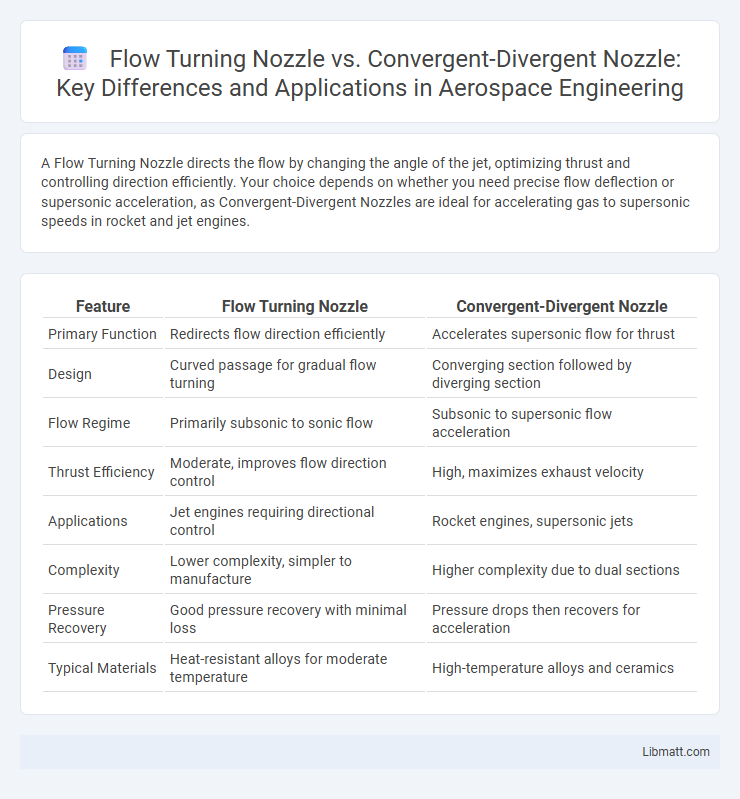

A Flow Turning Nozzle directs the flow by changing the angle of the jet, optimizing thrust and controlling direction efficiently. Your choice depends on whether you need precise flow deflection or supersonic acceleration, as Convergent-Divergent Nozzles are ideal for accelerating gas to supersonic speeds in rocket and jet engines.

Table of Comparison

| Feature | Flow Turning Nozzle | Convergent-Divergent Nozzle |

|---|---|---|

| Primary Function | Redirects flow direction efficiently | Accelerates supersonic flow for thrust |

| Design | Curved passage for gradual flow turning | Converging section followed by diverging section |

| Flow Regime | Primarily subsonic to sonic flow | Subsonic to supersonic flow acceleration |

| Thrust Efficiency | Moderate, improves flow direction control | High, maximizes exhaust velocity |

| Applications | Jet engines requiring directional control | Rocket engines, supersonic jets |

| Complexity | Lower complexity, simpler to manufacture | Higher complexity due to dual sections |

| Pressure Recovery | Good pressure recovery with minimal loss | Pressure drops then recovers for acceleration |

| Typical Materials | Heat-resistant alloys for moderate temperature | High-temperature alloys and ceramics |

Introduction to Flow Turning and Convergent-Divergent Nozzles

Flow turning nozzles are designed to redirect the flow direction efficiently, commonly used in applications requiring precise maneuvering of fluid streams, while convergent-divergent nozzles accelerate gases to supersonic speeds by first converging and then diverging the flow path. The convergent section compresses the fluid, increasing velocity until reaching the throat, where the flow becomes sonic, and the divergent section further expands and accelerates it beyond Mach 1. Understanding these nozzle types is crucial for optimizing your system's performance in aerospace, propulsion, and industrial fluid dynamics.

Fundamental Principles of Nozzle Design

Flow turning nozzles rely on gradual curvature to redirect flow direction while maintaining subsonic or supersonic velocities, optimizing pressure recovery and minimizing shock losses. Convergent-divergent nozzles utilize a critical throat area to accelerate flow to sonic speeds at the throat, then expand supersonically in the divergent section, achieving high exit velocities essential for rocket propulsion. Both designs balance pressure, velocity, and flow angle through tailored geometry to maximize thrust and efficiency based on specific aerospace applications.

