Strut-braced wings use external supports to reduce structural weight and increase wing strength, enhancing fuel efficiency and payload capacity for your aircraft. Cantilever wings rely solely on internal spars and ribs, offering a cleaner aerodynamic profile and reduced drag, which can improve speed and maneuverability.

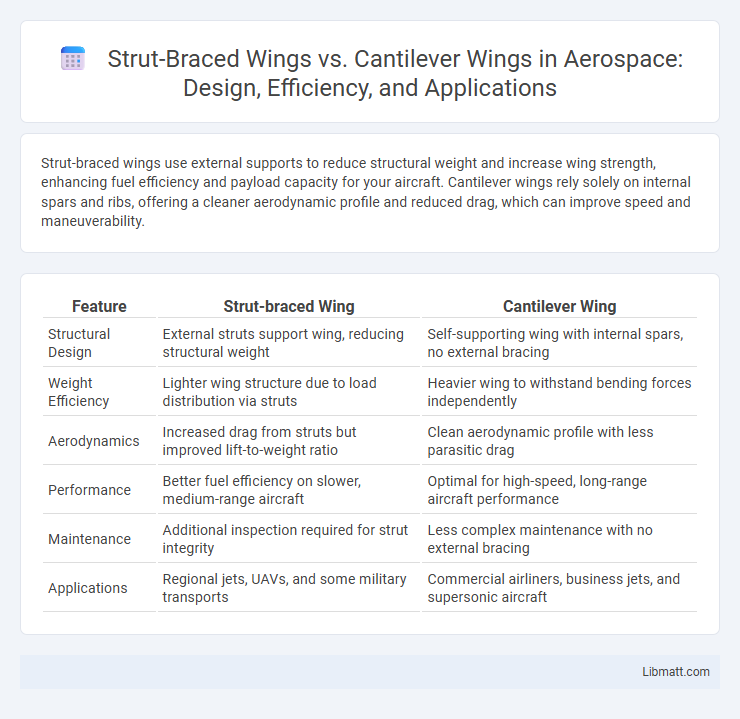

Table of Comparison

| Feature | Strut-braced Wing | Cantilever Wing |

|---|---|---|

| Structural Design | External struts support wing, reducing structural weight | Self-supporting wing with internal spars, no external bracing |

| Weight Efficiency | Lighter wing structure due to load distribution via struts | Heavier wing to withstand bending forces independently |

| Aerodynamics | Increased drag from struts but improved lift-to-weight ratio | Clean aerodynamic profile with less parasitic drag |

| Performance | Better fuel efficiency on slower, medium-range aircraft | Optimal for high-speed, long-range aircraft performance |

| Maintenance | Additional inspection required for strut integrity | Less complex maintenance with no external bracing |

| Applications | Regional jets, UAVs, and some military transports | Commercial airliners, business jets, and supersonic aircraft |

Introduction to Wing Design: Strut-Braced vs Cantilever

Strut-braced wings employ external supports to transfer aerodynamic loads, enabling lighter structures and improved fuel efficiency for certain aircraft sizes. Cantilever wings rely on internal spars and reinforcements without external braces, providing cleaner aerodynamics and reduced drag. Your choice between these designs affects aircraft performance, structural weight, and maintenance complexity.

Fundamental Principles of Strut-Braced Wings

Strut-braced wings utilize external supports, or struts, that connect the wing to the fuselage or landing gear, enabling a lighter and thinner wing structure by distributing aerodynamic loads more efficiently. This design reduces bending moments at the wing root, allowing increased wingspan and improved lift-to-drag ratio without excessive structural weight. Your aircraft benefits from enhanced fuel efficiency and extended range by leveraging these fundamental principles of strut-braced wings.

