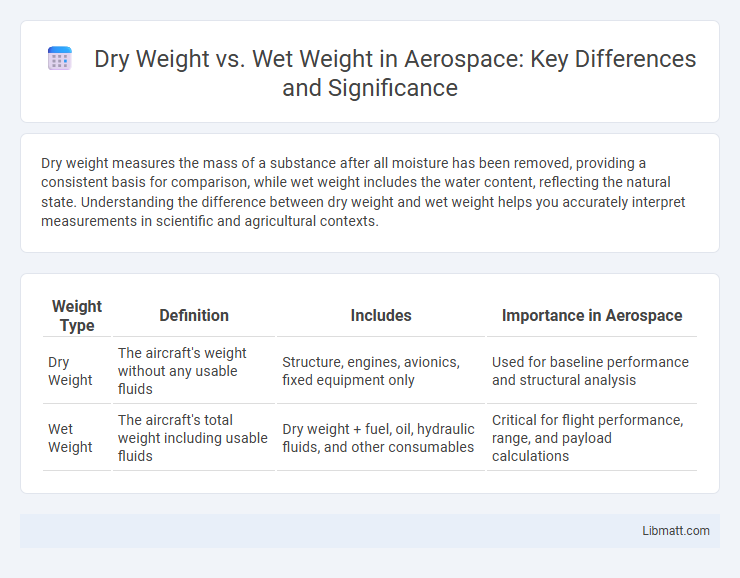

Dry weight measures the mass of a substance after all moisture has been removed, providing a consistent basis for comparison, while wet weight includes the water content, reflecting the natural state. Understanding the difference between dry weight and wet weight helps you accurately interpret measurements in scientific and agricultural contexts.

Table of Comparison

| Weight Type | Definition | Includes | Importance in Aerospace |

|---|---|---|---|

| Dry Weight | The aircraft's weight without any usable fluids | Structure, engines, avionics, fixed equipment only | Used for baseline performance and structural analysis |

| Wet Weight | The aircraft's total weight including usable fluids | Dry weight + fuel, oil, hydraulic fluids, and other consumables | Critical for flight performance, range, and payload calculations |

Understanding Dry Weight and Wet Weight

Dry weight refers to the mass of a substance after all moisture has been removed, providing a consistent basis for comparison in scientific measurements. Wet weight includes the total mass with water content, important for assessing organisms or materials in their natural, hydrated state. Understanding the distinction between dry weight and wet weight is crucial in fields like agriculture, biology, and food science to ensure accurate data analysis and reporting.

Key Differences Between Dry and Wet Weight

Dry weight refers to the mass of a substance after all moisture has been removed, while wet weight includes the total mass with water content intact. The key difference lies in moisture presence, affecting measurements in fields such as agriculture, biology, and material science. Understanding your sample's state helps ensure accurate data analysis and comparisons based on either dry or wet weight.

Why Dry Weight Matters

Dry weight is a crucial metric in biological and environmental studies because it provides an accurate measure of the actual mass of organic or inorganic material, excluding water content that can vary significantly. This standardization allows for consistent comparison of biomass, nutrient content, or soil composition across different samples and conditions. Understanding dry weight is essential for calculating precise concentrations of substances and assessing true organism growth or material density.

Importance of Wet Weight in Various Applications

Wet weight is crucial in fields such as marine biology, agriculture, and food science because it reflects the actual mass of organisms or materials with their inherent moisture content, essential for accurate ecological and nutritional assessments. Measuring wet weight allows for immediate evaluation of hydration levels, growth rates, and freshness, directly impacting research, crop management, and quality control processes. This parameter supports practical applications like determining yield, monitoring health conditions, and ensuring regulatory compliance across diverse scientific and industrial domains.

Factors Affecting Dry and Wet Weight

Factors affecting dry weight include moisture content, drying method, and biological composition, while wet weight varies due to water retention, environmental humidity, and specimen handling. Temperature, salinity, and time since collection also influence wet weight by altering water absorption or loss. Understanding these factors can help you accurately compare and interpret biomass data in ecological and biological studies.

Methods for Measuring Dry Weight

Methods for measuring dry weight typically involve removing all moisture content from a sample through processes such as oven drying at temperatures ranging from 60degC to 105degC until a constant weight is achieved. Freeze-drying or lyophilization is another precise technique that sublimates water at low temperatures and pressure, preserving sample integrity. Gravimetric analysis following desiccation enables accurate determination of dry weight critical in fields like biology, ecology, and material science.

Methods for Measuring Wet Weight

Methods for measuring wet weight commonly involve using a calibrated digital or mechanical scale to weigh the specimen immediately after collection to preserve moisture content. Samples are often blotted gently with absorbent paper to remove surface water without altering internal hydration before measurement. Precise timing and controlled environmental conditions during weighing improve accuracy and consistency in wet weight determination.

Common Uses in Industry and Agriculture

Dry weight and wet weight measurements are crucial in agriculture for determining the moisture content of crops, influencing storage, pricing, and quality control. In the food industry, dry weight provides a standardized metric for ingredient formulation and nutritional analysis, while wet weight is essential for freshness assessment and processing yield calculations. Your understanding of these weight distinctions can optimize product quality and operational efficiency in both sectors.

Pros and Cons of Dry vs Wet Weight

Dry weight offers precise measurement of the actual material content, ideal for scientific analysis and hydration studies, but requires time-consuming sample preparation and can cause structural changes due to moisture removal. Wet weight provides a quick, realistic assessment of your sample's total mass including water content, beneficial for biological studies and immediate measurements, yet it may lead to variability and less accuracy in comparing samples with different moisture levels. Choosing between dry and wet weight depends on the need for accuracy versus speed, and the specific context of your measurement goals.

Choosing the Right Measurement for Your Needs

Selecting between dry weight and wet weight depends on the specific application and accuracy requirements; dry weight excludes water content, providing a more consistent and reliable measure for precise scientific analysis. Wet weight includes the natural moisture of the sample, making it suitable for ecological studies and scenarios where water content impacts the overall mass. Understanding the context, such as biological research or material processing, ensures the use of the appropriate measurement for valid and meaningful results.

Dry weight vs Wet weight Infographic

libmatt.com

libmatt.com