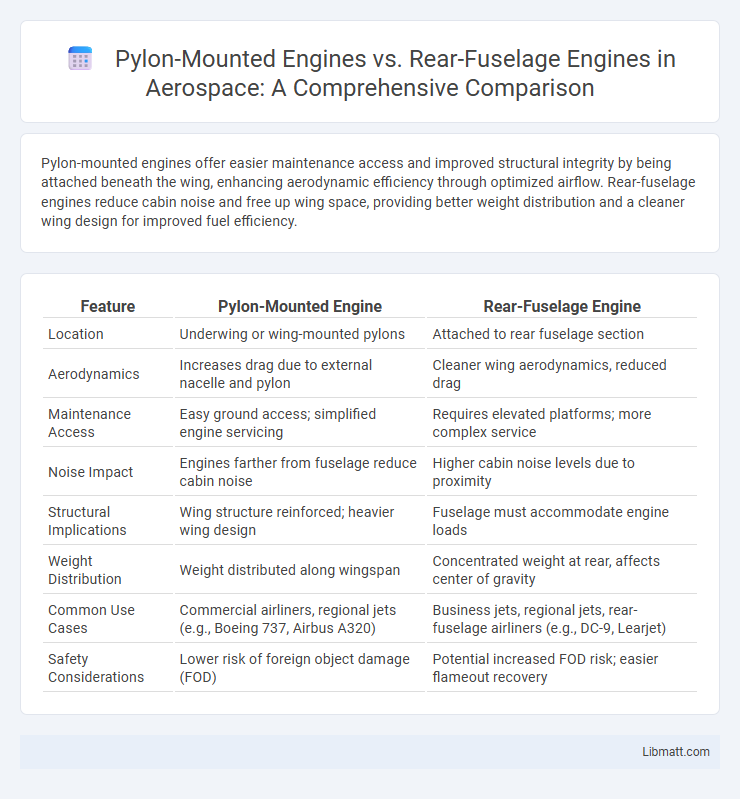

Pylon-mounted engines offer easier maintenance access and improved structural integrity by being attached beneath the wing, enhancing aerodynamic efficiency through optimized airflow. Rear-fuselage engines reduce cabin noise and free up wing space, providing better weight distribution and a cleaner wing design for improved fuel efficiency.

Table of Comparison

| Feature | Pylon-Mounted Engine | Rear-Fuselage Engine |

|---|---|---|

| Location | Underwing or wing-mounted pylons | Attached to rear fuselage section |

| Aerodynamics | Increases drag due to external nacelle and pylon | Cleaner wing aerodynamics, reduced drag |

| Maintenance Access | Easy ground access; simplified engine servicing | Requires elevated platforms; more complex service |

| Noise Impact | Engines farther from fuselage reduce cabin noise | Higher cabin noise levels due to proximity |

| Structural Implications | Wing structure reinforced; heavier wing design | Fuselage must accommodate engine loads |

| Weight Distribution | Weight distributed along wingspan | Concentrated weight at rear, affects center of gravity |

| Common Use Cases | Commercial airliners, regional jets (e.g., Boeing 737, Airbus A320) | Business jets, regional jets, rear-fuselage airliners (e.g., DC-9, Learjet) |

| Safety Considerations | Lower risk of foreign object damage (FOD) | Potential increased FOD risk; easier flameout recovery |

Introduction to Engine Placement in Aircraft

Pylon-mounted engines are typically attached beneath the wings, offering improved aerodynamics and easier maintenance access, while rear-fuselage engines are integrated into the aircraft's tail section, enhancing cabin noise reduction and aerodynamic efficiency. The choice between pylon-mounted and rear-fuselage engines significantly influences aircraft performance, fuel efficiency, and structural design. Engine placement impacts weight distribution, center of gravity, and ground clearance, crucial factors in overall aircraft stability and operational safety.

