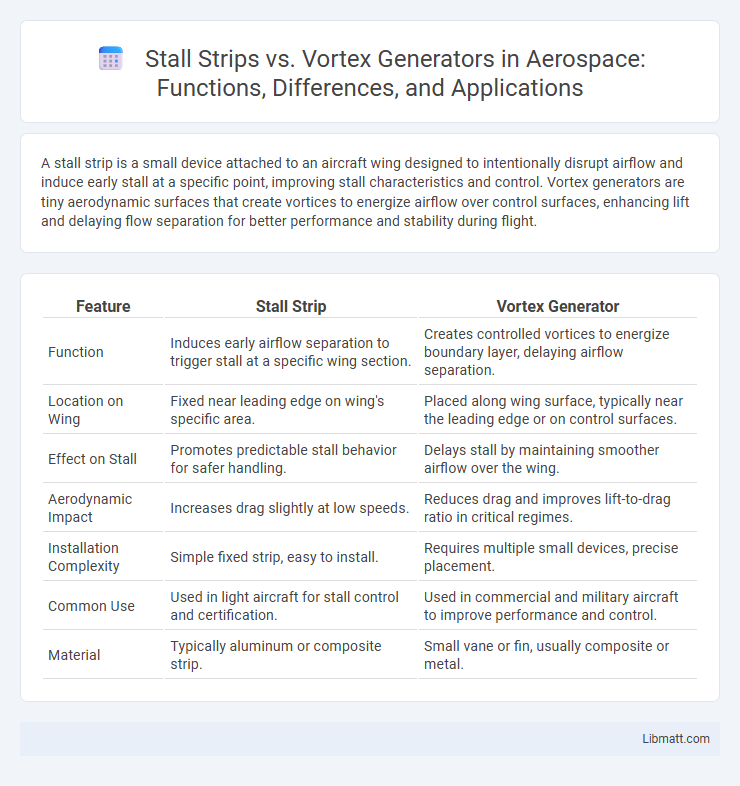

A stall strip is a small device attached to an aircraft wing designed to intentionally disrupt airflow and induce early stall at a specific point, improving stall characteristics and control. Vortex generators are tiny aerodynamic surfaces that create vortices to energize airflow over control surfaces, enhancing lift and delaying flow separation for better performance and stability during flight.

Table of Comparison

| Feature | Stall Strip | Vortex Generator |

|---|---|---|

| Function | Induces early airflow separation to trigger stall at a specific wing section. | Creates controlled vortices to energize boundary layer, delaying airflow separation. |

| Location on Wing | Fixed near leading edge on wing's specific area. | Placed along wing surface, typically near the leading edge or on control surfaces. |

| Effect on Stall | Promotes predictable stall behavior for safer handling. | Delays stall by maintaining smoother airflow over the wing. |

| Aerodynamic Impact | Increases drag slightly at low speeds. | Reduces drag and improves lift-to-drag ratio in critical regimes. |

| Installation Complexity | Simple fixed strip, easy to install. | Requires multiple small devices, precise placement. |

| Common Use | Used in light aircraft for stall control and certification. | Used in commercial and military aircraft to improve performance and control. |

| Material | Typically aluminum or composite strip. | Small vane or fin, usually composite or metal. |

Introduction to Stall Strips vs Vortex Generators

Stall strips are small, triangular aerodynamic devices installed on aircraft wings to deliberately trigger airflow separation at specific locations, improving stall behavior and control predictability. Vortex generators are small, fin-like structures designed to create controlled vortices, delaying flow separation and enhancing lift by energizing the boundary layer. Both devices optimize wing performance but serve distinct functions: stall strips manage stall onset, while vortex generators enhance overall lift and control effectiveness.

Understanding Aerodynamic Flow Disruption

Stall strips and vortex generators both manipulate airflow to enhance aerodynamic performance by delaying flow separation on aircraft wings. Stall strips create a controlled turbulent wake initiating early boundary layer separation to improve stall characteristics, while vortex generators produce streamwise vortices that energize the boundary layer and maintain attached flow. Understanding these distinct flow disruption methods is crucial for optimizing lift, reducing drag, and improving overall aerodynamic efficiency.

