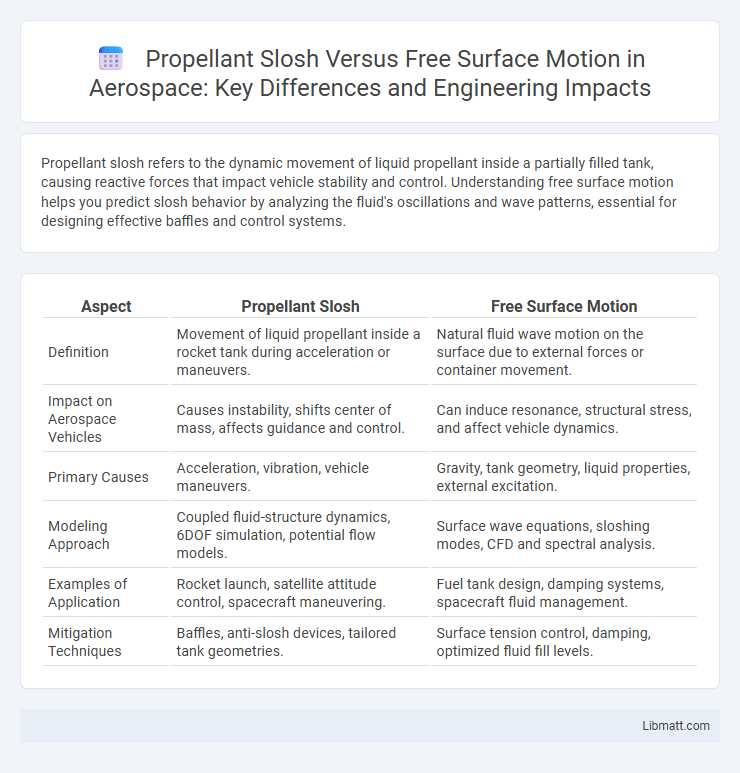

Propellant slosh refers to the dynamic movement of liquid propellant inside a partially filled tank, causing reactive forces that impact vehicle stability and control. Understanding free surface motion helps you predict slosh behavior by analyzing the fluid's oscillations and wave patterns, essential for designing effective baffles and control systems.

Table of Comparison

| Aspect | Propellant Slosh | Free Surface Motion |

|---|---|---|

| Definition | Movement of liquid propellant inside a rocket tank during acceleration or maneuvers. | Natural fluid wave motion on the surface due to external forces or container movement. |

| Impact on Aerospace Vehicles | Causes instability, shifts center of mass, affects guidance and control. | Can induce resonance, structural stress, and affect vehicle dynamics. |

| Primary Causes | Acceleration, vibration, vehicle maneuvers. | Gravity, tank geometry, liquid properties, external excitation. |

| Modeling Approach | Coupled fluid-structure dynamics, 6DOF simulation, potential flow models. | Surface wave equations, sloshing modes, CFD and spectral analysis. |

| Examples of Application | Rocket launch, satellite attitude control, spacecraft maneuvering. | Fuel tank design, damping systems, spacecraft fluid management. |

| Mitigation Techniques | Baffles, anti-slosh devices, tailored tank geometries. | Surface tension control, damping, optimized fluid fill levels. |

Introduction to Propellant Slosh and Free Surface Motion

Propellant slosh refers to the movement of liquid fuel inside a tank, influenced by the vehicle's acceleration and vibrations, which can affect stability and control. Free surface motion describes the behavior of the liquid's surface as it moves and oscillates freely within the container, impacting dynamic pressure distribution. Understanding these fluid dynamics is crucial for designing propulsion systems to ensure Your spacecraft maintains optimal performance and safety during flight.

Defining Propellant Slosh in Aerospace Systems

Propellant slosh in aerospace systems refers to the dynamic movement of liquid fuel inside a tank caused by spacecraft accelerations, rotations, or external forces. This fluid motion impacts vehicle stability, control, and structural integrity, necessitating precise modeling to predict slosh behavior. Understanding your spacecraft's propellant slosh dynamics helps optimize tank design and improve flight performance.