Key Characteristics of Cantilever Wings

Cantilever wings are free-standing structures with no external bracing, relying on internal spars and ribs to support aerodynamic loads, resulting in a sleek, low-drag profile that enhances aircraft performance. This design allows for greater structural integrity and smoother airflow, making cantilever wings ideal for high-speed and modern aircraft. Your choice of wing type impacts factors such as maintenance complexity and fuel efficiency, with cantilever wings offering a cleaner aerodynamic solution compared to strut-braced wings.

Structural Efficiency and Weight Considerations

Strut-braced wings offer enhanced structural efficiency by transferring aerodynamic loads through external supports, allowing for lighter wing structures and reduced material use compared to cantilever wings, which rely solely on internal spars and ribs to bear all stresses. This external bracing in strut-braced designs leads to lower wing weight and improved fuel efficiency, especially beneficial for high-aspect-ratio wings used in gliders and some light aircraft. Your choice between these wing types should consider trade-offs in aerodynamic drag versus structural weight to optimize overall aircraft performance.

Aerodynamic Performance Comparison

Strut-braced wings offer reduced structural weight by transferring loads through external supports, improving lift-to-drag ratios at lower speeds but adding parasitic drag from the struts themselves. Cantilever wings, free from external bracing, achieve cleaner aerodynamics with lower drag profiles, enhancing high-speed performance and fuel efficiency. Your choice between these wing types depends on the balance between structural efficiency and aerodynamic cleanliness tailored to specific flight regimes.

Impact on Fuel Efficiency and Range

Strut-braced wings reduce structural weight by distributing aerodynamic loads through external supports, resulting in improved fuel efficiency and longer range due to decreased drag and lower fuel consumption. Cantilever wings, while structurally cleaner, typically require heavier internal spars that increase overall aircraft weight, negatively impacting fuel efficiency and range. Aircraft with strut-braced wings often achieve better lift-to-drag ratios, optimizing aerodynamic performance and extending flight distances compared to cantilever-wing designs.

Maintenance and Durability Aspects

Strut-braced wings generally offer easier maintenance due to the external support structures simplifying inspection and repair compared to cantilever wings, which rely on internal spars and require more complex access. Durability of strut-braced wings benefits from load distribution through struts, reducing stress on the wing root, while cantilever wings need robust internal reinforcement to withstand aerodynamic forces independently. Your choice between the two should consider maintenance capabilities and long-term durability demands of your aircraft operations.

Application in Modern Aircraft Designs

Strut-braced wings are commonly utilized in light aircraft and regional planes to reduce structural weight and enable longer wingspans, enhancing fuel efficiency and low-speed performance. Cantilever wings dominate commercial airliners and military jets due to their clean aerodynamic profile and ability to support higher loads without external supports, improving speed and maneuverability. Modern hybrid designs explore integrating strut-bracing for UAVs and electric vertical takeoff and landing (eVTOL) aircraft to balance structural integrity with aerodynamic efficiency.

Future Trends in Wing Architecture

Strut-braced wings are gaining renewed interest due to their ability to reduce structural weight and improve fuel efficiency by supporting longer, thinner wings suitable for next-generation aircraft. Cantilever wings remain popular for their clean aerodynamic design and ease of maintenance, but advancements in materials and computational design are driving innovations that blur the lines between these architectures. Your choice in wing design will depend on optimizing performance and sustainability goals as future trends emphasize lightweight structures and environmental impact reduction.

Conclusion: Choosing Between Strut-Braced and Cantilever Wings

Strut-braced wings offer structural weight savings and increased lift efficiency, making them ideal for fuel-efficient, long-range designs, while cantilever wings provide cleaner aerodynamics with fewer drag-inducing components, benefiting higher-speed performance. Your choice depends on mission priorities: prioritize strut-braced wings for maximizing fuel economy and payload or select cantilever wings for sleek profiles and reduced maintenance complexity. Both wing types balance trade-offs in weight, drag, and structural design to optimize aircraft performance based on specific operational needs.

Strut-braced Wing vs Cantilever Wing Infographic

libmatt.com

libmatt.com