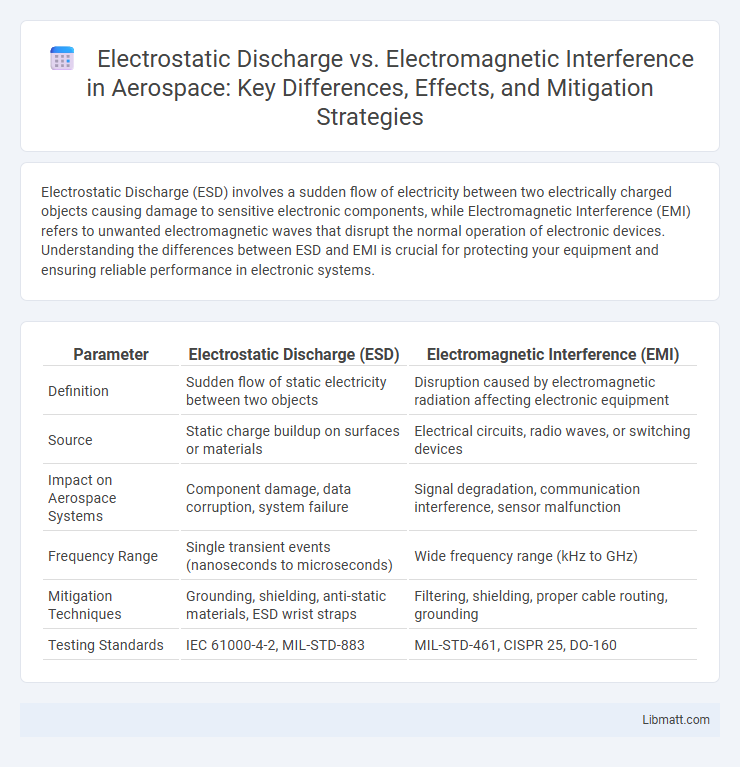

Electrostatic Discharge (ESD) involves a sudden flow of electricity between two electrically charged objects causing damage to sensitive electronic components, while Electromagnetic Interference (EMI) refers to unwanted electromagnetic waves that disrupt the normal operation of electronic devices. Understanding the differences between ESD and EMI is crucial for protecting your equipment and ensuring reliable performance in electronic systems.

Table of Comparison

| Parameter | Electrostatic Discharge (ESD) | Electromagnetic Interference (EMI) |

|---|---|---|

| Definition | Sudden flow of static electricity between two objects | Disruption caused by electromagnetic radiation affecting electronic equipment |

| Source | Static charge buildup on surfaces or materials | Electrical circuits, radio waves, or switching devices |

| Impact on Aerospace Systems | Component damage, data corruption, system failure | Signal degradation, communication interference, sensor malfunction |

| Frequency Range | Single transient events (nanoseconds to microseconds) | Wide frequency range (kHz to GHz) |

| Mitigation Techniques | Grounding, shielding, anti-static materials, ESD wrist straps | Filtering, shielding, proper cable routing, grounding |

| Testing Standards | IEC 61000-4-2, MIL-STD-883 | MIL-STD-461, CISPR 25, DO-160 |

Understanding Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) occurs when a sudden flow of electricity transfers between two electrically charged objects, typically caused by contact or proximity, leading to potential damage in sensitive electronic components. Unlike Electromagnetic Interference (EMI), which involves unwanted electromagnetic waves disrupting electronic signals, ESD involves direct electric shocks that can destroy microchips and semiconductors. Effective ESD protection requires grounding, the use of antistatic materials, and controlled environments to prevent costly failures in electronic manufacturing and operation.

Exploring Electromagnetic Interference (EMI)

Electromagnetic Interference (EMI) refers to the disruption of electronic devices caused by external electromagnetic fields, which can originate from radio frequencies, electrical circuits, or natural sources like lightning. EMI affects signal integrity and data transmission in sensitive equipment, leading to malfunctions or data loss, particularly in medical devices, communication systems, and aerospace technology. Shielding techniques, filtering, and grounding are key methods used to mitigate EMI and ensure the reliability and performance of electronic systems.

