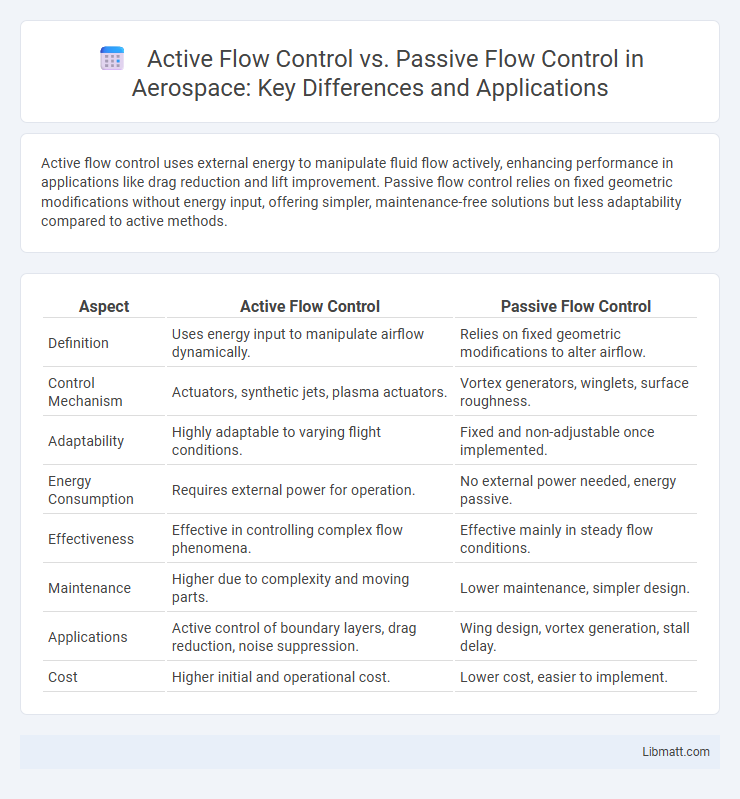

Active flow control uses external energy to manipulate fluid flow actively, enhancing performance in applications like drag reduction and lift improvement. Passive flow control relies on fixed geometric modifications without energy input, offering simpler, maintenance-free solutions but less adaptability compared to active methods.

Table of Comparison

| Aspect | Active Flow Control | Passive Flow Control |

|---|---|---|

| Definition | Uses energy input to manipulate airflow dynamically. | Relies on fixed geometric modifications to alter airflow. |

| Control Mechanism | Actuators, synthetic jets, plasma actuators. | Vortex generators, winglets, surface roughness. |

| Adaptability | Highly adaptable to varying flight conditions. | Fixed and non-adjustable once implemented. |

| Energy Consumption | Requires external power for operation. | No external power needed, energy passive. |

| Effectiveness | Effective in controlling complex flow phenomena. | Effective mainly in steady flow conditions. |

| Maintenance | Higher due to complexity and moving parts. | Lower maintenance, simpler design. |

| Applications | Active control of boundary layers, drag reduction, noise suppression. | Wing design, vortex generation, stall delay. |

| Cost | Higher initial and operational cost. | Lower cost, easier to implement. |

Introduction to Flow Control in Fluid Dynamics

Flow control in fluid dynamics involves manipulating fluid motion to enhance performance or reduce resistance. Active flow control uses energy input through devices like actuators or synthetic jets to dynamically alter flow behavior, offering adaptability for varying conditions. Your choice between active and passive methods depends on factors such as energy availability, system complexity, and desired control precision.

Definitions: Active vs Passive Flow Control

Active flow control involves the deliberate manipulation of fluid dynamics using external energy sources such as actuators, jets, or synthetic jets to influence flow behavior, reduce drag, or delay flow separation. Passive flow control relies on fixed geometric modifications or surface treatments like vortex generators, riblets, or turbulators that do not require external energy input but alter flow characteristics through their inherent design. Both techniques aim to optimize aerodynamic performance, with active methods offering adaptability and control while passive methods provide simplicity and reliability.

Mechanisms of Active Flow Control

Active flow control mechanisms manipulate fluid flow using external energy sources such as actuators, synthetic jets, or plasma actuators to actively modify boundary layer characteristics and reduce turbulence. These techniques improve aerodynamic performance by dynamically responding to changing flow conditions, enabling control over separation and drag reduction. Your system's efficiency can be significantly enhanced through precise tuning of active flow control strategies tailored to specific operational environments.

Key Principles of Passive Flow Control

Passive flow control relies on fixed devices such as vortex generators, riblets, and surface textures that manipulate airflow without external energy input. These elements alter the boundary layer behavior by promoting turbulence or delaying flow separation, thereby reducing drag and enhancing stability. You benefit from simpler implementation and lower maintenance compared to active systems, though with less adaptability to varying conditions.

Advantages of Active Flow Control Systems

Active flow control systems offer precise manipulation of aerodynamic properties by dynamically adjusting control inputs such as jets, synthetic jets, or plasma actuators, leading to improved lift, reduced drag, and enhanced maneuverability. These systems adapt to varying flight conditions in real-time, providing greater efficiency and fuel savings compared to passive flow control methods, which rely on fixed structures or surface modifications. The ability to modulate flow characteristics actively results in superior performance optimization and noise reduction in aerospace applications.

Benefits and Limitations of Passive Flow Control

Passive flow control offers benefits such as simplicity, reliability, and no energy consumption, making it cost-effective and low-maintenance for aerodynamic applications. Its limitations include less adaptability to changing flow conditions and lower effectiveness in turbulent or complex flow environments compared to active flow control techniques. Understanding these trade-offs helps you choose the most suitable method for optimizing fluid dynamics in your specific engineering project.

Common Applications in Aerospace and Automotive Industries

Active flow control techniques, such as synthetic jets and plasma actuators, are commonly used in aerospace to enhance lift, reduce drag, and control boundary layer separation on aircraft wings and turbine blades. Passive flow control methods, including vortex generators and riblets, find wide application in automotive industries to improve fuel efficiency and vehicle stability by managing airflow over car bodies and reducing aerodynamic drag. The aerospace sector prioritizes active systems for dynamic conditions, while automotive design often favors passive solutions for their simplicity and reliability.

Performance Comparison: Efficiency and Effectiveness

Active flow control systems demonstrate superior efficiency by dynamically adjusting to varying flow conditions, resulting in enhanced lift, reduced drag, and optimized energy consumption compared to passive flow control methods. Passive flow control relies on fixed geometries such as vortex generators and riblets, offering simplicity and reliability but limited adaptability and overall aerodynamic improvement. Studies reveal active flow control can achieve up to 20-30% greater performance enhancement in terms of fuel efficiency and flow stability, especially in complex or changing aerodynamic environments.

Challenges and Future Trends in Flow Control

Active flow control faces challenges such as energy consumption, system complexity, and real-time adaptability, limiting widespread implementation in aerospace and automotive applications. Passive flow control offers simpler integration and reliability but struggles with limited effectiveness and adaptability across varying flow conditions. Future trends emphasize hybrid systems combining active and passive methods, leveraging advanced sensors and AI to optimize Your flow control systems for enhanced efficiency and reduced drag.

Conclusion: Choosing Between Active and Passive Flow Control

Choosing between active and passive flow control depends on factors such as energy consumption, complexity, and application requirements. Active flow control offers precise manipulation of fluid dynamics with adjustable input but requires power and maintenance, while passive flow control relies on fixed structures with no energy input, providing simplicity and durability. Your decision hinges on balancing efficiency, cost, and performance goals for optimal fluid management.

Active flow control vs Passive flow control Infographic

libmatt.com

libmatt.com