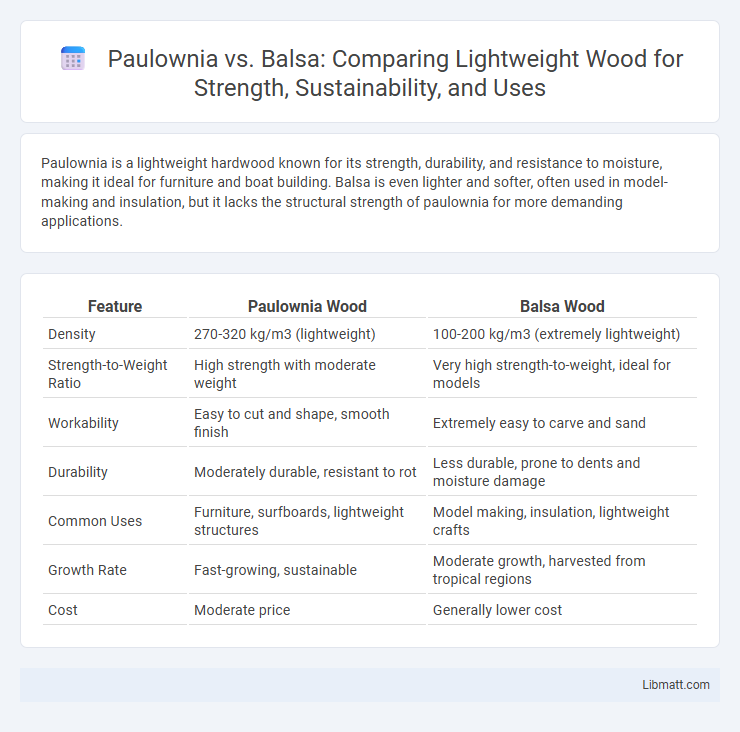

Paulownia is a lightweight hardwood known for its strength, durability, and resistance to moisture, making it ideal for furniture and boat building. Balsa is even lighter and softer, often used in model-making and insulation, but it lacks the structural strength of paulownia for more demanding applications.

Table of Comparison

| Feature | Paulownia Wood | Balsa Wood |

|---|---|---|

| Density | 270-320 kg/m3 (lightweight) | 100-200 kg/m3 (extremely lightweight) |

| Strength-to-Weight Ratio | High strength with moderate weight | Very high strength-to-weight, ideal for models |

| Workability | Easy to cut and shape, smooth finish | Extremely easy to carve and sand |

| Durability | Moderately durable, resistant to rot | Less durable, prone to dents and moisture damage |

| Common Uses | Furniture, surfboards, lightweight structures | Model making, insulation, lightweight crafts |

| Growth Rate | Fast-growing, sustainable | Moderate growth, harvested from tropical regions |

| Cost | Moderate price | Generally lower cost |

Introduction to Paulownia and Balsa Wood

Paulownia and balsa wood are prized for their exceptional lightweight properties and high strength-to-weight ratios, making them popular in aerospace, model building, and lightweight furniture. Paulownia features a fine, straight grain with moderate hardness, offering better durability compared to the ultra-light, soft texture of balsa, which is the lightest commercial wood worldwide. Your choice between Paulownia and balsa depends on the balance you seek between strength, weight, and workability for specific applications.

Botanical Origins and Growth Patterns

Paulownia, native to East Asia, belongs to the Paulowniaceae family and is characterized by its rapid growth, often reaching maturity within 10 years. Balsa, classified under the Malvaceae family and originating from South America, grows quickly but typically matures in 5 to 10 years with a more uniform wood structure. Understanding these botanical origins and growth patterns helps you select the ideal lightweight timber for applications requiring speed and sustainability.

Density and Weight Comparison

Paulownia wood has a density ranging from 0.28 to 0.35 g/cm3, making it lightweight but slightly denser than balsa, which typically has a density between 0.10 and 0.15 g/cm3. The higher density of paulownia contributes to greater strength and durability, while balsa's ultra-low density results in exceptional lightness ideal for model building and insulation. Weight-wise, balsa is approximately half or less the weight of paulownia for the same volume, influencing their respective uses in applications requiring lightweight yet sturdy materials.

Strength and Durability Differences

Paulownia wood offers a superior strength-to-weight ratio compared to balsa, making it more durable for structural applications. While balsa is lighter and easier to shape, its lower density results in reduced resistance to impact and wear. Paulownia's hardness and natural resistance to decay enhance its longevity, especially in outdoor or load-bearing uses.

Workability and Ease of Processing

Paulownia wood offers excellent workability due to its lightweight, straight grain, and low density, making it easy to cut, carve, and shape with standard woodworking tools. Balsa wood, known as one of the lightest woods, is extremely soft and pliable, allowing for effortless sanding and fast adhesives drying but requires careful handling to prevent dents and damage. Both woods are favored for model making and lightweight construction, yet Paulownia's comparatively higher durability provides greater resistance during processing.

Cost Analysis and Market Availability

Paulownia wood generally costs more than balsa due to its faster growth rate and durability, making it a premium option in the lightweight timber market. Balsa remains widely available and affordable because of its long-established cultivation and high demand for model-making and insulation purposes. Market availability of paulownia is expanding, but balsa's consistent supply and lower price maintain its dominance in cost-sensitive applications.

Sustainability and Environmental Impact

Paulownia wood is highly sustainable due to its rapid growth rate and ability to regenerate from its root system, making it an eco-friendly choice for reforestation and timber production. Balsa trees also grow quickly and sequester carbon efficiently, but their cultivation often requires more water and can lead to soil depletion if not managed properly. Both woods offer renewable alternatives to hardwoods, with Paulownia providing superior carbon capture and soil preservation benefits compared to balsa.

Typical Applications in Industry

Paulownia wood is widely used in furniture making, musical instruments, and lightweight construction due to its strength-to-weight ratio and natural resistance to decay. Balsa wood is predominantly favored in model building, wind turbine blades, and marine applications because of its exceptional lightness and insulating properties. Your choice between Paulownia and balsa hinges on specific industry requirements such as durability, weight, and application environment.

Pros and Cons of Paulownia vs Balsa

Paulownia wood offers a lightweight, strong, and moisture-resistant option ideal for furniture and boat building, but it is typically more expensive and less widely available than balsa. Balsa is one of the lightest woods available, providing exceptional buoyancy and easy workability for model-making and lightweight structures, yet it lacks the durability and resistance to water that Paulownia possesses. Choosing between Paulownia and balsa depends on the project's requirements for strength, weight, cost, and environmental exposure.

Which Wood is Best for Your Project?

Paulownia wood offers a lightweight yet durable option with natural resistance to moisture and rot, making it ideal for outdoor projects and furniture. Balsa wood is exceptionally light and easy to carve, favored for model building and applications requiring minimal weight but less durability. To choose the best wood for your project, consider Paulownia for strength and weather resistance, while Balsa suits precision work and indoor use where weight savings are critical.

Paulownia vs balsa Infographic

libmatt.com

libmatt.com