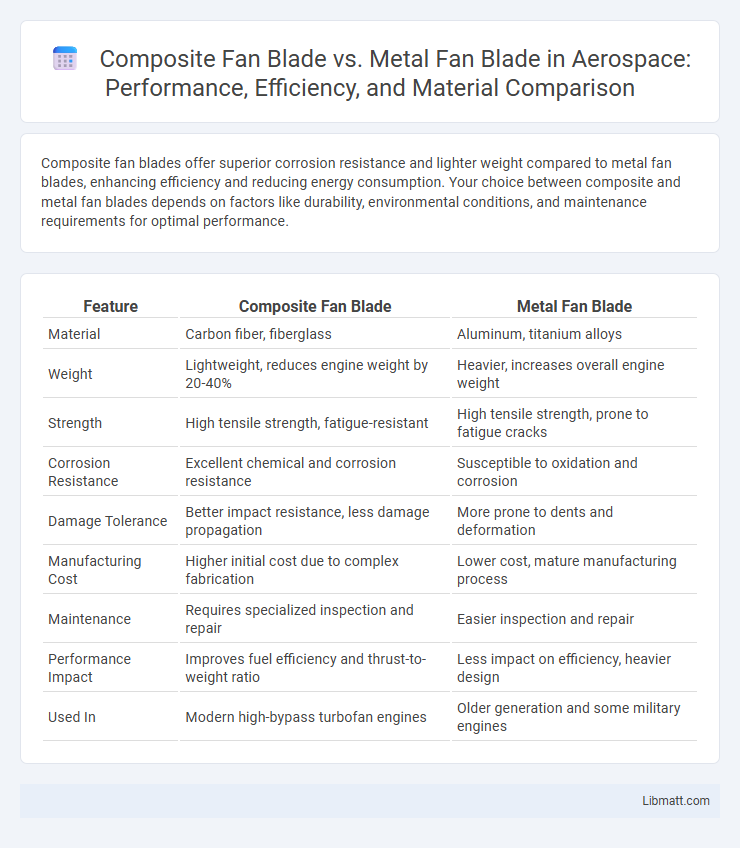

Composite fan blades offer superior corrosion resistance and lighter weight compared to metal fan blades, enhancing efficiency and reducing energy consumption. Your choice between composite and metal fan blades depends on factors like durability, environmental conditions, and maintenance requirements for optimal performance.

Table of Comparison

| Feature | Composite Fan Blade | Metal Fan Blade |

|---|---|---|

| Material | Carbon fiber, fiberglass | Aluminum, titanium alloys |

| Weight | Lightweight, reduces engine weight by 20-40% | Heavier, increases overall engine weight |

| Strength | High tensile strength, fatigue-resistant | High tensile strength, prone to fatigue cracks |

| Corrosion Resistance | Excellent chemical and corrosion resistance | Susceptible to oxidation and corrosion |

| Damage Tolerance | Better impact resistance, less damage propagation | More prone to dents and deformation |

| Manufacturing Cost | Higher initial cost due to complex fabrication | Lower cost, mature manufacturing process |

| Maintenance | Requires specialized inspection and repair | Easier inspection and repair |

| Performance Impact | Improves fuel efficiency and thrust-to-weight ratio | Less impact on efficiency, heavier design |

| Used In | Modern high-bypass turbofan engines | Older generation and some military engines |

Introduction to Fan Blades: Composite vs Metal

Composite fan blades are constructed from advanced polymers reinforced with materials like carbon fiber or fiberglass, offering high strength-to-weight ratios and corrosion resistance. Metal fan blades, typically made from aluminum or steel, provide robust structural integrity and durability but are heavier and prone to corrosion over time. The choice between composite and metal fan blades impacts performance, maintenance, and efficiency in various industrial and aerospace applications.

