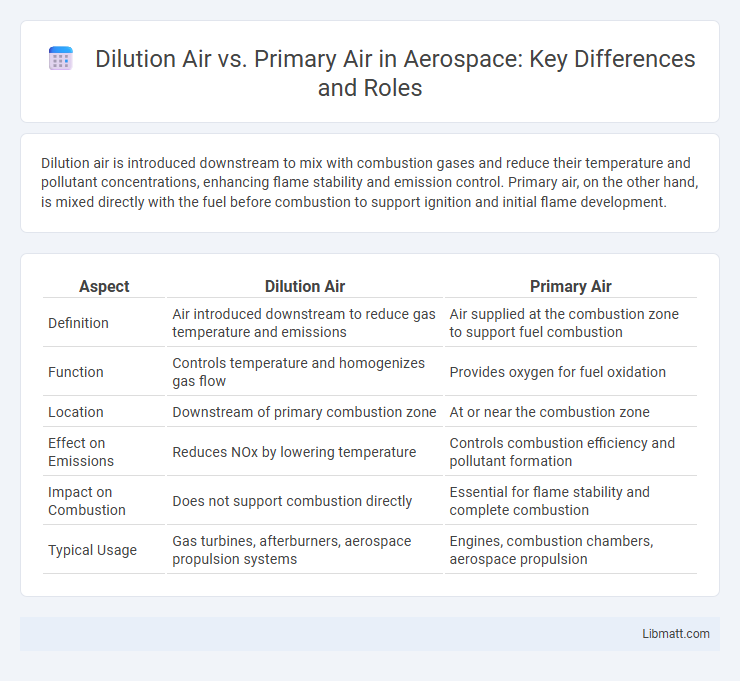

Dilution air is introduced downstream to mix with combustion gases and reduce their temperature and pollutant concentrations, enhancing flame stability and emission control. Primary air, on the other hand, is mixed directly with the fuel before combustion to support ignition and initial flame development.

Table of Comparison

| Aspect | Dilution Air | Primary Air |

|---|---|---|

| Definition | Air introduced downstream to reduce gas temperature and emissions | Air supplied at the combustion zone to support fuel combustion |

| Function | Controls temperature and homogenizes gas flow | Provides oxygen for fuel oxidation |

| Location | Downstream of primary combustion zone | At or near the combustion zone |

| Effect on Emissions | Reduces NOx by lowering temperature | Controls combustion efficiency and pollutant formation |

| Impact on Combustion | Does not support combustion directly | Essential for flame stability and complete combustion |

| Typical Usage | Gas turbines, afterburners, aerospace propulsion systems | Engines, combustion chambers, aerospace propulsion |

Understanding Dilution Air and Primary Air

Dilution air and primary air serve distinct roles in combustion and industrial processes; primary air is introduced to supply the necessary oxygen for fuel combustion, ensuring optimal flame stability and efficient burning. Dilution air, on the other hand, is added downstream of the combustion zone to reduce flue gas temperatures and control emissions by lowering oxygen concentration and gas velocity. Proper management of both air streams is critical for achieving efficient combustion, minimizing pollutant formation, and maintaining system safety.

Key Differences Between Dilution Air and Primary Air

Dilution air is introduced downstream of the combustion zone to reduce flue gas temperature and pollutant concentrations, while primary air is mixed with fuel before or during combustion to support the initial burning process. Primary air directly influences the combustion efficiency and flame stability, whereas dilution air adjusts the overall flue gas composition and temperature for emission control. Your understanding of these distinctions is crucial for optimizing combustion systems and improving environmental compliance.

Roles of Dilution Air in Combustion Systems

Dilution air plays a critical role in combustion systems by reducing flame temperature and controlling emissions such as NOx formation. It is introduced downstream of the burner, mixing with hot combustion gases to lower their temperature and improve flame stability. In contrast, primary air is used to supply oxygen for fuel combustion and achieve proper fuel-air mixing at the burner zone.

Functions of Primary Air in Fuel Burning

Primary air is essential in fuel burning as it supplies the necessary oxygen for efficient combustion, helping to ignite and sustain the fuel's flame. It also aids in transporting pulverized coal or fuel particles into the combustion chamber, ensuring consistent fuel-air mixing for optimal burning. Proper control of primary air flow directly improves combustion efficiency, reduces emissions, and stabilizes flame temperature in your boiler or furnace system.

Importance of Proper Air Balance

Proper air balance between dilution air and primary air is crucial for efficient combustion and optimal burner performance. Maintaining the correct ratio ensures complete fuel combustion, reduces emissions, and prevents overheating or flame instability. You can improve system longevity and energy efficiency by carefully adjusting dilution and primary air flows to meet specific operational requirements.

Impact on Combustion Efficiency

Dilution air reduces flame temperature by adding inert gases, which can lower combustion efficiency by decreasing heat release and causing incomplete fuel combustion. Primary air directly supports combustion by mixing with fuel, enhancing flame stability and improving combustion efficiency through more complete oxidation. Optimizing the balance between primary and dilution air ensures maximum thermal efficiency and minimizes unburned fuel losses in your combustion process.

Airflow Control Methods in Industrial Systems

Dilution air and primary air play distinct roles in industrial airflow control methods, with primary air supplying the combustion process and dilution air regulating temperature and emissions downstream. Accurate modulation of these airflow streams enables optimized combustion efficiency and reduced pollutant formation, crucial for maintaining system performance and compliance. Your ability to precisely control dilution air enhances process stability and environmental outcomes in industrial operations.

Effects on Emissions and Environmental Compliance

Dilution air reduces combustion temperature by mixing with flue gases, thereby lowering NOx emissions and aiding in meeting stringent environmental regulations. Primary air controls fuel combustion by supplying the necessary oxygen, directly influencing CO and particulate matter emissions. Optimizing the balance between dilution air and primary air is critical for achieving regulatory compliance and minimizing the environmental impact of industrial combustion processes.

Common Applications in HVAC and Boilers

Dilution air is primarily used in HVAC systems to reduce flue gas temperatures and control emissions, ensuring safer exhaust conditions and improved combustion efficiency. Primary air is crucial in boilers as it provides the necessary oxygen for fuel combustion, directly affecting flame stability and heat generation. Understanding the roles of both air types can enhance your system's performance and emission control.

Best Practices for Managing Dilution and Primary Air

Managing dilution air and primary air effectively requires precise control of airflow rates to optimize combustion efficiency and reduce emissions. Use adjustable dampers and real-time monitoring systems to balance primary air that supports fuel combustion with dilution air that cools and adjusts flue gas temperature. Implementing regular maintenance and calibration ensures your system maintains optimal air ratios, improving fuel efficiency and minimizing pollutant formation.

dilution air vs primary air Infographic

libmatt.com

libmatt.com