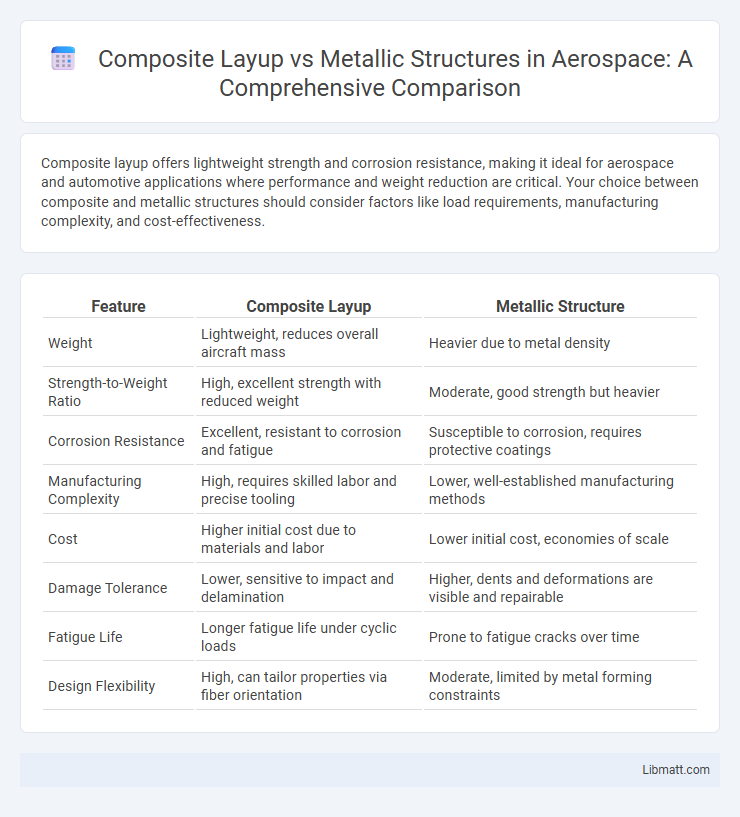

Composite layup offers lightweight strength and corrosion resistance, making it ideal for aerospace and automotive applications where performance and weight reduction are critical. Your choice between composite and metallic structures should consider factors like load requirements, manufacturing complexity, and cost-effectiveness.

Table of Comparison

| Feature | Composite Layup | Metallic Structure |

|---|---|---|

| Weight | Lightweight, reduces overall aircraft mass | Heavier due to metal density |

| Strength-to-Weight Ratio | High, excellent strength with reduced weight | Moderate, good strength but heavier |

| Corrosion Resistance | Excellent, resistant to corrosion and fatigue | Susceptible to corrosion, requires protective coatings |

| Manufacturing Complexity | High, requires skilled labor and precise tooling | Lower, well-established manufacturing methods |

| Cost | Higher initial cost due to materials and labor | Lower initial cost, economies of scale |

| Damage Tolerance | Lower, sensitive to impact and delamination | Higher, dents and deformations are visible and repairable |

| Fatigue Life | Longer fatigue life under cyclic loads | Prone to fatigue cracks over time |

| Design Flexibility | High, can tailor properties via fiber orientation | Moderate, limited by metal forming constraints |

Introduction to Composite Layup and Metallic Structures

Composite layup involves layering different materials such as carbon fiber, glass fiber, or aramid fibers, bonded with a resin matrix to produce lightweight, high-strength structures widely used in aerospace, automotive, and sports industries. Metallic structures, typically fabricated from aluminum, steel, or titanium alloys, offer excellent tensile strength, durability, and conductivity but often at higher weight and corrosion susceptibility. The choice between composite layup and metallic structures depends on specific application requirements like weight reduction, mechanical performance, and cost-efficiency.

