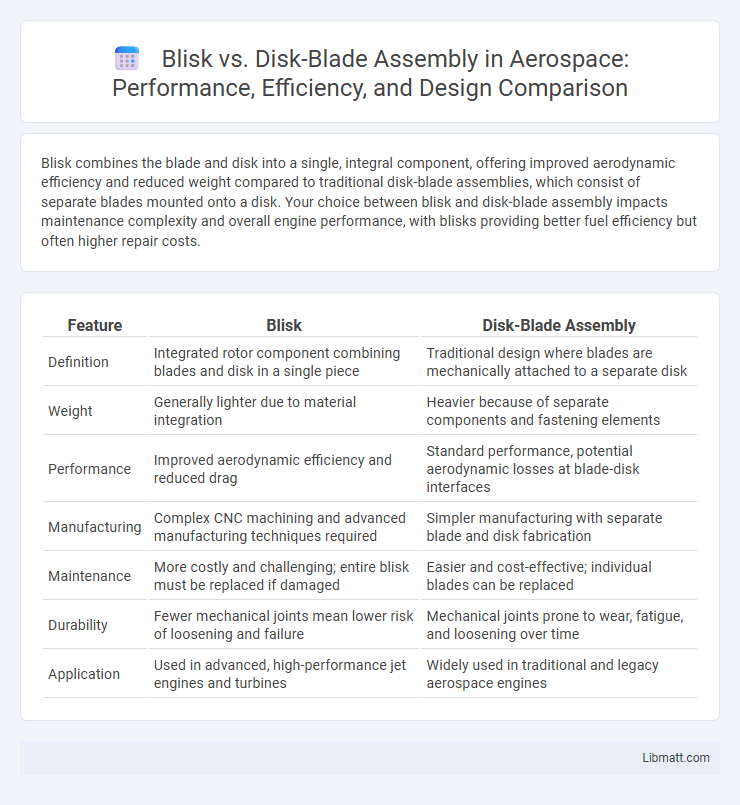

Blisk combines the blade and disk into a single, integral component, offering improved aerodynamic efficiency and reduced weight compared to traditional disk-blade assemblies, which consist of separate blades mounted onto a disk. Your choice between blisk and disk-blade assembly impacts maintenance complexity and overall engine performance, with blisks providing better fuel efficiency but often higher repair costs.

Table of Comparison

| Feature | Blisk | Disk-Blade Assembly |

|---|---|---|

| Definition | Integrated rotor component combining blades and disk in a single piece | Traditional design where blades are mechanically attached to a separate disk |

| Weight | Generally lighter due to material integration | Heavier because of separate components and fastening elements |

| Performance | Improved aerodynamic efficiency and reduced drag | Standard performance, potential aerodynamic losses at blade-disk interfaces |

| Manufacturing | Complex CNC machining and advanced manufacturing techniques required | Simpler manufacturing with separate blade and disk fabrication |

| Maintenance | More costly and challenging; entire blisk must be replaced if damaged | Easier and cost-effective; individual blades can be replaced |

| Durability | Fewer mechanical joints mean lower risk of loosening and failure | Mechanical joints prone to wear, fatigue, and loosening over time |

| Application | Used in advanced, high-performance jet engines and turbines | Widely used in traditional and legacy aerospace engines |

Introduction to Blisks and Disk-Blade Assemblies

Blisks (bladed disks) integrate blades and the disk into a single component, enhancing aerodynamic efficiency and reducing weight in turbomachinery. Disk-blade assemblies consist of separate blades mechanically attached to the disk, allowing easier maintenance but adding weight and potential aerodynamic losses. The blisk design improves performance by minimizing flow disturbances and structural stress compared to traditional disk-blade assemblies.

Historical Evolution in Turbomachinery Designs

Blisks represent an advanced integration where the blade and disk are manufactured as a single component, revolutionizing turbomachinery by reducing weight and improving aerodynamic efficiency compared to traditional disk-blade assemblies. Historically, disk-blade assemblies involved separately manufactured blades attached to the disk using mechanical or welding methods, which introduced stress concentrations and maintenance challenges. The evolution towards blisks stems from the demand for higher performance, durability, and reduced maintenance costs in aerospace and industrial gas turbines.