Overview of Pylon-Mounted Engines

Pylon-mounted engines are positioned beneath the aircraft wings, attached via support structures called pylons, which optimize aerodynamic efficiency and facilitate maintenance access. This configuration enhances aircraft stability by distributing engine weight closer to the wing's center of lift, improving fuel efficiency and reducing noise inside the cabin. Pylon-mounted engines are prevalent in commercial airliners such as the Boeing 737 and Airbus A320, demonstrating reliability and operational effectiveness in various flight conditions.

Overview of Rear-Fuselage Engines

Rear-fuselage engines are integrated into the tail section of an aircraft, offering aerodynamic benefits by reducing drag and enhancing fuel efficiency. This configuration minimizes noise levels in the cabin and allows for a cleaner wing design, improving lift and stability. Your choice between pylon-mounted and rear-fuselage engines will impact maintenance accessibility and aircraft weight distribution.

Aerodynamic Implications of Engine Location

Pylon-mounted engines generate increased aerodynamic drag due to interference effects between the nacelle and wing, potentially reducing overall lift-to-drag ratio compared to rear-fuselage engines. Rear-fuselage engines minimize wing structural weight and drag by concentrating propulsion mass aft, leading to cleaner wing aerodynamics and improved boundary layer behavior. Engine location also influences aircraft stability and control, with pylon mounts typically affecting wing bending moments, while rear-fuselage mounts alter tailplane effectiveness and yaw characteristics.

Maintenance and Accessibility Considerations

Pylon-mounted engines offer superior maintenance accessibility by being positioned away from the fuselage, allowing easier inspection, repairs, and part replacements without extensive disassembly. Rear-fuselage engines, while aerodynamically efficient, often present challenges for technicians due to their compact location, requiring specialized equipment and longer downtimes for maintenance tasks. Understanding these accessibility differences helps you optimize operational efficiency and reduce aircraft turnaround times.

Impact on Aircraft Performance and Efficiency

Pylon-mounted engines typically improve aircraft aerodynamic efficiency by positioning engines away from the fuselage, reducing interference drag and enhancing thrust distribution. Rear-fuselage engines contribute to a quieter cabin environment and lower wing structural weight but may increase drag due to fuselage boundary layer interactions. Engine placement impacts fuel efficiency, climb performance, and maintenance accessibility, making the choice critical for optimizing overall aircraft performance.

Noise and Vibration Differences

Pylon-mounted engines generate higher noise and vibration levels within the cabin due to their proximity to the wing structure, which transmits engine vibrations more directly. Rear-fuselage engine placements offer reduced cabin noise and smoother ride experiences by isolating engine vibrations away from the main fuselage and passenger area. Your comfort is enhanced with rear-fuselage engines, as their layout minimizes both airborne noise and structural vibrations compared to pylon-mounted configurations.

Safety and Emergency Factors

Pylon-mounted engines offer improved safety by enhancing structural separation from the fuselage, reducing the risk of fire or debris impact in emergencies. Rear-fuselage engines concentrate risk near the cabin, potentially increasing vulnerability during engine failure or fire incidents. Emergency evacuation procedures can be more straightforward with pylon-mounted designs due to clearer access paths and less heat exposure near passenger areas.

Influence on Aircraft Design and Configuration

Pylon-mounted engines, typically located beneath the wings, influence aircraft design by allowing easier access for maintenance and improved wing aerodynamics, contributing to better fuel efficiency and structural balance. Rear-fuselage engines reduce wing structural stress and improve cabin noise levels but require reinforced aft fuselage design, impacting overall aircraft weight and center of gravity. Your choice between these configurations directly affects aircraft stability, maintenance logistics, and aerodynamic performance.

Future Trends in Aircraft Engine Placement

Emerging trends in aircraft engine placement emphasize improved aerodynamics and fuel efficiency, with pylon-mounted engines offering easier maintenance access and noise reduction through optimized nacelle design. Rear-fuselage engines contribute to enhanced cabin comfort by isolating engine noise and enabling quieter flight profiles, appealing to next-generation regional jets and business aircraft. Your choice will depend on balancing operational efficiency, environmental regulations, and advances in composite materials enabling innovative integration methods.

Pylon-mounted engine vs Rear-fuselage engine Infographic

libmatt.com

libmatt.com