Material Composition and Properties

Composite layups consist of multiple layers of fiber-reinforced materials, such as carbon or glass fibers embedded in a polymer matrix, providing high strength-to-weight ratios and excellent corrosion resistance. Metallic structures are typically made from metals like aluminum, steel, or titanium, offering superior ductility, thermal conductivity, and ease of fabrication but often at the cost of higher weight and susceptibility to corrosion. The anisotropic properties of composite layups allow tailored mechanical performance, whereas metallic structures are generally isotropic with uniform material behavior.

Manufacturing Processes Comparison

Composite layup manufacturing involves layering fiber reinforcements soaked in resin onto molds, offering precise control over fiber orientation and thickness for tailored strength-to-weight ratios. Metallic structure fabrication typically includes processes like casting, forging, and machining, which emphasize material ductility and uniformity but may result in higher weight compared to composites. Your choice between composite layup and metallic structures impacts manufacturing time, cost, and design flexibility, with composites enabling more complex shapes and reduced assembly steps.

Structural Weight and Efficiency

Composite layup offers significant advantages in structural weight and efficiency compared to metallic structures due to its high strength-to-weight ratio and customizable fiber orientation. These materials reduce overall weight by up to 30-50%, translating directly into improved fuel efficiency and payload capacity in aerospace and automotive applications. Optimized composite layups enhance load distribution and stiffness while minimizing material usage, outperforming traditional metal alloys in both performance and energy consumption.

Strength and Durability Analysis

Composite layups offer superior strength-to-weight ratios compared to metallic structures, enabling greater load-bearing capacity with reduced mass. The layered arrangement in composites enhances durability by resisting fatigue crack propagation and corrosion, common weaknesses in metals. Metallic structures, while robust under impact and high-temperature conditions, often suffer from stress concentration and corrosion-related degradation over time.

Corrosion Resistance and Environmental Performance

Composite layup structures offer superior corrosion resistance compared to metallic structures due to their non-metallic fiber-reinforced polymer matrix, which inherently resists oxidation and chemical degradation. Unlike aluminum or steel, composites do not suffer from galvanic corrosion, reducing maintenance costs and extending service life in harsh environments such as marine or chemical exposure. Environmental performance of composites is enhanced by their lightweight nature, which reduces fuel consumption and emissions during transportation, though end-of-life recycling challenges remain compared to metallic materials which are more easily recycled.

Repairability and Maintenance Considerations

Composite layup structures often require specialized repair techniques involving resin application and curing, which can be time-consuming and demand certified technicians. Metallic structures typically allow for more straightforward repairs such as welding, riveting, or part replacement, enabling faster turnaround and easier maintenance. The cost and accessibility of tools and expertise for composites generally exceed those for metals, impacting long-term repairability and maintenance planning.

Cost Implications and Lifecycle Economics

Composite layup often involves higher initial manufacturing costs due to expensive raw materials and labor-intensive processes, but offers significant weight savings that reduce fuel consumption and maintenance expenses over the asset's lifecycle. Metallic structures typically have lower upfront costs and easier fabrication, yet their higher weight can increase operational costs and frequency of repairs due to corrosion and fatigue. Understanding your specific application's usage patterns is crucial to evaluate the total cost of ownership and lifecycle economics between composite layup and metallic structures.

Applications in Aerospace and Automotive Industries

Composite layup techniques enable lightweight, high-strength structures that improve fuel efficiency and performance in aerospace and automotive industries. Aerospace applications include aircraft fuselages, wings, and helicopter blades where weight reduction and fatigue resistance are critical. In automotive manufacturing, composite materials are used for body panels, chassis components, and crash structures to enhance safety while decreasing overall vehicle weight.

Future Trends and Technological Advancements

Future trends in composite layup emphasize automation, advanced robotics, and AI-driven quality control to enhance precision and reduce costs, surpassing traditional metallic structures in lightweight performance and fuel efficiency. Technological advancements like additive manufacturing and hybrid material integration enable composites to achieve superior strength-to-weight ratios and corrosion resistance compared to metallic counterparts. Your aerospace or automotive projects benefit from these innovations through improved durability, sustainability, and design flexibility that metallic structures struggle to match.

composite layup vs metallic structure Infographic

libmatt.com

libmatt.com