Mechanisms of Flow Acceleration and Redirection

Flow Turning Nozzles accelerate and redirect fluid by altering the flow direction through curved surfaces, converting pressure energy into kinetic energy via controlled turning angles that minimize shock losses. Convergent-Divergent Nozzles increase flow velocity by first converging to sonic speed at the throat, then expanding supersonically in the divergent section, generating acceleration through area change rather than flow redirection. Understanding these mechanisms helps optimize Your design choice for efficient thrust generation or flow control in aerospace and propulsion systems.

Flow Turning Nozzle: Structure and Functionality

A Flow Turning Nozzle features curved walls that gradually change the flow direction, optimizing aerodynamic efficiency by minimizing shock losses and flow separation. Its structure allows smooth deflection of high-speed gases, enhancing thrust vector control and improving propulsion system performance. Designed for supersonic and hypersonic applications, the nozzle's precise geometry manages expansion waves and flow turning angles to maximize exhaust velocity and overall engine efficiency.

Convergent-Divergent Nozzle: Structure and Functionality

The convergent-divergent nozzle features a tapered design with a narrowing convergent section followed by an expanding divergent section, enabling supersonic flow acceleration. Its functionality relies on the transition from subsonic to supersonic speeds at the throat, optimizing thrust generation in aerospace propulsion systems. This nozzle type is essential in rocket engines and supersonic jet applications due to its ability to efficiently manage high-velocity exhaust gases.

Comparative Analysis: Performance and Efficiency

Flow turning nozzles excel in applications requiring smooth directional changes with minimal flow separation, enhancing overall aerodynamic efficiency in compact systems. Convergent-divergent nozzles, designed for supersonic flow acceleration, offer superior thrust generation and optimal performance at high Mach numbers by effectively managing shock waves and expansion fans. Your choice between the two depends on the desired flow characteristics and efficiency priorities, with flow turning nozzles favoring controlled flow direction and convergent-divergent nozzles maximizing high-speed propulsion efficiency.

Applications in Aerospace and Propulsion Systems

Flow turning nozzles optimize thrust vector control and efficiency in aerospace applications by redirecting exhaust flow without significant pressure loss, enhancing maneuverability in jet engines and VTOL systems. Convergent-divergent nozzles excel in supersonic propulsion, enabling exhaust acceleration beyond Mach 1 for rockets and high-speed aircraft, critical in launch vehicles and supersonic cruise missiles. Both nozzle types are integral in propulsion systems, with flow turning nozzles favored for precise directional thrust and convergent-divergent designs dominating high-speed, high-altitude flight regimes.

Advantages and Disadvantages of Each Nozzle Type

Flow turning nozzles provide efficient direction control of exhaust gases with minimal flow separation, enhancing thrust vectoring capabilities in propulsion systems. Convergent-divergent nozzles excel in supersonic flow acceleration by achieving optimal expansion and higher exit velocities, but can suffer from flow instability and complex shock wave formations under off-design conditions. While flow turning nozzles offer better maneuverability and structural simplicity, convergent-divergent nozzles deliver superior performance at varying Mach numbers with trade-offs in manufacturing complexity and operational flexibility.

Key Factors in Nozzle Selection for Engineering Projects

Flow turning nozzles excel in applications requiring precise directional control of exhaust flow to optimize thrust vectoring or reduce flow separation, while convergent-divergent nozzles are chosen for supersonic flow acceleration to achieve higher exit velocities and improved propulsion efficiency. Key factors in nozzle selection include operating pressure ratios, flow Mach number requirements, thermal and structural material limits, and specific project constraints such as size, weight, and manufacturability. Engineers must balance aerodynamic performance, mechanical reliability, and cost implications to select the most suitable nozzle type for propulsion, industrial gas flow, or chemical process applications.

Future Trends and Innovations in Nozzle Technology

Future trends in nozzle technology emphasize enhanced efficiency and precision through advanced materials like ceramics and composites, enabling higher temperature resistance and durability in flow turning nozzles and convergent-divergent nozzles. Innovations include additive manufacturing techniques that allow complex geometries for optimized flow characteristics, reducing turbulence and improving thrust performance. Your aerospace projects can benefit from autonomous control systems integrated into nozzles, which dynamically adjust flow paths for real-time performance optimization and fuel savings.

Flow Turning Nozzle vs Convergent-Divergent Nozzle Infographic

libmatt.com

libmatt.com