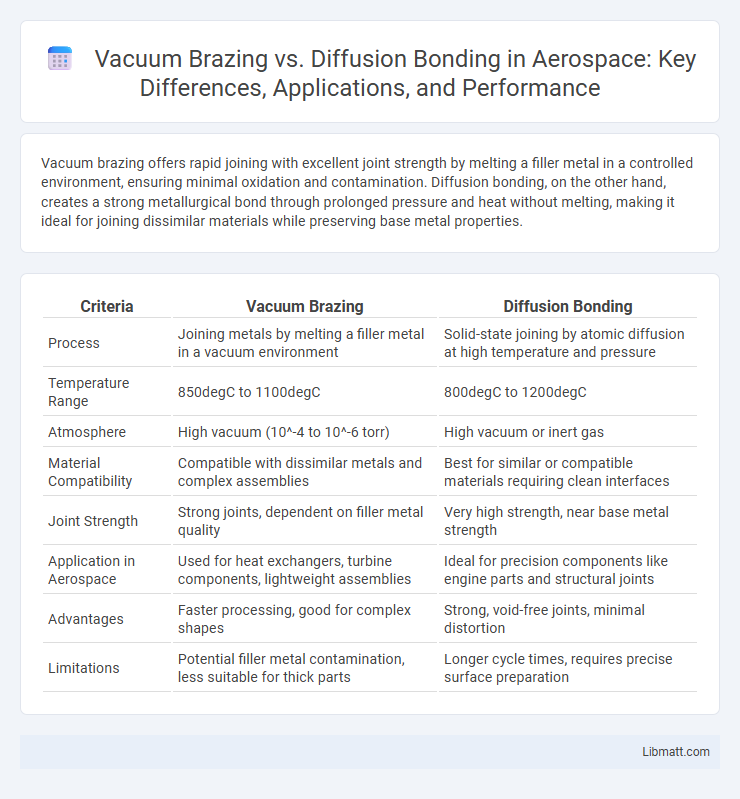

Vacuum brazing offers rapid joining with excellent joint strength by melting a filler metal in a controlled environment, ensuring minimal oxidation and contamination. Diffusion bonding, on the other hand, creates a strong metallurgical bond through prolonged pressure and heat without melting, making it ideal for joining dissimilar materials while preserving base metal properties.

Table of Comparison

| Criteria | Vacuum Brazing | Diffusion Bonding |

|---|---|---|

| Process | Joining metals by melting a filler metal in a vacuum environment | Solid-state joining by atomic diffusion at high temperature and pressure |

| Temperature Range | 850degC to 1100degC | 800degC to 1200degC |

| Atmosphere | High vacuum (10^-4 to 10^-6 torr) | High vacuum or inert gas |

| Material Compatibility | Compatible with dissimilar metals and complex assemblies | Best for similar or compatible materials requiring clean interfaces |

| Joint Strength | Strong joints, dependent on filler metal quality | Very high strength, near base metal strength |

| Application in Aerospace | Used for heat exchangers, turbine components, lightweight assemblies | Ideal for precision components like engine parts and structural joints |

| Advantages | Faster processing, good for complex shapes | Strong, void-free joints, minimal distortion |

| Limitations | Potential filler metal contamination, less suitable for thick parts | Longer cycle times, requires precise surface preparation |

Introduction to Vacuum Brazing and Diffusion Bonding

Vacuum brazing involves joining metals by melting a filler metal in a vacuum environment, ensuring strong, clean, and corrosion-resistant joints without oxidation. Diffusion bonding, a solid-state process, produces joints by applying high pressure and temperature, enabling atomic diffusion across interface surfaces for superior mechanical strength. Your choice between these methods depends on factors like materials, joint complexity, and desired strength in high-precision applications.

Fundamental Principles of Each Joining Method

Vacuum brazing utilizes a filler metal with a lower melting point than the base materials, which melts in a vacuum environment to create a strong, metallurgical bond upon cooling. Diffusion bonding relies on solid-state atomic diffusion between contacting surfaces under high temperature and pressure, allowing atoms to migrate across the interface without melting. Your choice between these methods depends on factors like temperature sensitivity, joint strength requirements, and the materials involved.

