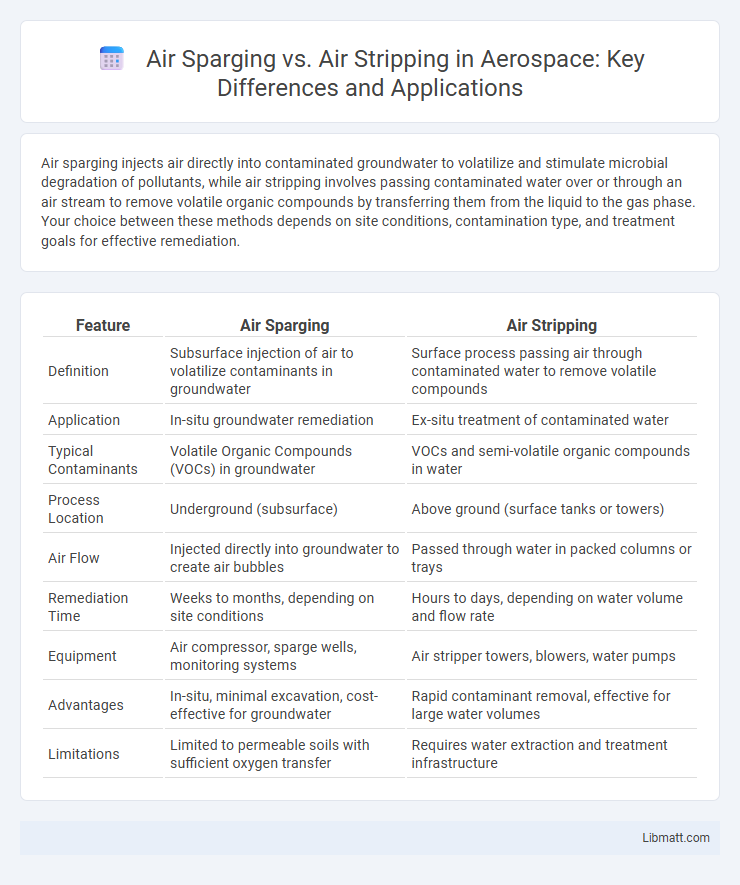

Air sparging injects air directly into contaminated groundwater to volatilize and stimulate microbial degradation of pollutants, while air stripping involves passing contaminated water over or through an air stream to remove volatile organic compounds by transferring them from the liquid to the gas phase. Your choice between these methods depends on site conditions, contamination type, and treatment goals for effective remediation.

Table of Comparison

| Feature | Air Sparging | Air Stripping |

|---|---|---|

| Definition | Subsurface injection of air to volatilize contaminants in groundwater | Surface process passing air through contaminated water to remove volatile compounds |

| Application | In-situ groundwater remediation | Ex-situ treatment of contaminated water |

| Typical Contaminants | Volatile Organic Compounds (VOCs) in groundwater | VOCs and semi-volatile organic compounds in water |

| Process Location | Underground (subsurface) | Above ground (surface tanks or towers) |

| Air Flow | Injected directly into groundwater to create air bubbles | Passed through water in packed columns or trays |

| Remediation Time | Weeks to months, depending on site conditions | Hours to days, depending on water volume and flow rate |

| Equipment | Air compressor, sparge wells, monitoring systems | Air stripper towers, blowers, water pumps |

| Advantages | In-situ, minimal excavation, cost-effective for groundwater | Rapid contaminant removal, effective for large water volumes |

| Limitations | Limited to permeable soils with sufficient oxygen transfer | Requires water extraction and treatment infrastructure |

Introduction to Air Sparging and Air Stripping

Air sparging is an in-situ remediation technique that injects air into contaminated groundwater to volatilize and biologically degrade pollutants. Air stripping is an ex-situ method that transfers volatile contaminants from water to air by aeration in treatment units such as packed towers or tray columns. Both technologies target volatile organic compounds (VOCs) but differ in application, with air sparging treating subsurface plumes and air stripping treating extracted groundwater.

