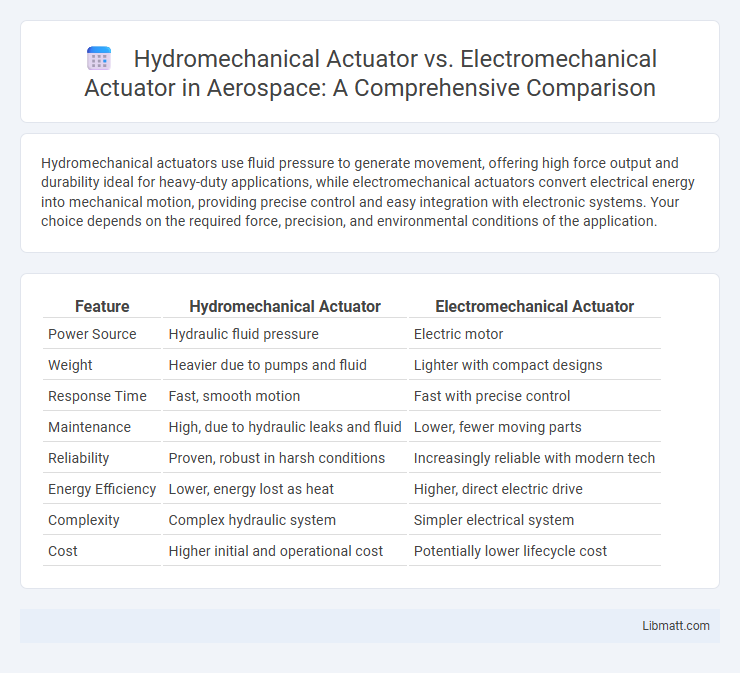

Hydromechanical actuators use fluid pressure to generate movement, offering high force output and durability ideal for heavy-duty applications, while electromechanical actuators convert electrical energy into mechanical motion, providing precise control and easy integration with electronic systems. Your choice depends on the required force, precision, and environmental conditions of the application.

Table of Comparison

| Feature | Hydromechanical Actuator | Electromechanical Actuator |

|---|---|---|

| Power Source | Hydraulic fluid pressure | Electric motor |

| Weight | Heavier due to pumps and fluid | Lighter with compact designs |

| Response Time | Fast, smooth motion | Fast with precise control |

| Maintenance | High, due to hydraulic leaks and fluid | Lower, fewer moving parts |

| Reliability | Proven, robust in harsh conditions | Increasingly reliable with modern tech |

| Energy Efficiency | Lower, energy lost as heat | Higher, direct electric drive |

| Complexity | Complex hydraulic system | Simpler electrical system |

| Cost | Higher initial and operational cost | Potentially lower lifecycle cost |

Overview of Hydromechanical and Electromechanical Actuators

Hydromechanical actuators use fluid pressure to generate mechanical motion, offering high force density and precise control in heavy-duty applications such as aerospace and industrial machinery. Electromechanical actuators convert electrical energy into mechanical movement using motors and gears, providing cleaner, more efficient operation with easier integration into electronic control systems. Your choice between these actuators depends on the power requirements, response speed, and system complexity needed for your application.

Working Principles: Hydromechanical vs Electromechanical

Hydromechanical actuators operate by converting hydraulic fluid pressure into mechanical motion, utilizing pistons, gears, or motors driven by fluid flow to generate force and movement. Electromechanical actuators function by converting electrical energy into mechanical motion through electric motors, solenoids, or screw drives, providing precise control and positioning. Hydromechanical systems excel in high-force applications with smooth, continuous motion, while electromechanical actuators offer compact design and energy efficiency with rapid response times.

Key Components of Each Actuator Type

Hydromechanical actuators primarily consist of components such as a hydraulic pump, fluid reservoir, control valves, and pistons or cylinders that convert fluid pressure into mechanical motion. Electromechanical actuators include electric motors, gearboxes, sensors, and electronic controllers that manage precise movement through electrical energy conversion. Understanding the key components helps you select the ideal actuator based on application requirements for power, precision, and control.

Performance Comparison: Speed, Precision, and Force

Hydromechanical actuators typically deliver higher force output and smoother operation due to fluid power, enabling rapid responses in heavy-duty applications, while electromechanical actuators excel in precision and repeatability with minimal maintenance requirements. Speed in hydromechanical systems can be adjusted via fluid flow rates, often surpassing electromechanical actuators in raw power, but at the cost of complexity and potential leakage issues. Electromechanical actuators provide superior control resolution and energy efficiency, making them ideal for applications demanding high precision and moderate force.

Energy Efficiency and Power Consumption

Hydromechanical actuators typically consume more energy due to hydraulic pump operation and fluid losses, resulting in lower overall efficiency compared to electromechanical actuators. Electromechanical actuators convert electrical energy directly into mechanical motion with minimal losses, making them more energy-efficient and cost-effective for many applications. If you prioritize reducing power consumption, electromechanical actuators are often the better choice for maximizing efficiency in modern systems.

Maintenance and Reliability Considerations

Hydromechanical actuators require regular maintenance due to fluid leakage, contamination, and seal wear, impacting long-term reliability and operational costs. Electromechanical actuators offer higher reliability with fewer maintenance needs, as they lack hydraulic fluid and associated components prone to wear and leakage. Your choice depends on application demands, with electromechanical actuators favored for low-maintenance environments and hydromechanical actuators suited for high-force, heavy-duty conditions.

Application Areas: Industry and Aerospace

Hydromechanical actuators are extensively utilized in heavy industry and aerospace applications requiring high force and durability, such as aircraft flight control systems and industrial machinery automation. Electromechanical actuators dominate precision tasks in aerospace, including satellite positioning and aircraft cabin components, due to their accuracy and ease of integration with digital control systems. Both actuator types serve critical roles, with hydromechanical units favored for power-intensive environments and electromechanical units preferred for lightweight, high-precision operations.

Control Systems Integration

Hydromechanical actuators offer robust force output and high power density, making them suitable for heavy-duty control systems integration in aerospace and industrial machinery. Electromechanical actuators provide precise position control and easier interfacing with digital control systems through direct electrical inputs, enhancing responsiveness and programmability. Integration of hydromechanical systems demands complex fluid power management, while electromechanical systems benefit from simpler wiring and compatibility with advanced sensor feedback loops.

Cost Analysis: Initial Investment and Lifecycle

Hydromechanical actuators typically require a higher initial investment due to complex hydraulic components and robust materials, while electromechanical actuators often offer lower upfront costs with simpler assembly. Your choice impacts lifecycle expenses as hydromechanical systems demand regular maintenance, fluid replacements, and potential leakage repairs, increasing long-term operational costs. Electromechanical actuators, benefiting from fewer moving parts and cleaner operation, generally incur lower maintenance expenses and longer service intervals, optimizing total cost of ownership.

Future Trends in Actuator Technology

Future trends in actuator technology emphasize increased efficiency and precision with hybrid systems combining hydromechanical and electromechanical actuators to leverage advantages of both. Advances in smart materials and embedded sensors are driving improved performance, real-time monitoring, and predictive maintenance capabilities. Integration with IoT and AI enables adaptive control algorithms, optimizing actuator responses in aerospace, robotics, and automotive sectors.

hydromechanical actuator vs electromechanical actuator Infographic

libmatt.com

libmatt.com