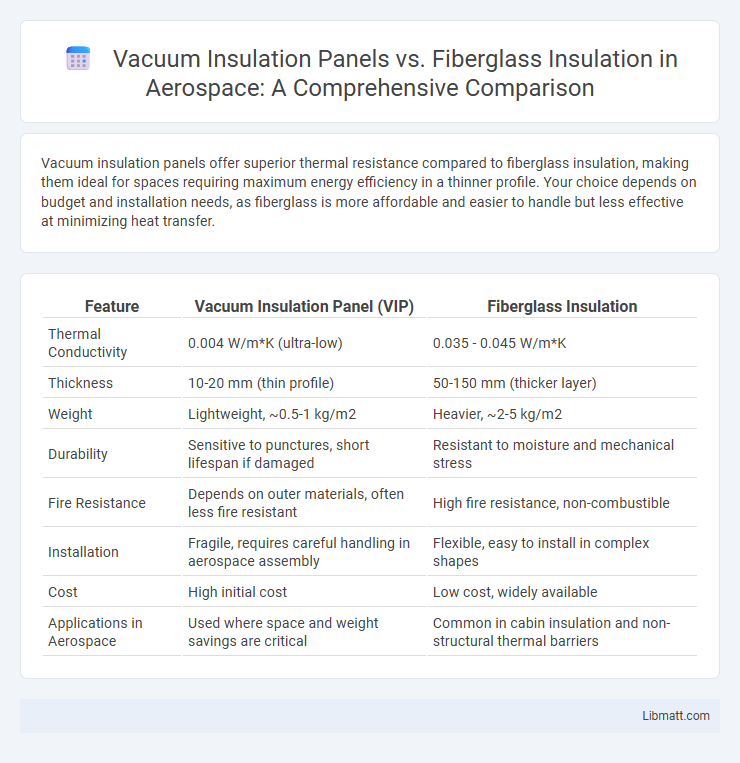

Vacuum insulation panels offer superior thermal resistance compared to fiberglass insulation, making them ideal for spaces requiring maximum energy efficiency in a thinner profile. Your choice depends on budget and installation needs, as fiberglass is more affordable and easier to handle but less effective at minimizing heat transfer.

Table of Comparison

| Feature | Vacuum Insulation Panel (VIP) | Fiberglass Insulation |

|---|---|---|

| Thermal Conductivity | 0.004 W/m*K (ultra-low) | 0.035 - 0.045 W/m*K |

| Thickness | 10-20 mm (thin profile) | 50-150 mm (thicker layer) |

| Weight | Lightweight, ~0.5-1 kg/m2 | Heavier, ~2-5 kg/m2 |

| Durability | Sensitive to punctures, short lifespan if damaged | Resistant to moisture and mechanical stress |

| Fire Resistance | Depends on outer materials, often less fire resistant | High fire resistance, non-combustible |

| Installation | Fragile, requires careful handling in aerospace assembly | Flexible, easy to install in complex shapes |

| Cost | High initial cost | Low cost, widely available |

| Applications in Aerospace | Used where space and weight savings are critical | Common in cabin insulation and non-structural thermal barriers |

Introduction to Insulation Materials

Vacuum Insulation Panels (VIPs) offer superior thermal resistance by minimizing heat transfer through a core material encased in a gas-tight envelope, achieving R-values significantly higher than traditional insulation. Fiberglass insulation, composed of fine glass fibers, provides effective thermal and acoustic insulation by trapping air pockets but requires greater thickness for comparable performance. Your choice between VIPs and fiberglass insulation depends on factors like space constraints, thermal efficiency needs, and budget considerations.

What Are Vacuum Insulation Panels?

Vacuum Insulation Panels (VIPs) are advanced thermal insulation materials consisting of a rigid core encased in a gas-tight envelope, creating a vacuum that significantly reduces heat transfer. Compared to traditional fiberglass insulation, VIPs offer superior thermal performance with much thinner profiles, making them ideal for applications where space-saving and high efficiency are crucial. Your choice of insulation can greatly impact energy savings and comfort, especially when opting for materials like VIPs that provide a high R-value in minimal thickness.