What are Stall Strips?

Stall strips are small, aerodynamic devices attached to aircraft wings that intentionally disrupt airflow to delay or control wing stall characteristics. They create a controlled turbulence that improves handling at high angles of attack by forcing the wing to stall more predictably. Understanding how stall strips influence your aircraft's performance is crucial for optimizing stability and safety during critical flight conditions.

How Do Vortex Generators Work?

Vortex generators work by creating small, controlled vortices that energize the airflow over surfaces like wings or turbine blades, delaying flow separation and reducing drag. These devices improve aerodynamic efficiency by maintaining smooth airflow, enhancing lift, and preventing stall at higher angles of attack. Unlike stall strips that trigger early flow separation, vortex generators stabilize airflow to optimize performance and control.

Key Differences Between Stall Strips and Vortex Generators

Stall strips and vortex generators serve different aerodynamic functions on aircraft wings; stall strips are small, angled surfaces designed to induce a controlled stall at a specific location, improving stall characteristics and handling, while vortex generators are tiny, fin-like devices that create vortices to energize boundary layer airflow, delaying flow separation and reducing drag. Stall strips primarily influence stall behavior by triggering airflow separation, whereas vortex generators enhance lift and control by maintaining airflow attachment over control surfaces at various speeds. Your choice between these devices depends on the desired aerodynamic outcome, such as improving stall predictability or optimizing lift and control efficiency.

Advantages and Disadvantages of Stall Strips

Stall strips improve airflow control on aircraft wings by inducing early stall on specific sections, enhancing low-speed handling and preventing abrupt wingdrop during stalls. Their advantages include simplicity, low weight, and ease of installation, making them a cost-effective solution for stall characteristics modification. However, stall strips can increase drag and may reduce overall aerodynamic efficiency, potentially limiting cruise performance and fuel economy.

Benefits and Limitations of Vortex Generators

Vortex generators improve airflow by creating controlled vortices, reducing drag and enhancing lift, which benefits aircraft performance and fuel efficiency. Their primary limitation lies in added surface complexity and minor weight increases, which may require regular maintenance. You should consider vortex generators when seeking aerodynamic improvements without significant structural modifications.

Application Scenarios: When to Use Stall Strips or Vortex Generators

Stall strips are primarily used in light aircraft wing designs to improve stall behavior by initiating a controlled stall at specific sections, especially during low-speed operations. Vortex generators are suitable for maintaining airflow attachment on wings, rotor blades, or surfaces experiencing boundary layer separation, enhancing performance during high-speed or high-lift conditions. Selecting between stall strips and vortex generators depends on the aircraft's aerodynamic requirements, with stall strips optimizing stall progression and vortex generators enhancing lift and delaying flow separation.

Impact on Aircraft Performance and Safety

Stall strips and vortex generators both enhance aircraft performance by improving airflow control, but their effects differ significantly. Stall strips delay flow separation over the wing, increasing stall angle and improving safety by providing predictable stall characteristics, whereas vortex generators energize boundary layer airflow to reduce drag and maintain lift at higher angles of attack, enhancing overall aerodynamic efficiency. Implementing the appropriate device depends on aircraft design and mission requirements, balancing improved handling qualities with potential trade-offs in drag and fuel efficiency.

Choosing the Right Solution for Your Aircraft

When choosing the right solution for your aircraft, understanding the differences between stall strips and vortex generators is essential. Stall strips are designed to induce controlled airflow separation at specific wing sections, enhancing stall behavior for safer handling, while vortex generators improve overall aerodynamic performance by creating vortices that energize the boundary layer and delay flow separation. Selecting the appropriate device depends on your aircraft's specific aerodynamic challenges and performance goals to optimize safety and efficiency.

Stall strip vs Vortex generator Infographic

libmatt.com

libmatt.com