics for fine woodworking and making it ideal for decorative applications. The re-sawing process emphasizes the wood's natural lines while minimizing surface imperfections compared to traditional sawn lumber.

Cost Considerations: Which Option is More Affordable?

Sawn lumber typically offers a more affordable option compared to re-sawn lumber due to lower processing costs and reduced labor requirements. Re-sawn lumber involves extra milling steps to create thinner boards, increasing production expenses and therefore raising the price per board foot. For budget-conscious woodworking projects, choosing standard sawn lumber often provides better cost efficiency without sacrificing material quality.

Common Uses for Sawn and Re-Sawn Lumber

Sawn lumber is commonly used in construction framing, furniture making, and general woodworking projects due to its structural integrity and consistent thickness. Re-sawn lumber, cut into thinner slabs from thicker boards, is ideal for creating veneers, paneling, and intricate millwork, offering versatility in design without sacrificing wood grain quality. Your choice between sawn and re-sawn lumber depends on the project's requirements for thickness, finish, and aesthetic detail.

Durability and Structural Integrity Analysis

Sawn lumber, cut directly from logs using standard methods, typically exhibits consistent durability and structural integrity due to uniform grain orientation and reduced defects. Re-sawn lumber, produced by slicing thicker sawn boards into thinner pieces, may experience slight reductions in strength and increased susceptibility to warping or splitting because of altered grain patterns and additional stress from secondary cuts. Proper kiln drying and treatment can mitigate these issues, but original sawn lumber generally provides superior load-bearing capacity and longevity in structural applications.

Environmental Impact and Sustainability Factors

Sawn lumber typically results in higher waste due to the standard milling process, whereas re-sawn lumber maximizes material use by reslicing thick boards into smaller, more dimensionally stable pieces, reducing wood waste and promoting sustainability. Re-sawn lumber often comes from reclaimed or older stock, minimizing the demand for newly harvested trees and lowering its environmental footprint compared to freshly sawn timber. Choosing re-sawn lumber for your projects supports eco-friendly building practices by conserving natural resources and reducing deforestation.

Choosing the Right Lumber for Your Project

Sawn lumber, cut directly from logs, offers consistent thickness and structural integrity ideal for framing and load-bearing applications, while re-sawn lumber, sliced from thicker planks, provides thinner boards with unique grain patterns suited for fine woodworking and decorative finishes. Selecting the right lumber depends on project requirements such as durability, appearance, and thickness precision; re-sawn lumber allows for custom thickness but may sacrifice some structural strength compared to sawn lumber. Prioritize sawn lumber for construction and re-sawn for aesthetic applications to optimize both function and design in your woodworking project.

Sawn vs re-sawn lumber Infographic

libmatt.com

libmatt.com