How Air Sparging Works

Air sparging involves injecting air directly into contaminated groundwater to volatilize and remove pollutants by transferring them into the soil gas phase. This process enhances the biodegradation of volatile organic compounds (VOCs) by stimulating aerobic microbial activity within the saturated zone. Your remediation project benefits from air sparging by efficiently treating subsurface contaminants without extensive soil excavation.

How Air Stripping Operates

Air stripping operates by forcing contaminated water through a packed tower where air is blown counter-currently, enabling volatile organic compounds (VOCs) to transfer from the liquid phase to the gas phase. This process efficiently removes VOCs such as benzene and trichloroethylene by exploiting their volatility and Henry's law constant. Your water treatment system benefits from air stripping's ability to rapidly reduce pollutant concentrations in groundwater or aqueous solutions.

Key Differences Between Air Sparging and Air Stripping

Air sparging injects air directly into contaminated groundwater to volatilize and strip volatile organic compounds (VOCs) in situ, whereas air stripping involves transferring contaminated water to an above-ground treatment system where air removes VOCs through mass transfer. Air sparging is primarily used for remediation of subsurface soil and groundwater, offering targeted in-well treatment, while air stripping is suited for treating extracted groundwater ex situ. Key differences include operational location, treatment mechanism, and system design complexity, with air sparging requiring subsurface injection wells and air stripping relying on packed columns or tray towers.

Contaminants Treated by Each Method

Air sparging effectively treats volatile organic compounds (VOCs) such as benzene, toluene, ethylbenzene, and xylene (BTEX) by injecting air into contaminated groundwater to volatilize and biodegrade pollutants. Air stripping is highly efficient for removing dissolved VOCs and semi-volatile organic compounds (SVOCs) from groundwater and wastewater by transferring contaminants into the air phase through packed towers or trays. Both methods target organic contaminants but air sparging is better suited for saturated zones, while air stripping is optimal for treating extracted water with high contaminant concentrations.

Advantages of Air Sparging

Air sparging offers effective in-situ remediation by injecting air directly into the saturated zone, which enhances the volatilization and biodegradation of contaminants without extensive soil excavation. This technique reduces treatment time and operational costs compared to air stripping, which typically requires extraction and off-site treatment of contaminated groundwater. Your site benefits from minimized vapor intrusion risks and improved groundwater quality through targeted contaminant removal.

Benefits of Air Stripping

Air stripping effectively removes volatile organic compounds (VOCs) from groundwater and contaminated soil vapor by transferring pollutants from water to air, making it a rapid and efficient remediation method. Its high removal efficiency reduces toxicity and improves water quality, supporting compliance with environmental regulations. You benefit from lower operational costs and simpler system design compared to air sparging, especially in treating large volumes of groundwater with high contaminant levels.

Limitations and Challenges of Each Technology

Air sparging faces limitations such as difficulty in treating low permeability soils and the risk of contaminant rebound due to incomplete volatilization, while air stripping struggles with the need for effective off-gas treatment to prevent air pollution and is less suitable for contaminants with low volatility. Both technologies require site-specific conditions to optimize performance, with air sparging depending heavily on subsurface hydrogeology and air stripping needing precise control of air-to-water ratios. Your remediation strategy should account for these challenges to ensure effective contaminant removal and regulatory compliance.

Site Selection Criteria for Air Sparging vs Air Stripping

Site selection criteria for air sparging prioritize permeable saturated soils with shallow groundwater tables to enhance contaminant volatilization directly in the subsurface. Air stripping requires above-ground treatment facilities and is suited for contaminated groundwater with volatile organic compounds (VOCs) that can be easily separated via aeration. Site hydrogeology, contaminant type and concentration, and proximity to sensitive receptors are critical factors influencing the decision between air sparging and air stripping methods.

Choosing the Right Remediation Method

Air sparging injects air below the water table to volatilize and biodegrade contaminants in groundwater, while air stripping removes volatile organic compounds (VOCs) from contaminated water by transferring them to the air phase. Your selection depends on site conditions, such as contaminant type, depth, and groundwater flow, with air sparging suited for dissolved-phase hydrocarbons and air stripping effective for treating extracted water above ground. Assessing remediation goals and environmental impact ensures optimal method choice for efficient contaminant removal.

air sparging vs air stripping Infographic

libmatt.com

libmatt.com