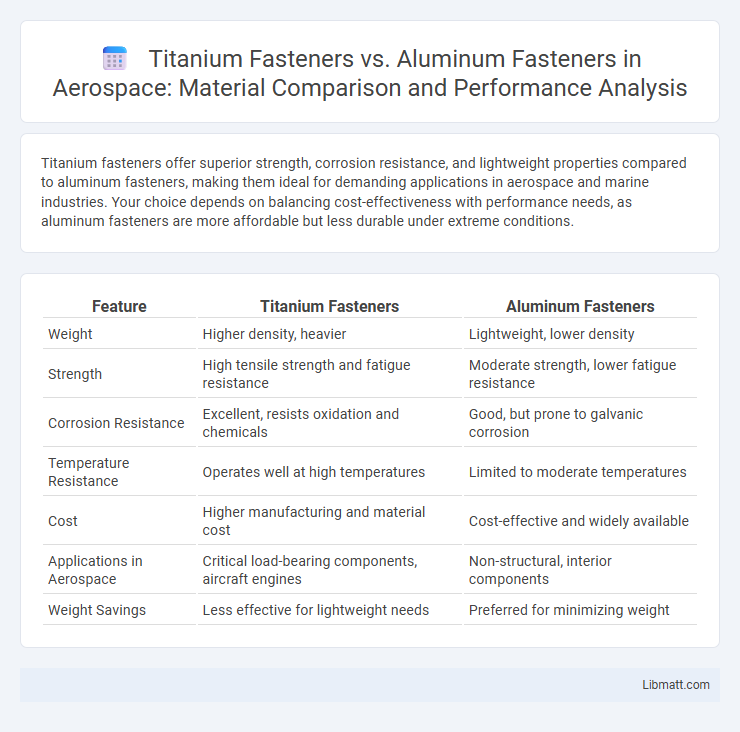

Titanium fasteners offer superior strength, corrosion resistance, and lightweight properties compared to aluminum fasteners, making them ideal for demanding applications in aerospace and marine industries. Your choice depends on balancing cost-effectiveness with performance needs, as aluminum fasteners are more affordable but less durable under extreme conditions.

Table of Comparison

| Feature | Titanium Fasteners | Aluminum Fasteners |

|---|---|---|

| Weight | Higher density, heavier | Lightweight, lower density |

| Strength | High tensile strength and fatigue resistance | Moderate strength, lower fatigue resistance |

| Corrosion Resistance | Excellent, resists oxidation and chemicals | Good, but prone to galvanic corrosion |

| Temperature Resistance | Operates well at high temperatures | Limited to moderate temperatures |

| Cost | Higher manufacturing and material cost | Cost-effective and widely available |

| Applications in Aerospace | Critical load-bearing components, aircraft engines | Non-structural, interior components |

| Weight Savings | Less effective for lightweight needs | Preferred for minimizing weight |

Introduction to Titanium and Aluminum Fasteners

Titanium fasteners offer superior corrosion resistance and strength-to-weight ratio compared to aluminum fasteners, making them ideal for demanding applications in aerospace and marine industries. Aluminum fasteners are lightweight and cost-effective, suitable for less critical environments where minimizing weight is important. Understanding the distinct properties of your fasteners ensures optimal performance and longevity in your specific project.

Material Properties Comparison

Titanium fasteners offer superior strength-to-weight ratio and exceptional corrosion resistance, making them ideal for high-stress environments, while aluminum fasteners are lighter but less strong and more prone to corrosion and fatigue. Titanium's high tensile strength and resistance to extreme temperatures provide durability for aerospace and automotive applications, whereas aluminum fasteners are often preferred for lower-load uses where cost and weight savings are priorities. Your choice between these materials should balance the need for performance, longevity, and environmental exposure based on the specific application.

Strength and Durability Differences

Titanium fasteners exhibit superior strength-to-weight ratios and exceptional corrosion resistance compared to aluminum fasteners, making them ideal for high-stress applications. Aluminum fasteners, while lighter and more cost-effective, offer lower tensile strength and are more prone to wear and environmental degradation. The durability of titanium fasteners ensures longer service life in harsh conditions, whereas aluminum fasteners may require more frequent replacement due to fatigue and oxidation.

Corrosion Resistance Capabilities

Titanium fasteners exhibit superior corrosion resistance compared to aluminum fasteners, especially in harsh environments such as marine or chemical exposure. Their natural oxide layer provides excellent protection against oxidation and rust, ensuring long-term durability. Aluminum fasteners are more prone to corrosion, particularly in saline or acidic conditions, requiring protective coatings for enhanced resistance.

Weight and Density Factors

Titanium fasteners offer a significant advantage over aluminum fasteners due to their higher strength-to-weight ratio, making them ideal for applications requiring durability without excessive weight. While titanium has a density of approximately 4.5 g/cm3, aluminum's density is much lower at about 2.7 g/cm3, but aluminum fasteners typically require larger sizes to achieve comparable strength. This difference means titanium fasteners provide superior performance in high-stress environments with a relatively compact and lightweight design compared to bulkier aluminum fasteners.

Cost and Affordability Analysis

Titanium fasteners offer superior strength and corrosion resistance but come at a significantly higher cost compared to aluminum fasteners, which are more affordable and lightweight but less durable in harsh environments. Your choice depends on budget constraints and application requirements; aluminum fasteners are ideal for cost-sensitive projects, while titanium is better suited for high-performance, long-lasting applications. Evaluating total lifecycle costs, including maintenance and replacement, highlights that titanium fasteners, despite upfront expenses, may provide better value in demanding conditions.

Applications in Various Industries

Titanium fasteners are extensively used in aerospace, automotive, and medical industries due to their high strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for critical structural components and implants. Aluminum fasteners find wide application in electronics, consumer goods, and construction sectors where lightweight and cost-effectiveness are crucial, though they offer lower strength and corrosion resistance compared to titanium. Both materials serve distinct industrial needs, with titanium favored for demanding environments requiring durability and aluminum preferred for cost-sensitive applications with moderate requirements.

Installation and Maintenance Considerations

Titanium fasteners offer superior corrosion resistance and strength, requiring less frequent maintenance compared to aluminum fasteners, which can be prone to galvanic corrosion when exposed to certain environments. Installation of titanium fasteners may require specialized tools due to their hardness, whereas aluminum fasteners are easier to work with but can strip more easily during installation. Your choice should consider the environmental conditions and the balance between ease of installation and long-term durability needs.

Environmental Impact and Sustainability

Titanium fasteners offer superior corrosion resistance and longer lifespan, reducing the frequency of replacements and minimizing environmental waste compared to aluminum fasteners. Aluminum fasteners, while lightweight and recyclable, require more energy-intensive extraction and processing, increasing their overall carbon footprint. Choosing titanium fasteners supports your sustainability goals by promoting durability and lowering resource consumption in manufacturing and maintenance.

Choosing the Right Fastener for Your Project

Titanium fasteners offer superior strength, corrosion resistance, and lightweight properties, making them ideal for high-performance or marine applications where durability is critical. Aluminum fasteners provide excellent corrosion resistance and are significantly lighter and more cost-effective, suited for projects requiring moderate strength and weight reduction. Your choice depends on balancing budget, environmental exposure, and mechanical demands to ensure optimal performance and longevity.

titanium fasteners vs aluminum fasteners Infographic

libmatt.com

libmatt.com