What is Free Surface Motion?

Free surface motion refers to the dynamic behavior of a liquid's surface within a container, characterized by waves and oscillations caused by external forces or movements. This phenomenon significantly affects the stability and control of spacecraft and vehicles, as the shifting liquid mass can alter the center of gravity and induce unwanted forces. Understanding free surface motion is crucial for accurately modeling propellant behavior and minimizing slosh effects in aerospace applications.

Key Differences: Propellant Slosh vs Free Surface Motion

Propellant slosh involves the dynamic movement of liquid propellant within a partially filled tank, significantly impacting the stability and control of aerospace vehicles through momentum transfer and fluid-structure interaction. Free surface motion refers to the natural wave-like behavior of a liquid's surface without significant external forces, primarily characterized by surface tension and gravity-induced oscillations in stationary or slow-moving containers. The key differences lie in the complexity and impact on system dynamics, where propellant slosh actively affects vehicle navigation and control systems, whereas free surface motion is a passive phenomenon governed by fluid mechanics principles.

Physical Principles Governing Slosh Dynamics

Propellant slosh dynamics are governed by the interplay of fluid inertia, gravitational forces, and container geometry, leading to oscillatory fluid motion within partially filled tanks. Free surface motion occurs as the fluid's free boundary deforms under acceleration, creating wave patterns influenced by fluid viscosity, surface tension, and tank shape. Understanding these physical principles is critical for predicting slosh-induced forces that affect the stability and control of spacecraft and launch vehicles.

Effects of Free Surface Motion on Fluid Behavior

Free surface motion significantly influences fluid behavior by creating complex wave patterns and internal fluid movements that affect stability and control within a propellant tank. Unlike propellant slosh, which involves the mass motion of the liquid as a whole, free surface motion focuses on surface deformation and oscillations that can lead to uneven pressure distributions impacting your vehicle's dynamics. Understanding these interactions is crucial for optimizing tank design to reduce disturbances during spacecraft maneuvers or launch sequences.

Impact on Vehicle Stability and Control

Propellant slosh generates dynamic forces that can disrupt vehicle stability by causing unbalanced motion within the tanks, impacting control systems and maneuver precision. Free surface motion amplifies these effects through fluid oscillations that shift the vehicle's center of mass unpredictably, leading to unstable flight dynamics. Accurate modeling and mitigation of both phenomena are critical for maintaining control authority and ensuring safe, precise vehicle operation.

Modeling and Simulation Techniques

Modeling propellant slosh involves complex fluid-structure interaction techniques, often using Computational Fluid Dynamics (CFD) coupled with rigid body dynamics to simulate the impact of liquid movement on vehicle stability. In contrast, free surface motion simulations typically utilize Volume of Fluid (VOF) or Level Set methods to capture the interface dynamics between liquid and gas phases without rigid body constraints. Your simulation accuracy improves significantly by selecting the appropriate modeling technique tailored to the specific flow conditions and container geometry.

Mitigation Strategies for Propellant Slosh and Free Surface Motion

Mitigation strategies for propellant slosh and free surface motion primarily include the use of anti-slosh baffles, which disrupt fluid movement within the tank to reduce oscillations. Incorporating diaphragms or bladder systems can isolate propellant and minimize free surface effects, enhancing vehicle stability during maneuvers. Advanced computational fluid dynamics (CFD) modeling also aids in designing tank geometries that optimize slosh damping and improve overall system performance.

Future Research Directions and Technological Advancements

Future research directions in propellant slosh focus on developing advanced computational fluid dynamics models to accurately predict free surface motion within microgravity environments, enhancing spacecraft stability. Technological advancements include the integration of smart sensors and active control systems to mitigate slosh-induced disturbances in real-time, improving mission reliability. Emerging materials for propellant tanks and innovative damping mechanisms are being explored to optimize fuel management and reduce dynamic instabilities during various flight phases.

Propellant Slosh vs Free Surface Motion Infographic

libmatt.com

libmatt.com