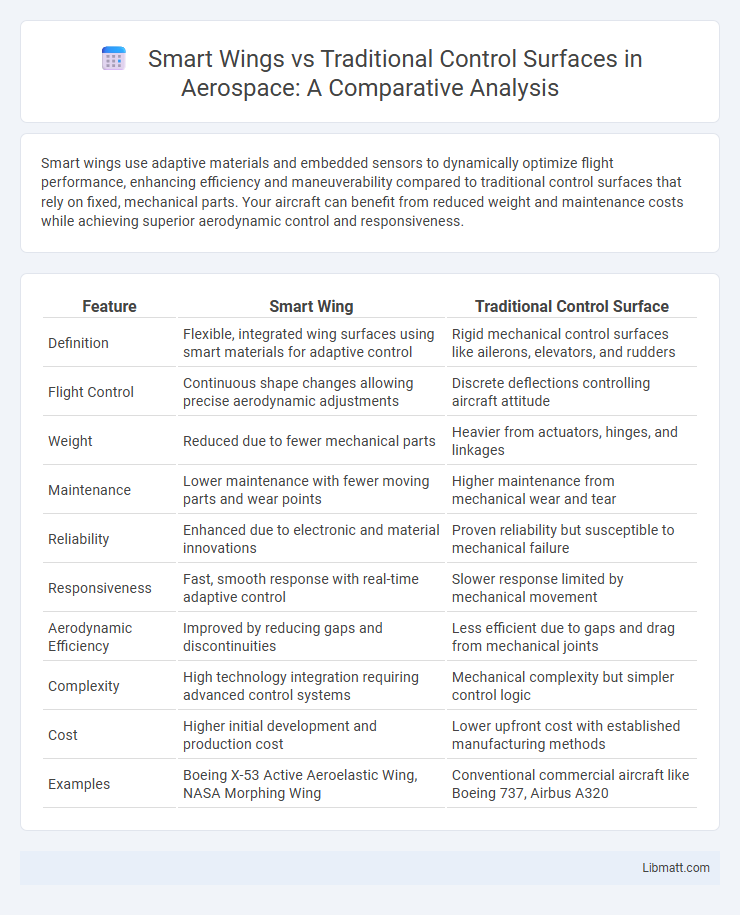

Smart wings use adaptive materials and embedded sensors to dynamically optimize flight performance, enhancing efficiency and maneuverability compared to traditional control surfaces that rely on fixed, mechanical parts. Your aircraft can benefit from reduced weight and maintenance costs while achieving superior aerodynamic control and responsiveness.

Table of Comparison

| Feature | Smart Wing | Traditional Control Surface |

|---|---|---|

| Definition | Flexible, integrated wing surfaces using smart materials for adaptive control | Rigid mechanical control surfaces like ailerons, elevators, and rudders |

| Flight Control | Continuous shape changes allowing precise aerodynamic adjustments | Discrete deflections controlling aircraft attitude |

| Weight | Reduced due to fewer mechanical parts | Heavier from actuators, hinges, and linkages |

| Maintenance | Lower maintenance with fewer moving parts and wear points | Higher maintenance from mechanical wear and tear |

| Reliability | Enhanced due to electronic and material innovations | Proven reliability but susceptible to mechanical failure |

| Responsiveness | Fast, smooth response with real-time adaptive control | Slower response limited by mechanical movement |

| Aerodynamic Efficiency | Improved by reducing gaps and discontinuities | Less efficient due to gaps and drag from mechanical joints |

| Complexity | High technology integration requiring advanced control systems | Mechanical complexity but simpler control logic |

| Cost | Higher initial development and production cost | Lower upfront cost with established manufacturing methods |

| Examples | Boeing X-53 Active Aeroelastic Wing, NASA Morphing Wing | Conventional commercial aircraft like Boeing 737, Airbus A320 |

Introduction: Smart Wing vs Traditional Control Surface

Smart wings utilize advanced materials and embedded sensors to adapt wing shape in real-time, enhancing aerodynamic efficiency and control precision. Traditional control surfaces rely on discrete, mechanical components such as ailerons, elevators, and rudders to manipulate airflow and maneuver the aircraft. Your choice between these technologies affects aircraft performance, maintenance complexity, and fuel efficiency.

