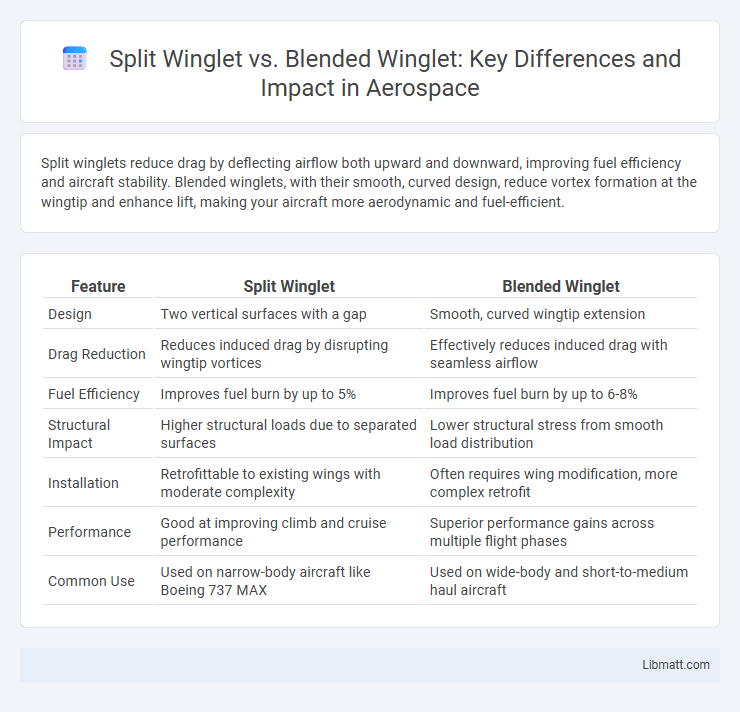

Split winglets reduce drag by deflecting airflow both upward and downward, improving fuel efficiency and aircraft stability. Blended winglets, with their smooth, curved design, reduce vortex formation at the wingtip and enhance lift, making your aircraft more aerodynamic and fuel-efficient.

Table of Comparison

| Feature | Split Winglet | Blended Winglet |

|---|---|---|

| Design | Two vertical surfaces with a gap | Smooth, curved wingtip extension |

| Drag Reduction | Reduces induced drag by disrupting wingtip vortices | Effectively reduces induced drag with seamless airflow |

| Fuel Efficiency | Improves fuel burn by up to 5% | Improves fuel burn by up to 6-8% |

| Structural Impact | Higher structural loads due to separated surfaces | Lower structural stress from smooth load distribution |

| Installation | Retrofittable to existing wings with moderate complexity | Often requires wing modification, more complex retrofit |

| Performance | Good at improving climb and cruise performance | Superior performance gains across multiple flight phases |

| Common Use | Used on narrow-body aircraft like Boeing 737 MAX | Used on wide-body and short-to-medium haul aircraft |

Introduction to Aircraft Winglets

Aircraft winglets enhance aerodynamic efficiency by reducing wingtip vortices, which decrease drag and improve fuel economy. Split Winglets feature dual surfaces with a vertical and horizontal extension, optimizing airflow and reducing induced drag more effectively than traditional designs. Your aircraft's performance and fuel savings can benefit significantly from choosing between Split Winglets and Blended Winglets based on their specific aerodynamic advantages.

What Are Split Winglets?

Split winglets are advanced aerodynamic devices mounted at the wingtips of aircraft to reduce drag and improve fuel efficiency by minimizing wingtip vortices. Unlike traditional blended winglets that feature a smooth curve transitioning from the wingtip, split winglets incorporate two separate vertical surfaces angled outward and downward, optimizing lift-to-drag ratio and reducing induced drag. This design enhances aircraft performance by increasing fuel savings, extending range, and lowering carbon emissions in commercial aviation.

What Are Blended Winglets?

Blended winglets are aerodynamic wingtip devices designed with a smooth, curved transition from the wing, reducing drag and improving fuel efficiency by minimizing vortex formation. Their seamless integration with the wing structure enhances lift-to-drag ratio without adding significant weight, making them a popular choice for commercial and private aircraft. Compared to split winglets, blended winglets offer superior performance in fuel savings and reduced emissions by optimizing airflow more effectively.

Design Differences: Split vs Blended Winglets

Split winglets feature a distinctive vertical and horizontal fin combination that reduces drag by directing airflow more efficiently, while blended winglets have a smooth, curved transition from the wingtip that minimizes turbulence. The aerodynamic design of split winglets often improves lift-to-drag ratio by managing vortex strength better in certain flight conditions. Your aircraft's performance can improve depending on which winglet design aligns best with its typical flying profile and operational requirements.

Aerodynamic Efficiency Comparison

Split winglets and blended winglets both enhance aerodynamic efficiency by reducing induced drag, but split winglets offer improved vortex dissipation through their segmented design, leading to better overall performance in high-lift conditions. Blended winglets provide smoother airflow transition with their curved structure, optimizing fuel savings during cruise by minimizing drag more effectively at steady speeds. Studies indicate split winglets deliver marginal gains in climb and maneuverability, whereas blended winglets excel in fuel efficiency and reduced emissions on long-haul flights.

Fuel Savings and Operational Cost Impact

Split winglets improve fuel savings by reducing drag and increasing lift efficiency, resulting in up to 3% fuel consumption reduction compared to conventional winglets. Blended winglets offer similar benefits but with a smoother aerodynamic transition, often yielding fuel savings of around 4-5%, which further decreases operational costs through lower fuel expenditure and extended engine lifespan. Airlines adopting blended winglets typically experience greater long-term cost benefits due to improved fuel efficiency and reduced maintenance requirements.

Installation and Retrofit Considerations

Split winglets and blended winglets differ significantly in installation and retrofit processes; split winglets typically require less structural modification due to their modular design, facilitating quicker retrofit on existing aircraft. Blended winglets demand more extensive aerodynamic integration and structural reinforcement, often necessitating detailed engineering assessments and longer installation timeframes. Airlines opting for split winglets benefit from reduced downtime and lower retrofit costs compared to the more complex installation of blended winglets.

Environmental Benefits: Emissions and Noise Reduction

Split winglets reduce drag more efficiently by managing vortices at the wingtips, leading to lower fuel consumption and decreased CO2 emissions, which directly benefits the environment. Blended winglets offer a smooth aerodynamic curve that minimizes turbulence and noise pollution around airports, improving community noise levels. Your choice between split and blended winglets can influence both emissions and noise footprint, contributing to greener and quieter flights.

Airlines and Aircraft Using Each Winglet Type

Split winglets are commonly adopted by airlines operating the Boeing 737 family, such as Southwest Airlines and Ryanair, enhancing fuel efficiency and range. Blended winglets, favored by carriers like United Airlines and Alaska Airlines, appear on Boeing 737 NG models, improving aerodynamics and reducing drag. Your choice between these winglet types depends on aircraft model compatibility and airline-specific performance goals.

Future Trends in Winglet Technology

Split winglets and blended winglets are evolving toward enhancing fuel efficiency and reducing carbon emissions in aircraft design. Emerging trends focus on integrating advanced materials and aerodynamic modeling to optimize lift-to-drag ratios, with split winglets offering improved vortex reduction and blended winglets providing smoother airflow attachment. Future developments include adaptive winglets with morphing capabilities for real-time performance adjustment, aligning with sustainability targets in the aviation industry.

Split Winglet vs Blended Winglet Infographic

libmatt.com

libmatt.com