Material Composition and Manufacturing

Composite fan blades consist of advanced materials like carbon fiber reinforced polymers or fiberglass, offering high strength-to-weight ratios and resistance to corrosion and fatigue. Metal fan blades, typically made from aluminum or titanium alloys, provide excellent durability and thermal stability but are heavier and more susceptible to stress-related wear. The manufacturing process for composite blades involves layering and curing fibers in resin matrices, enabling aerodynamic customization, while metal blades are produced through casting, forging, or machining, emphasizing structural integrity and precision.

Weight and Structural Differences

Composite fan blades weigh significantly less than metal fan blades due to their advanced fiber-reinforced materials, enhancing fuel efficiency and reducing engine stress. Structurally, composite blades offer superior flexibility and fatigue resistance, allowing them to absorb impacts better than rigid metal blades. Metal blades, while heavier and prone to corrosion, provide higher thermal resistance and structural rigidity under extreme operational conditions.

Performance and Efficiency Comparison

Composite fan blades offer superior performance and efficiency by reducing weight and enhancing aerodynamic properties, resulting in lower energy consumption and quieter operation compared to metal fan blades. Metal fan blades provide durability and strength but often suffer from increased inertia, leading to higher power requirements and potential vibration issues. Choosing composite fan blades can improve your system's overall energy efficiency and operational lifespan while maintaining reliable airflow performance.

Durability and Lifespan

Composite fan blades offer superior durability due to their high resistance to corrosion, fatigue, and impact, resulting in longer service life compared to traditional metal fan blades. Metal fan blades, while strong, are more susceptible to corrosion and fatigue over time, especially in harsh environments, which can reduce their operational lifespan. Advances in composite materials like carbon fiber and fiberglass have enhanced blade longevity, making composites the preferred choice for applications requiring extended durability and low maintenance.

Cost Analysis and Maintenance

Composite fan blades typically offer lower upfront costs due to less expensive raw materials and manufacturing processes compared to metal fan blades. Maintenance expenses for composite blades are generally reduced because of their corrosion resistance and lighter weight, which decreases wear on bearings and related components. Metal fan blades, while more durable in extreme conditions, often require more frequent inspections, balancing, and potential repairs, leading to higher long-term maintenance costs.

Safety and Failure Modes

Composite fan blades offer superior resistance to fatigue and corrosion compared to metal fan blades, enhancing safety by reducing the risk of crack propagation and structural failure during high-stress operations. Metal fan blades are prone to stress corrosion cracking and can experience sudden brittle fractures, which pose significant safety hazards in aviation and industrial applications. The failure modes of composite blades typically involve delamination or fiber breakage, which tend to be more gradual and detectable, while metal blades often fail abruptly without warning signs.

Applications in Aerospace and Industry

Composite fan blades offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace applications where weight reduction and fuel efficiency are critical. Metal fan blades, typically made from titanium or aluminum alloys, provide exceptional durability and thermal resistance, favoring heavy-duty industrial uses such as power generation and ventilation systems. The choice between composite and metal fan blades depends on operating conditions, with composites preferred in high-performance aircraft engines and metals favored in harsh industrial environments.

Environmental Impact and Sustainability

Composite fan blades offer a lower environmental impact and better sustainability compared to metal fan blades due to their lighter weight, which reduces energy consumption during operation and transportation. The manufacturing process of composite materials typically generates fewer carbon emissions and allows for easier recycling and reuse, contributing to resource conservation. Your choice of composite fan blades supports long-term environmental responsibility by minimizing carbon footprint and promoting sustainable material use.

Future Trends in Fan Blade Technology

Composite fan blades are increasingly favored in future fan blade technology for their lightweight properties and superior corrosion resistance, enabling improved energy efficiency and reduced maintenance costs. Metal fan blades, while robust and traditionally used, face challenges in weight and susceptibility to environmental degradation, prompting a shift towards composite materials in aerospace and industrial applications. Your choice will likely lean towards composites as manufacturers prioritize sustainability, durability, and performance advancements in blade design.

Composite Fan Blade vs Metal Fan Blade Infographic

libmatt.com

libmatt.com