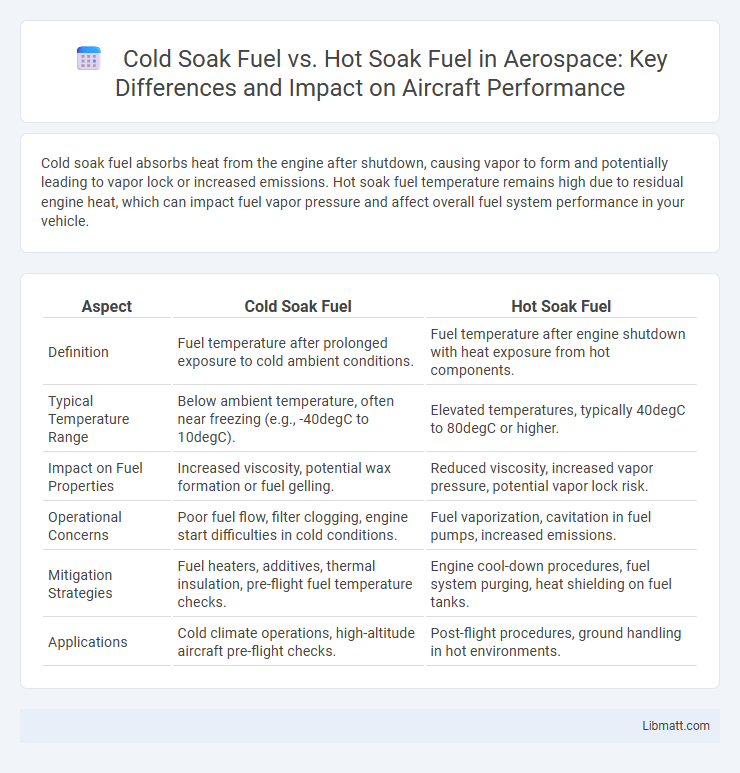

Cold soak fuel absorbs heat from the engine after shutdown, causing vapor to form and potentially leading to vapor lock or increased emissions. Hot soak fuel temperature remains high due to residual engine heat, which can impact fuel vapor pressure and affect overall fuel system performance in your vehicle.

Table of Comparison

| Aspect | Cold Soak Fuel | Hot Soak Fuel |

|---|---|---|

| Definition | Fuel temperature after prolonged exposure to cold ambient conditions. | Fuel temperature after engine shutdown with heat exposure from hot components. |

| Typical Temperature Range | Below ambient temperature, often near freezing (e.g., -40degC to 10degC). | Elevated temperatures, typically 40degC to 80degC or higher. |

| Impact on Fuel Properties | Increased viscosity, potential wax formation or fuel gelling. | Reduced viscosity, increased vapor pressure, potential vapor lock risk. |

| Operational Concerns | Poor fuel flow, filter clogging, engine start difficulties in cold conditions. | Fuel vaporization, cavitation in fuel pumps, increased emissions. |

| Mitigation Strategies | Fuel heaters, additives, thermal insulation, pre-flight fuel temperature checks. | Engine cool-down procedures, fuel system purging, heat shielding on fuel tanks. |

| Applications | Cold climate operations, high-altitude aircraft pre-flight checks. | Post-flight procedures, ground handling in hot environments. |

Introduction to Cold Soak Fuel and Hot Soak Fuel

Cold soak fuel refers to the gasoline or diesel fuel that remains in an engine's fuel system after it has cooled down following operation, often leading to vapor formation and potential performance issues. Hot soak fuel, on the other hand, pertains to the fuel present in the engine after it has been shut down but remains hot due to residual engine heat, causing increased vapor pressure and emissions. Understanding the differences between cold soak and hot soak fuel is crucial for optimizing fuel system design and emission control strategies in modern vehicles.

Understanding Fuel Soak Processes

Cold soak fuel refers to the fuel condition after the vehicle has been parked and the engine cooled down, typically causing fuel temperature to drop and potentially leading to vapor lock or difficulty in starting. Hot soak fuel occurs when the engine is turned off but remains hot, causing fuel temperatures in the fuel lines and tank to rise, which can increase vapor pressure and evaporative emissions. Understanding these processes is critical for optimizing fuel system design, improving engine start performance, and meeting emissions regulations.