Structural Differences: Blisk vs Disk-Blade Assembly

Blisks integrate the blade and disk into a single, continuous component, eliminating the need for blade attachments and fasteners, which reduces overall weight and enhances aerodynamic efficiency. Disk-blade assemblies consist of separate blades mechanically attached to the disk through dovetail joints or fir-tree roots, facilitating easier blade replacement but increasing complexity and potential for mechanical failure. The monolithic design of blisks offers improved structural integrity and vibration resistance compared to the segmented disk-blade assembly approach.

Manufacturing Methods and Complexity

Blisk manufacturing involves precision machining and additive processes to create an integrated component from a single material block, reducing assembly steps but demanding advanced CNC and quality control techniques. Disk-blade assembly combines separately manufactured disks and blades using mechanical or welding methods, allowing for modular replacement but increasing complexity in alignment and fastening to ensure aerodynamic and structural integrity. The blisk's monolithic nature simplifies aerodynamic surfaces yet requires higher initial manufacturing investment, whereas disk-blade assemblies provide flexibility and easier repair at the cost of intricate joining processes.

Performance and Efficiency Comparison

Blisks integrate the blade and disk into a single component, significantly reducing weight and eliminating the need for blade-root attachments, which enhances aerodynamic performance and reduces stress concentrations. Disk-blade assemblies, featuring separate blades mounted onto the disk, allow easier blade replacement but incur higher maintenance costs and aerodynamic losses due to blade-root interfaces. Overall, blisks offer superior efficiency, improved fuel consumption, and increased durability compared to traditional disk-blade assemblies.

Maintenance and Repair Considerations

Blisks require specialized maintenance techniques since their integrated design prevents individual blade replacement, leading to higher repair costs and longer downtime compared to disk-blade assemblies. Disk-blade assemblies allow for simpler blade removal and replacement, facilitating quicker repairs and lower maintenance expenses. Your maintenance strategy should weigh the benefits of reduced assembly complexity against the potential for increased repair complexity and cost.

Cost Implications: Production to Lifecycle

Blisks offer reduced assembly costs and improved performance by eliminating blade-root joints, which can lower production expenses but require sophisticated manufacturing techniques that increase initial investment. Disk-blade assemblies have higher maintenance and inspection costs throughout their lifecycle due to the presence of separate blades susceptible to fatigue and damage. Your choice between blisk and disk-blade assembly impacts long-term operational costs and repair complexity, with blisks generally providing better lifecycle efficiency despite higher upfront production costs.

Common Applications in Aerospace and Energy

Blisks, integrating blades and disks into a single component, are widely employed in aerospace turbine engines to enhance aerodynamic efficiency and reduce weight, improving overall engine performance and fuel consumption. Disk-blade assemblies, involving separate blades mounted onto a disk, remain prevalent in energy sectors such as gas turbines for power generation, offering easier maintenance and blade replacement. Both technologies are critical in high-performance environments, with blisks favored for advanced jet engines and disk-blade assemblies preferred in flexible, high-stress energy applications.

Technological Advancements and Future Trends

Blisk technology integrates blades and disks into a single component, significantly enhancing engine efficiency and reducing weight compared to traditional disk-blade assemblies, which consist of separate parts. Recent advancements include additive manufacturing and advanced materials like titanium aluminide, improving blisk durability and enabling complex, aerodynamic blade designs. Future trends emphasize smart blisks with embedded sensors for real-time monitoring, predictive maintenance, and further performance optimization in aerospace propulsion systems.

Selecting the Right Solution: Factors to Consider

Selecting the right solution between a blisk and a disk-blade assembly depends on factors such as manufacturing complexity, maintenance requirements, and performance efficiency. Blisks offer advantages in reduced weight and improved aerodynamic efficiency but require advanced machining and repair techniques. Disk-blade assemblies provide easier blade replacement and lower initial costs, making them preferable for applications prioritizing maintenance flexibility.

blisk vs disk-blade assembly Infographic

libmatt.com

libmatt.com