Evolution of Aircraft Control Technologies

Smart wings utilize adaptive materials and embedded sensors to dynamically alter wing shape, enhancing aerodynamic efficiency and maneuverability compared to traditional control surfaces like ailerons and flaps. The evolution from mechanical linkages to electronically controlled smart wings marks a significant shift in aircraft control technologies, allowing real-time adjustments that reduce drag and improve fuel efficiency. Advances in smart wing technology integrate artificial intelligence and real-time data processing, driving the future of more responsive and efficient flight control systems.

Design Principles: Smart Wings Explained

Smart wings utilize adaptive materials and embedded sensors to continuously modify their shape, improving aerodynamic efficiency beyond the fixed configuration of traditional control surfaces. These wings incorporate real-time data processing to optimize lift, reduce drag, and enhance maneuverability without relying on mechanical hinges or actuators. Your aircraft benefits from increased fuel efficiency and smoother flight control through the dynamic responsiveness inherent in smart wing design principles.

How Traditional Control Surfaces Work

Traditional control surfaces like ailerons, elevators, and rudders physically deflect to alter the airflow around an aircraft, generating aerodynamic forces that change its attitude and direction. These surfaces rely on mechanical linkages, hinges, and actuators to transmit pilot inputs directly to the wings or tail, providing tactile feedback and precise control. Understanding how traditional control surfaces work highlights the significant differences compared to the flexible, embedded actuation of smart wing technologies in your next aircraft upgrade.

Performance Comparison: Efficiency and Responsiveness

Smart wing technology enhances aerodynamic efficiency by adapting surface shape in real-time, resulting in reduced drag and optimized lift compared to traditional control surfaces. This adaptive capability improves responsiveness, allowing finer control adjustments and faster reaction to changing flight conditions, which traditional hinged surfaces cannot match. Your aircraft benefits from smarter wings with improved fuel economy and enhanced maneuverability, delivering superior overall performance.

Impact on Aircraft Stability and Maneuverability

Smart wings enhance aircraft stability and maneuverability by using adaptive materials and real-time control inputs that optimize aerodynamic performance under varying flight conditions. Traditional control surfaces rely on fixed hinges and mechanical actuation, which can limit responsiveness and increase drag during complex maneuvers. Your aircraft can achieve smoother handling and improved fuel efficiency with smart wing technology due to its ability to dynamically adjust wing shape for optimal lift and control.

Maintenance and Reliability Considerations

Smart wings reduce maintenance frequency by integrating distributed sensors and actuators that enable real-time monitoring and adaptive control, minimizing wear and tear compared to traditional control surfaces with mechanical linkages. Reliability improves as smart wing designs reduce the number of moving parts, lowering the risk of mechanical failure and enabling predictive maintenance through data analytics. Your aircraft's operational efficiency benefits from decreased downtime and improved fault detection, enhancing overall safety and cost-effectiveness.

Integration with Modern Avionics Systems

Smart wings offer seamless integration with modern avionics systems through embedded sensors and actuators, enabling real-time data exchange and adaptive control. Unlike traditional control surfaces that rely on mechanical linkages, smart wings enhance flight efficiency and responsiveness by utilizing advanced computational algorithms directly interfaced with avionics. Your aircraft benefits from improved reliability and reduced maintenance due to the streamlined integration of smart wing technology.

Environmental and Economic Implications

Smart wings enhance aerodynamic efficiency by actively adapting to flight conditions, leading to significant reductions in fuel consumption and greenhouse gas emissions compared to traditional control surfaces. The reduction in drag and optimized lift distribution decrease operational costs for airlines due to lower fuel usage and maintenance requirements. Environmentally, smart wings contribute to noise pollution reduction and support sustainable aviation goals by minimizing the carbon footprint of aircraft throughout their lifecycle.

Future Trends in Aircraft Wing Technology

Smart wings integrate adaptive materials and embedded sensors to optimize aerodynamic performance in real-time, reducing drag and improving fuel efficiency compared to traditional control surfaces. These advanced systems enable continuous shape morphing without discrete gaps, leading to enhanced control precision and lower maintenance costs. Future aircraft designs increasingly rely on smart wing technology to achieve superior environmental sustainability and operational flexibility.

Smart wing vs Traditional control surface Infographic

libmatt.com

libmatt.com