Key Differences Between Cold Soak and Hot Soak Fuels

Cold soak fuel remains at ambient temperatures after engine shutdown, leading to potential vapor lock and fuel system issues due to condensation and lower volatility. Hot soak fuel, by contrast, stays heated by the engine's residual heat, increasing evaporation rates that can cause higher emissions and potential fuel degradation. Your vehicle's performance and emission controls depend on managing these differences to optimize fuel stability and engine reliability.

Fuel Performance in Cold Soak Conditions

Cold soak fuel performance is influenced by the thickening and potential wax crystallization that occurs at low temperatures, leading to reduced fuel flow and engine starting difficulties. Hot soak fuel, by contrast, remains in a heated state after engine shutdown, which can cause vapor lock and increased fuel volatility but generally maintains better flow characteristics. Optimizing fuel formulations to prevent cold filter plugging and ensure consistent vapor pressure enhances reliable engine operation in cold soak conditions.

Fuel Behavior in Hot Soak Scenarios

Fuel behavior in hot soak scenarios involves significant temperature-induced changes, causing vapor pressure to increase and promoting fuel vaporization within the tank and fuel lines. This process can lead to vapor lock, reduced fuel pump efficiency, and increased evaporative emissions, impacting engine performance and emissions control systems. Understanding the distinction between cold soak and hot soak fuel characteristics is essential for optimizing fuel formulations and vehicle evaporative emission technologies.

Impact on Engine Efficiency and Reliability

Cold soak fuel can cause incomplete vaporization, leading to poor combustion and reduced engine efficiency due to lower fuel-air mixture quality. Hot soak fuel promotes better evaporation, enhancing combustion stability and maintaining consistent engine performance. Understanding these impacts helps you optimize fuel management for improved engine reliability and efficiency.

Emissions and Environmental Considerations

Cold soak fuel results in lower evaporative emissions compared to hot soak fuel, as the fuel system remains relatively cooler and releases fewer volatile organic compounds (VOCs). Hot soak fuel, heated by engine operation, generates higher VOC emissions that contribute significantly to urban air pollution and smog formation. Managing Your vehicle's fuel temperature through advanced evaporative control systems reduces environmental impact by minimizing harmful emissions during hot soak conditions.

Testing and Measurement Methods

Cold soak fuel testing involves measuring fuel volatility and evaporative emissions after the fuel tank and lines have cooled to ambient temperature, utilizing techniques like the cold soak canister test and vapor recovery analysis. Hot soak fuel testing occurs immediately after engine shutdown when residual heat causes fuel temperatures to remain elevated, assessed through hot soak emission tests that monitor permeation and canister purge efficiency. Your choice of testing method depends on the specific evaluation of evaporative losses and emission control system performance under varying temperature conditions.

Industry Applications and Relevant Standards

Cold soak fuel testing is critical in automotive emissions assessment to evaluate evaporative emissions when the engine is off and fuel temperature is low, primarily governed by standards like SAE J2715 and EPA's RVP testing protocols. Hot soak fuel testing measures emissions after engine shutdown when fuel and components are hot, widely applied in vehicle certification and durability studies under standards such as SAE J1624 and CARB's enhanced evaporative emission procedures. Both testing methods support regulatory compliance for fuel systems and vapor recovery, crucial in reducing volatile organic compounds (VOCs) and meeting stringent global environmental regulations.

Best Practices for Managing Fuel Soak Effects

Managing fuel soak effects requires minimizing exposure of fuel systems to high temperatures, especially in hot soak conditions where fuel overheats and vaporizes, causing vapor lock and reduced engine performance. Best practices include insulating fuel lines, using heat shields, and parking vehicles in shaded or ventilated areas to reduce heat absorption. Regularly inspecting fuel system components for leaks and maintaining optimal fuel pressure also mitigate adverse effects associated with fuel soak.

cold soak fuel vs hot soak fuel Infographic

libmatt.com

libmatt.com