Understanding Fiberglass Insulation

Fiberglass insulation consists of fine glass fibers woven into a mat, providing thermal resistance by trapping air within its structure. This material is widely used due to its affordability, ease of installation, and effective performance in reducing heat transfer. Understanding fiberglass insulation helps you evaluate its suitability for energy-efficient applications compared to advanced alternatives like vacuum insulation panels.

Thermal Performance Comparison

Vacuum Insulation Panels (VIPs) provide superior thermal performance with R-values ranging from 50 to 60 per inch, significantly higher than fiberglass insulation, which typically offers R-values between 2.2 and 4 per inch. This means VIPs deliver enhanced energy efficiency and space savings in applications where insulation thickness is limited. Your choice of VIP over fiberglass insulation can result in better temperature regulation and reduced heating or cooling costs.

Space and Thickness Requirements

Vacuum insulation panels (VIPs) offer superior thermal resistance with significantly reduced thickness compared to traditional fiberglass insulation, making them ideal for applications where space is limited. Fiberglass insulation typically requires a thicker layer to achieve comparable R-values, which can impact your design flexibility and usable interior space. Choosing VIPs can maximize energy efficiency while minimizing the bulk, crucial for compact or high-performance building envelopes.

Durability and Lifespan

Vacuum insulation panels (VIPs) offer superior durability with a typical lifespan of 25 to 30 years, maintaining high thermal resistance due to their airtight construction and rigid core materials. Fiberglass insulation generally lasts around 15 to 20 years but can degrade more quickly when exposed to moisture, compression, or pest infestation, reducing its effectiveness over time. VIPs resist settling and moisture damage better, making them a longer-lasting choice in environments where insulation performance longevity is critical.

Installation Process and Complexity

Vacuum Insulation Panels (VIPs) require precise handling and careful sealing during installation to maintain their vacuum and insulating properties, demanding specialized skills and tools. Fiberglass insulation offers a more straightforward installation process, involving cutting and fitting batts or rolls into cavities with minimal specialized equipment. The complexity of installing VIPs often leads to higher labor costs and longer installation times compared to the user-friendly nature of fiberglass insulation.

Cost Analysis: Initial and Long-Term

Vacuum insulation panels (VIPs) have a higher initial cost compared to fiberglass insulation but offer superior thermal performance, which can result in significant long-term energy savings and reduced utility bills. Fiberglass insulation provides an affordable upfront investment but may require thicker application and more frequent replacement, potentially increasing maintenance costs over time. Evaluating the total cost of ownership, VIPs often yield better economic value in energy-intensive or space-restricted applications despite their premium price.

Environmental Impact and Sustainability

Vacuum insulation panels (VIPs) offer superior thermal performance and reduce energy consumption, but their production involves energy-intensive manufacturing and limited recyclability, impacting environmental sustainability. Fiberglass insulation, while less efficient in insulation value, uses abundant raw materials and is more easily recycled, contributing to a lower ecological footprint over its lifecycle. Choosing the right material balances your need for energy efficiency with long-term environmental impact and sustainability goals.

Choosing the Right Insulation for Your Needs

Vacuum insulation panels (VIPs) offer superior thermal resistance with R-values up to 50 per inch, making them ideal for applications requiring maximum space efficiency and high insulation performance. Fiberglass insulation, with R-values generally between 2.2 to 3.8 per inch, provides a cost-effective and widely available option suitable for standard residential and commercial projects. Assessing the specific thermal performance requirements, budget constraints, and installation space helps determine whether the high-efficiency but premium-priced VIPs or the versatile and affordable fiberglass insulation best meets your needs.

Vacuum Insulation Panel vs Fiberglass Insulation Infographic

libmatt.com

libmatt.com