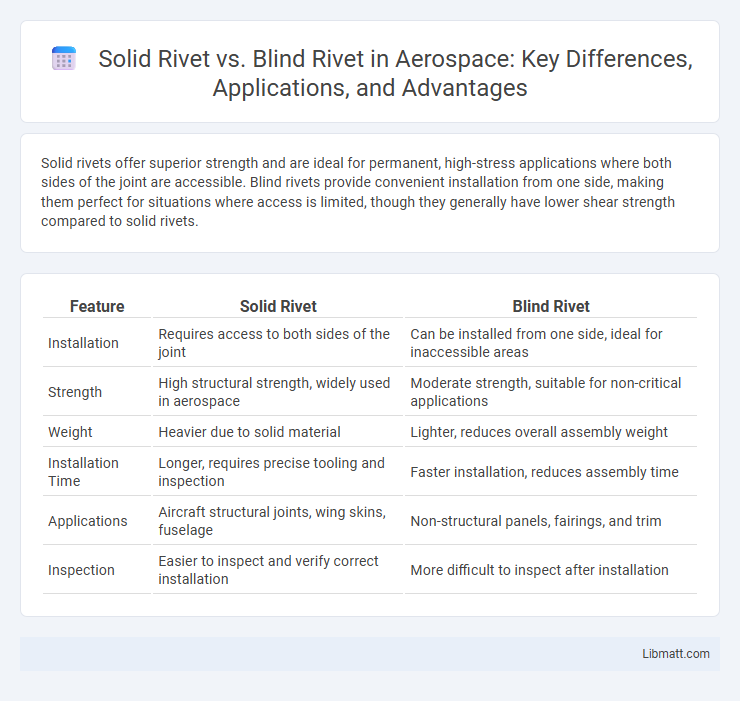

Solid rivets offer superior strength and are ideal for permanent, high-stress applications where both sides of the joint are accessible. Blind rivets provide convenient installation from one side, making them perfect for situations where access is limited, though they generally have lower shear strength compared to solid rivets.

Table of Comparison

| Feature | Solid Rivet | Blind Rivet |

|---|---|---|

| Installation | Requires access to both sides of the joint | Can be installed from one side, ideal for inaccessible areas |

| Strength | High structural strength, widely used in aerospace | Moderate strength, suitable for non-critical applications |

| Weight | Heavier due to solid material | Lighter, reduces overall assembly weight |

| Installation Time | Longer, requires precise tooling and inspection | Faster installation, reduces assembly time |

| Applications | Aircraft structural joints, wing skins, fuselage | Non-structural panels, fairings, and trim |

| Inspection | Easier to inspect and verify correct installation | More difficult to inspect after installation |

Introduction to Rivets: Solid vs Blind

Solid rivets consist of a solid cylindrical shaft and require access to both sides of the materials being joined for installation, providing high strength and durability ideal for structural applications. Blind rivets, also known as pop rivets, can be installed from one side, making them suitable for inaccessible or hollow sections, though they generally offer lower shear strength compared to solid rivets. Both rivet types serve critical roles in manufacturing and construction, with solid rivets favored in aerospace and heavy machinery, while blind rivets excel in automotive and sheet metal assembly.

What is a Solid Rivet?

A solid rivet is a mechanical fastener made from a single piece of metal, commonly aluminum, steel, or copper, which is installed by deforming the rivet tail to create a strong, permanent joint. Unlike blind rivets, solid rivets require access to both sides of the assembly for installation, making them ideal for applications in aerospace, automotive, and construction industries where high strength and reliability are critical. The robust nature of solid rivets offers superior shear and tensile strength compared to blind rivets, ensuring durable fastening in high-stress environments.

What is a Blind Rivet?

A blind rivet, also known as a pop rivet, is a fastener designed to join materials where access is only available from one side. It consists of a tubular rivet body and a mandrel that pulls through the body to deform the rivet, creating a strong, permanent joint. Blind rivets are widely used in applications such as automotive, aerospace, and construction due to their ease of installation and reliability in fastening thin materials.

Installation Process: Solid Rivet vs Blind Rivet

Solid rivets require access to both sides of the assembly for installation, involving heating, placing, and hammering the rivet to form a secure joint. Blind rivets, also known as pop rivets, can be installed from one side using a rivet gun, making them ideal for applications with limited access. The installation process of blind rivets is faster and requires less specialized equipment compared to solid rivets, which demand more manual effort and precision.

Strength and Durability Comparison

Solid rivets provide superior strength and durability due to their one-piece construction, making them ideal for high-stress applications in aerospace and structural industries. Blind rivets, while easier to install and suitable for limited access situations, generally offer lower shear and tensile strength compared to solid rivets. When your project requires maximum load-bearing capacity and long-term reliability, solid rivets are typically the preferred choice.

Application Areas for Each Rivet Type

Solid rivets are primarily used in heavy-duty applications such as aerospace, shipbuilding, and structural steel where high strength and vibration resistance are critical. Blind rivets are favored in automotive, electronics, and construction industries for fastening materials where access is only available from one side. These rivet types optimize assembly processes according to their specific mechanical properties and installation requirements.

Advantages of Solid Rivets

Solid rivets offer exceptional strength and durability due to their one-piece design, making them ideal for high-stress applications in aerospace and structural engineering. Their ability to create a permanent, vibration-resistant joint ensures long-lasting stability in critical assemblies. You benefit from solid rivets' superior shear and tensile strength compared to blind rivets, especially where access to both sides of the material is possible.

Advantages of Blind Rivets

Blind rivets provide a significant advantage by allowing installation from one side of the workpiece, making them ideal for applications where access to the back side is limited or impossible. They offer consistent and reliable fastening, reducing assembly time and labor costs while maintaining strong joints in sheet metal, plastic, and composite materials. Your projects benefit from the versatility and ease of use of blind rivets, especially in automotive, aerospace, and construction industries.

Cost Considerations: Solid vs Blind Rivets

Solid rivets generally offer lower material costs and high durability, making them cost-effective for applications with accessible joint faces and high strength requirements. Blind rivets, while typically more expensive per unit, reduce labor costs by enabling easier installation in hard-to-reach or single-sided joints, saving time and minimizing assembly complexity. Your choice between solid and blind rivets should balance the initial rivet price against installation efficiency and long-term performance needs.

Choosing the Right Rivet for Your Project

Choosing the right rivet for your project depends on accessibility and strength requirements, with solid rivets offering superior shear strength and durability, ideal for heavy-duty applications where both sides of the material are accessible. Blind rivets, also known as pop rivets, provide a practical solution for fastening when only one side of the assembly is reachable, making them perfect for quick installations and maintenance in tight spaces. Understanding your project's mechanical demands and installation constraints ensures you select between the robust performance of solid rivets and the convenient versatility of blind rivets.

Solid rivet vs Blind rivet Infographic

libmatt.com

libmatt.com