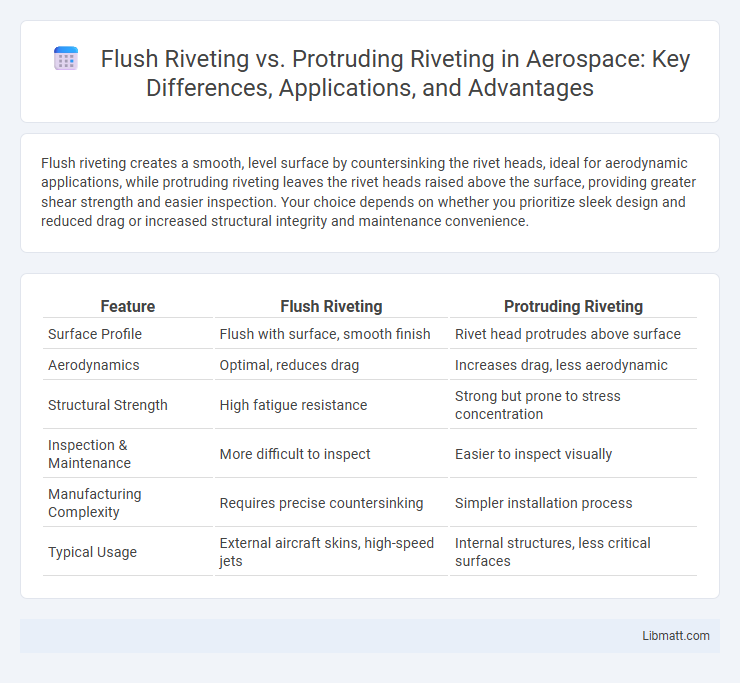

Flush riveting creates a smooth, level surface by countersinking the rivet heads, ideal for aerodynamic applications, while protruding riveting leaves the rivet heads raised above the surface, providing greater shear strength and easier inspection. Your choice depends on whether you prioritize sleek design and reduced drag or increased structural integrity and maintenance convenience.

Table of Comparison

| Feature | Flush Riveting | Protruding Riveting |

|---|---|---|

| Surface Profile | Flush with surface, smooth finish | Rivet head protrudes above surface |

| Aerodynamics | Optimal, reduces drag | Increases drag, less aerodynamic |

| Structural Strength | High fatigue resistance | Strong but prone to stress concentration |

| Inspection & Maintenance | More difficult to inspect | Easier to inspect visually |

| Manufacturing Complexity | Requires precise countersinking | Simpler installation process |

| Typical Usage | External aircraft skins, high-speed jets | Internal structures, less critical surfaces |

Introduction to Riveting Techniques

Flush riveting creates a smooth surface by countersinking rivet heads, ideal for aerodynamic applications in aerospace and automotive industries. Protruding riveting features rivet heads that extend above the surface, offering simpler installation and stronger mechanical fastening commonly used in structural and heavy-duty metalwork. Both techniques optimize joint strength and durability but differ significantly in applications based on design requirements and aesthetic considerations.

What is Flush Riveting?

Flush riveting is a fastening technique where rivet heads are countersunk into the material surface, creating a smooth, aerodynamic finish critical in aerospace and automotive industries. This method reduces drag and enhances structural integrity by minimizing surface irregularities compared to protruding riveting. Flush rivets are essential in applications requiring both strength and streamlined surfaces.

What is Protruding Riveting?

Protruding riveting involves creating rivet heads that extend above the surface of the materials being joined, providing a strong mechanical fastening ideal for applications where flush surfaces are not critical. This method offers increased shear strength and is commonly used in structures requiring rapid assembly and high durability, such as in aerospace and heavy machinery. Understanding the differences between protruding and flush riveting can help you choose the most suitable technique for your specific engineering or construction needs.

Key Differences: Flush vs Protruding Riveting

Flush riveting creates a smooth surface by countersinking the rivet head, ideal for aerodynamic applications where minimizing drag is crucial. Protruding riveting leaves the rivet head exposed, offering faster installation and easier inspection but increases surface roughness. Your choice between flush and protruding riveting impacts both structural performance and aesthetic requirements in manufacturing.

Strength and Durability Comparison

Flush riveting offers superior aerodynamics and a smoother surface finish, making it ideal for high-speed applications, while protruding riveting provides greater shear strength due to its larger grip area. In terms of durability, flush rivets reduce stress concentrations and fatigue risk, enhancing the lifespan of structures exposed to dynamic loads. Your choice depends on whether aerodynamic efficiency or maximum shear strength is the primary design requirement.

Applications of Flush Riveting

Flush riveting is primarily used in aerospace and automotive industries where aerodynamic efficiency and smooth surfaces are critical to performance and safety. This method allows for a seamless finish by setting the rivet head flush with the material surface, reducing drag and preventing structural stress concentrations. Flush riveting is essential in aircraft fuselage assembly, racecar body panels, and naval shipbuilding, where maintaining structural integrity without compromising on surface smoothness is paramount.

Applications of Protruding Riveting

Protruding riveting is commonly used in applications where structural strength and ease of inspection are critical, such as in shipbuilding, heavy machinery, and large steel structures. These rivets provide strong, durable joints that can withstand high stress and vibration, making them ideal for industrial and construction projects. Your choice of protruding riveting ensures secure assembly where flush aesthetics are secondary to performance and reliability.

Advantages of Flush Riveting

Flush riveting offers aerodynamic benefits by creating a smooth surface, reducing drag in applications such as aerospace and automotive industries. This method enhances structural integrity by evenly distributing stress, minimizing the risk of fatigue and corrosion around the rivet site. Flush rivets improve aesthetic appeal and facilitate easy maintenance, making them ideal for visible surfaces where appearance and performance are critical.

Advantages of Protruding Riveting

Protruding riveting offers easier installation and inspection due to its visible heads, allowing for quick confirmation of rivet integrity. The raised heads provide better stress distribution, enhancing joint strength in dynamic or high-load applications. Protruding rivets are also more adaptable to varying material thicknesses and surface irregularities, reducing the need for precise countersinking.

Choosing the Right Riveting Method

Choosing the right riveting method depends on the specific application requirements and surface finish desired. Flush riveting provides a smooth, aerodynamic surface ideal for aerospace and automotive uses, reducing drag and improving aesthetics, while protruding riveting offers easier installation and maintenance access for structural or heavy-duty applications. Your choice should balance factors like load capacity, material thickness, and exposure to environmental conditions to ensure optimal performance and durability.

Flush Riveting vs Protruding Riveting Infographic

libmatt.com

libmatt.com