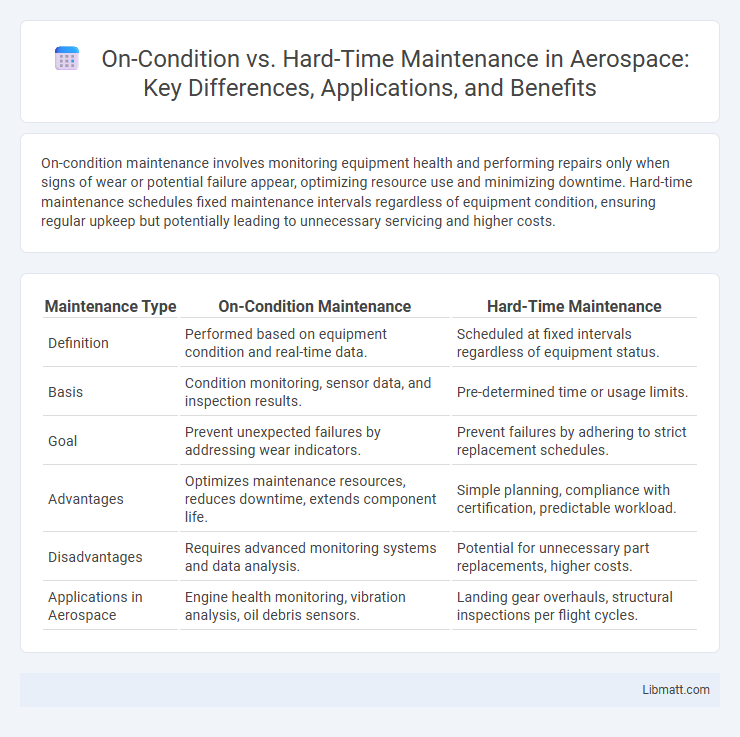

On-condition maintenance involves monitoring equipment health and performing repairs only when signs of wear or potential failure appear, optimizing resource use and minimizing downtime. Hard-time maintenance schedules fixed maintenance intervals regardless of equipment condition, ensuring regular upkeep but potentially leading to unnecessary servicing and higher costs.

Table of Comparison

| Maintenance Type | On-Condition Maintenance | Hard-Time Maintenance |

|---|---|---|

| Definition | Performed based on equipment condition and real-time data. | Scheduled at fixed intervals regardless of equipment status. |

| Basis | Condition monitoring, sensor data, and inspection results. | Pre-determined time or usage limits. |

| Goal | Prevent unexpected failures by addressing wear indicators. | Prevent failures by adhering to strict replacement schedules. |

| Advantages | Optimizes maintenance resources, reduces downtime, extends component life. | Simple planning, compliance with certification, predictable workload. |

| Disadvantages | Requires advanced monitoring systems and data analysis. | Potential for unnecessary part replacements, higher costs. |

| Applications in Aerospace | Engine health monitoring, vibration analysis, oil debris sensors. | Landing gear overhauls, structural inspections per flight cycles. |

Introduction to Aircraft Maintenance Strategies

On-condition maintenance relies on real-time monitoring and inspection data to determine when aircraft components require servicing, optimizing resource use and reducing unnecessary part replacements. Hard-time maintenance schedules fixed intervals for inspections and part replacements regardless of actual component condition, prioritizing safety through preventive measures. Your choice between these strategies impacts operational efficiency, maintenance costs, and aircraft reliability.

Understanding On-Condition Maintenance

On-condition maintenance involves continuous monitoring of equipment health through sensors and diagnostic tools to detect wear or potential failure before it occurs, enabling targeted repairs precisely when needed. This approach contrasts with hard-time maintenance, which relies on predetermined intervals regardless of actual machine condition, potentially leading to unnecessary maintenance or unexpected failures. By adopting on-condition maintenance, you optimize asset lifespan and reduce downtime by basing service decisions on real data and actual equipment status.

Defining Hard-Time Maintenance

Hard-time maintenance refers to a preventive maintenance strategy where equipment or components are replaced or serviced at fixed, predetermined intervals regardless of their actual condition or performance. This approach minimizes unexpected failures by adhering to strict time-based schedules, often dictated by manufacturer recommendations or regulatory requirements. Unlike on-condition maintenance, hard-time maintenance does not rely on real-time condition monitoring or diagnostic data to determine the optimal service time.

Key Differences Between On-Condition and Hard-Time Maintenance

On-condition maintenance relies on continuous monitoring and diagnostic data to perform repairs only when equipment shows signs of wear or failure, enhancing efficiency and reducing unnecessary downtime. Hard-time maintenance schedules repairs at fixed intervals regardless of equipment condition, prioritizing predictability but potentially leading to premature part replacements. Your decision between these methods should consider factors like equipment criticality, cost implications, and the availability of real-time condition monitoring technologies.

Advantages of On-Condition Maintenance

On-condition maintenance offers the advantage of monitoring equipment health in real time, allowing you to perform repairs only when needed, which reduces unnecessary downtime and maintenance costs. It enhances asset reliability by preventing unexpected failures through timely interventions based on actual equipment conditions. This approach maximizes equipment lifespan and optimizes resource allocation, making maintenance more efficient and cost-effective.

Benefits of Hard-Time Maintenance

Hard-time maintenance offers predictable scheduling by performing maintenance tasks at fixed intervals based on manufacturer recommendations or historical data, reducing unexpected equipment failures. It simplifies resource planning and budgeting since maintenance activities and downtime are planned in advance, ensuring consistent operational efficiency. Your facility can maintain compliance with safety and regulatory standards through systematic, time-based inspections and servicing.

Operational Considerations for Maintenance Selection

On-condition maintenance relies on continuous monitoring of equipment health through sensors and diagnostic tools, allowing timely interventions based on actual wear or performance thresholds, which can optimize resource use and reduce downtime. Hard-time maintenance schedules maintenance activities based on fixed intervals regardless of equipment condition, ensuring predictable resource allocation but potentially resulting in unnecessary part replacements or unexpected failures. Your decision between these strategies should consider operational factors such as equipment criticality, failure modes, measurement capabilities, and cost-efficiency to balance reliability and maintenance expenses.

Impact on Safety and Reliability

On-condition maintenance enhances safety and reliability by utilizing real-time monitoring and predictive analytics to address equipment issues before failure occurs, reducing the risk of unexpected breakdowns. Hard-time maintenance relies on fixed schedules regardless of current equipment condition, which may lead to either premature part replacement or unexpected failures, affecting overall system reliability and safety. Your choice between these strategies directly influences operational risk management and asset performance optimization.

Cost Implications of Maintenance Approaches

On-condition maintenance reduces overall costs by targeting repairs only when diagnostic indicators signal potential failure, preventing unnecessary part replacements and labor. Hard-time maintenance often incurs higher expenses due to routine replacements regardless of equipment condition, leading to premature part disposal and increased downtime. Your operational budget benefits from on-condition strategies through optimized resource allocation and minimized unplanned outages.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy involves evaluating equipment condition and failure risk. On-condition maintenance uses real-time data and condition monitoring tools to perform repairs only when signs of wear or potential failure appear, reducing unnecessary downtime and costs. Hard-time maintenance follows a fixed schedule based on average life expectancy, ensuring preventive action before failure but potentially increasing maintenance frequency and expenses.

On-condition vs Hard-time maintenance Infographic

libmatt.com

libmatt.com