Circumferential frames provide structural support around the perimeter of a vessel, maintaining its shape and resisting external pressure, while longitudinal stringers run parallel to the vessel's length, offering increased strength against bending and twisting forces. Understanding the distinct roles of these components is essential to ensure your vessel's structural integrity and stability.

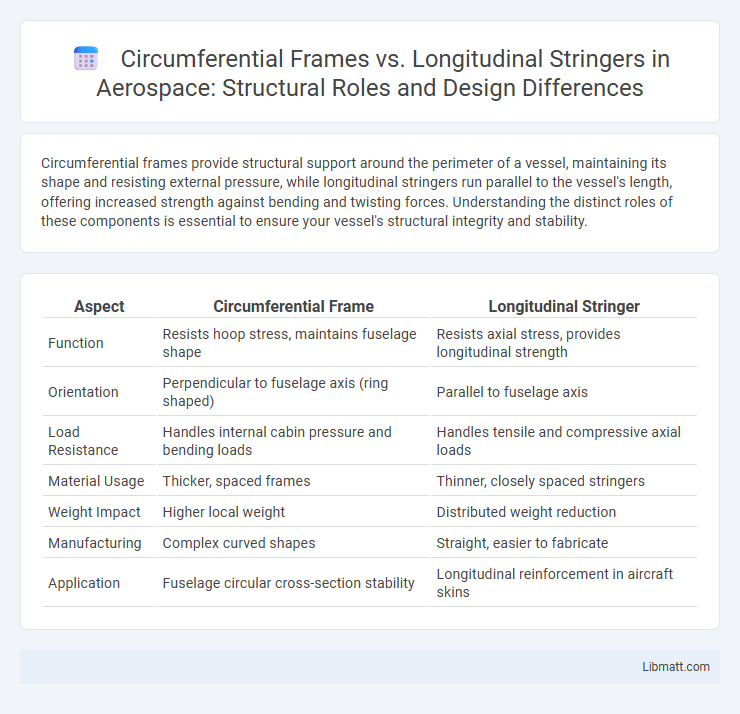

Table of Comparison

| Aspect | Circumferential Frame | Longitudinal Stringer |

|---|---|---|

| Function | Resists hoop stress, maintains fuselage shape | Resists axial stress, provides longitudinal strength |

| Orientation | Perpendicular to fuselage axis (ring shaped) | Parallel to fuselage axis |

| Load Resistance | Handles internal cabin pressure and bending loads | Handles tensile and compressive axial loads |

| Material Usage | Thicker, spaced frames | Thinner, closely spaced stringers |

| Weight Impact | Higher local weight | Distributed weight reduction |

| Manufacturing | Complex curved shapes | Straight, easier to fabricate |

| Application | Fuselage circular cross-section stability | Longitudinal reinforcement in aircraft skins |

Introduction to Circumferential Frames and Longitudinal Stringers

Circumferential frames are structural components that encircle the hull of a ship, providing transverse strength and maintaining the vessel's shape under external pressure. Longitudinal stringers run parallel to the ship's length, enhancing longitudinal strength and distributing bending stresses along the hull. Both elements work synergistically to reinforce a ship's structural integrity and improve load-bearing capacity.

Structural Roles in Aerospace Engineering

Circumferential frames provide essential radial support to maintain the fuselage's shape and resist hoop stresses, crucial for pressurization loads in aerospace structures. Longitudinal stringers run parallel to the fuselage axis, enhancing axial stiffness and carrying bending loads during flight maneuvers. Together, these structural elements distribute stresses efficiently, optimizing the load-bearing capacity and structural integrity of aircraft fuselages.

Design Principles: Frames vs. Stringers

Circumferential frames provide transverse strength by resisting radial loads and maintaining the hull's shape under pressure, crucial in ship and aircraft fuselage design. Longitudinal stringers run parallel to the vessel's or aircraft's axis, offering longitudinal stiffness and distributing bending stresses along the length. Combining frames and stringers optimizes structural integrity by balancing load resistance in both transverse and longitudinal directions, enhancing overall durability and performance.

Load Distribution and Strength Analysis

Circumferential frames primarily resist hoop stresses and provide lateral support, effectively distributing loads around the vessel's circumference to maintain structural integrity under external pressure. Longitudinal stringers run parallel to the ship's length, enhancing longitudinal strength by distributing bending moments and shear forces along the hull, crucial for handling wave-induced stresses. Combining circumferential frames with longitudinal stringers creates an optimized structural grid that balances load distribution, improves stiffness, and maximizes overall strength in ship design.

Weight Implications and Material Efficiency

Circumferential frames distribute loads around the fuselage perimeter, providing enhanced structural integrity while enabling thinner skin panels, which reduces overall weight and improves material efficiency. Longitudinal stringers run parallel to the aircraft's axis, supporting skin panels against bending and buckling, but often require additional reinforcements, increasing weight. Optimizing the balance between circumferential frames and longitudinal stringers is critical for minimizing structural weight while maximizing material utilization in aerospace design.

Manufacturing Techniques and Challenges

Circumferential frames require precise bending and welding techniques to maintain structural integrity and exact curvature, often involving complex jigs and specialized machinery. Longitudinal stringers demand consistent extrusion or rolling processes to achieve uniform cross-sections and must withstand tensile forces along the vessel's length during manufacturing. Your choice between these structural supports significantly impacts fabrication time, cost, and the level of skilled labor needed to address distortion or alignment challenges.

Maintenance and Repair Considerations

Circumferential frames provide enhanced structural rigidity, making damage localized and often easier to repair without affecting adjacent sections, which benefits maintenance efficiency. Longitudinal stringers require careful inspection along their length due to stress distribution, and repairs can be more complex as damage may impact larger portions of the structure. Your maintenance strategy should consider the ease of accessing and replacing components based on the frame type to optimize repair time and costs.

Cost Comparisons and Production Scalability

Circumferential frames generally incur higher initial costs due to increased material usage and complex fabrication processes, while longitudinal stringers offer cost efficiency through simpler design and reduced weight. Production scalability favors longitudinal stringers, as their modular components enable faster assembly and easier automation, lowering labor expenses. Your choice impacts overall budget and manufacturing speed, with stringers often preferred for large-scale production runs seeking cost-effective solutions.

Application Examples in Modern Aircraft

Circumferential frames are commonly implemented in commercial airliners like the Boeing 777 and Airbus A350 to provide structural integrity and resist hoop stresses in the fuselage. Longitudinal stringers are prominently used in military aircraft such as the F-35 Lightning II and commercial jets to enhance fuselage stiffness and reduce bending under aerodynamic loads. Both framing methods are critical for optimizing weight distribution and ensuring the durability of modern aircraft structures.

Future Trends in Airframe Structure Design

Circumferential frames and longitudinal stringers will evolve to enhance lightweight and highly durable airframes by integrating advanced composites and additive manufacturing techniques. Emerging designs prioritize optimized load distribution and damage tolerance, with circumferential frames improving fuselage stiffness while longitudinal stringers enhance overall structural integrity. Your aircraft's future airframe could leverage hybrid structures combining these elements for superior performance and fuel efficiency.

circumferential frame vs longitudinal stringer Infographic

libmatt.com

libmatt.com