Key Differences Between ESD and EMI

Electrostatic Discharge (ESD) involves the sudden flow of electricity between two electrically charged objects, typically causing immediate damage to sensitive electronic components. Electromagnetic Interference (EMI) refers to the disruption of electronic signals caused by external electromagnetic fields, often resulting in performance degradation rather than instant failure. Understanding these key differences helps you design effective protection strategies for your electronic devices, ensuring reliability and longevity.

Common Sources of ESD in Electronics

Common sources of electrostatic discharge (ESD) in electronics include human contact, especially through handling sensitive components without proper grounding, and friction between materials such as plastics and packaging foam. Other notable sources are manufacturing equipment, conveyor belts, and dust particles, which can accumulate static charge and discharge suddenly. Understanding these ESD sources is crucial for implementing effective static control measures to protect electronic devices from damage.

Typical Origins of EMI in Electronic Systems

Typical origins of Electromagnetic Interference (EMI) in electronic systems include power lines, radio frequency transmitters, switching power supplies, and electric motors, which generate unwanted electromagnetic signals disrupting device operation. Unlike Electrostatic Discharge (ESD), which involves sudden voltage spikes caused by static electricity, EMI stems from continuous or intermittent electromagnetic noise emitted by active components and external sources. Understanding these sources helps you implement proper shielding and filtering techniques to protect sensitive electronics from performance degradation.

Impacts of ESD and EMI on Device Performance

Electrostatic discharge (ESD) causes sudden voltage spikes that can damage sensitive electronic components, leading to permanent device failure or data corruption. Electromagnetic interference (EMI) generates unwanted noise that disrupts signal integrity, resulting in degraded device performance, communication errors, and reduced reliability. Both ESD and EMI significantly impact device longevity, operational stability, and overall system efficiency in electronic systems.

Detection and Measurement Techniques for ESD and EMI

Electrostatic Discharge (ESD) detection relies on specialized equipment such as ESD simulators and field meters to measure voltage spikes and discharge events, while Electromagnetic Interference (EMI) is detected using spectrum analyzers and EMI receivers to capture radiated and conducted emissions across specific frequency ranges. Measurement techniques for ESD emphasize transient voltage characterization and discharge current waveform analysis, whereas EMI measurement standards focus on frequency-domain analysis, employing calibrated antennas and probes to quantify interference levels in compliance with CISPR, MIL-STD, or IEC regulations. Precise detection and measurement of both ESD and EMI are critical for safeguarding electronic devices, minimizing malfunctions, and ensuring compliance with international electromagnetic compatibility (EMC) standards.

Prevention Strategies for ESD and EMI

Prevention strategies for Electrostatic Discharge (ESD) emphasize grounding techniques, use of antistatic materials, and controlled humidity environments to minimize static buildup. For Electromagnetic Interference (EMI), shielding cables, proper grounding, and filtering devices are key methods to reduce electromagnetic noise and signal distortion. Implementing these targeted measures ensures your electronic systems operate reliably without disruptions caused by ESD or EMI.

Industry Standards for ESD and EMI Protection

Industry standards for Electrostatic Discharge (ESD) protection, such as the ANSI/ESD S20.20 and IEC 61340-5-1, define requirements for controlling, grounding, and dissipating static electricity in electronic environments. Electromagnetic Interference (EMI) protection standards include MIL-STD-461 and CISPR 22, which specify limits for electromagnetic emissions and immunity to ensure device compatibility and prevent signal disruption. Compliance with these standards ensures robust design and reliable operation of electronic systems across industries.

Future Trends in Mitigating ESD and EMI

Future trends in mitigating Electrostatic Discharge (ESD) and Electromagnetic Interference (EMI) include the development of advanced nanomaterials and conductive polymers that enhance shielding effectiveness while maintaining device miniaturization. Integration of AI-driven predictive analytics enables real-time monitoring and adaptive response to ESD and EMI events, improving overall system resilience. Investing in these cutting-edge technologies ensures Your electronic devices remain robust against evolving electromagnetic challenges.

Electrostatic Discharge vs Electromagnetic Interference Infographic

libmatt.com

libmatt.com