Materials Compatibility and Selection Criteria

Vacuum brazing is highly compatible with dissimilar metals and alloys, offering flexibility for joining complex assemblies with varying thermal expansion rates, making it ideal for stainless steel, copper, and nickel-based materials. Diffusion bonding requires precise matching of base metals, typically similar or compatible materials such as titanium alloys or superalloys, to prevent intermetallic formation and ensure a strong metallurgical bond. Selection criteria hinge on operating temperature, joint strength requirements, component complexity, and material microstructure sensitivity, with vacuum brazing favored for metallurgically stable joints and diffusion bonding preferred for high-performance aerospace and nuclear applications.

Process Parameters and Equipment Requirements

Vacuum brazing requires precise temperature control typically between 750degC and 1,100degC in a high-vacuum chamber below 10^-3 Pa to prevent oxidation and contamination. Diffusion bonding operates at lower temperatures, around 50-80% of the base metals' melting points, with applied pressure of 5-50 MPa in a vacuum or inert atmosphere to enable atomic diffusion. Your choice depends on available equipment, where vacuum brazing demands specialized furnaces with vacuum pumps while diffusion bonding requires presses capable of applying uniform pressure during extended heating cycles.

Joint Strength and Microstructural Characteristics

Vacuum brazing creates joints by melting a filler metal, resulting in strong bonds with distinct microstructural interfaces between the base metals and filler, which can sometimes introduce brittle intermetallic phases. Diffusion bonding produces joints through solid-state atomic diffusion under pressure and elevated temperature, leading to a seamless microstructure with superior mechanical strength and minimal grain boundary disruptions. Your choice between vacuum brazing and diffusion bonding should consider the desired joint strength and microstructural integrity for the specific application.

Applications in Aerospace, Automotive, and Electronics

Vacuum brazing is widely used in aerospace for joining complex engine components and heat exchangers due to its ability to create strong, leak-proof joints with high thermal conductivity. In the automotive industry, vacuum brazing facilitates efficient assembly of heat exchangers, battery components, and turbochargers, while diffusion bonding is preferred for manufacturing lightweight, high-strength structural parts and turbine blades. Electronics applications leverage diffusion bonding for creating hermetic seals and integrating semiconductor materials, enabling miniaturization and enhanced thermal management in microelectronics and sensors.

Cost Comparison and Production Scalability

Vacuum brazing offers lower upfront costs and faster production cycles, making it more cost-effective for high-volume manufacturing, while diffusion bonding involves higher equipment investment and longer processing times suited for specialized, low-volume applications requiring superior joint strength. Your choice depends on budget constraints and production scale, as vacuum brazing accommodates scalable batch processing, whereas diffusion bonding excels in precision and material integrity for smaller runs. Cost comparison clearly favors vacuum brazing for mass production, whereas diffusion bonding's scalability is limited but justified by enhanced joint performance in critical applications.

Advantages and Limitations of Vacuum Brazing

Vacuum brazing offers superior joint strength and corrosion resistance by creating uniform, void-free bonds through high-temperature processes in a controlled vacuum environment. It enables precise joining of dissimilar metals with minimal oxidation and contamination, which is ideal for complex assemblies in aerospace and automotive industries. Your limitations include sensitivity to joint fit-up tolerances and the requirement for expensive vacuum equipment, which may increase production costs compared to diffusion bonding.

Benefits and Challenges of Diffusion Bonding

Diffusion bonding offers significant benefits such as producing strong, high-integrity joints with minimal distortion and the ability to join dissimilar materials without filler metals. This process excels in applications requiring precision and clean joints, particularly in aerospace and electronics industries. Challenges include the need for high temperature and pressure, precise surface preparation, and long processing times which can increase production costs and complexity.

Choosing the Right Method: Key Considerations

Vacuum brazing offers rapid joining with excellent joint strength and is ideal for complex assemblies requiring minimal distortion, while diffusion bonding provides superior metallurgical bonds at the atomic level for high-temperature and high-stress applications. Material compatibility, joint design, thermal cycles, and production volume are critical factors influencing the choice, as vacuum brazing suits mass production and dissimilar metals, whereas diffusion bonding excels in aerospace and nuclear industries demanding precise control. Cost implications, equipment availability, and desired mechanical properties must also be evaluated to select the optimal bonding technique for specific manufacturing requirements.

Vacuum Brazing vs Diffusion Bonding Infographic

libmatt.com

libmatt.com