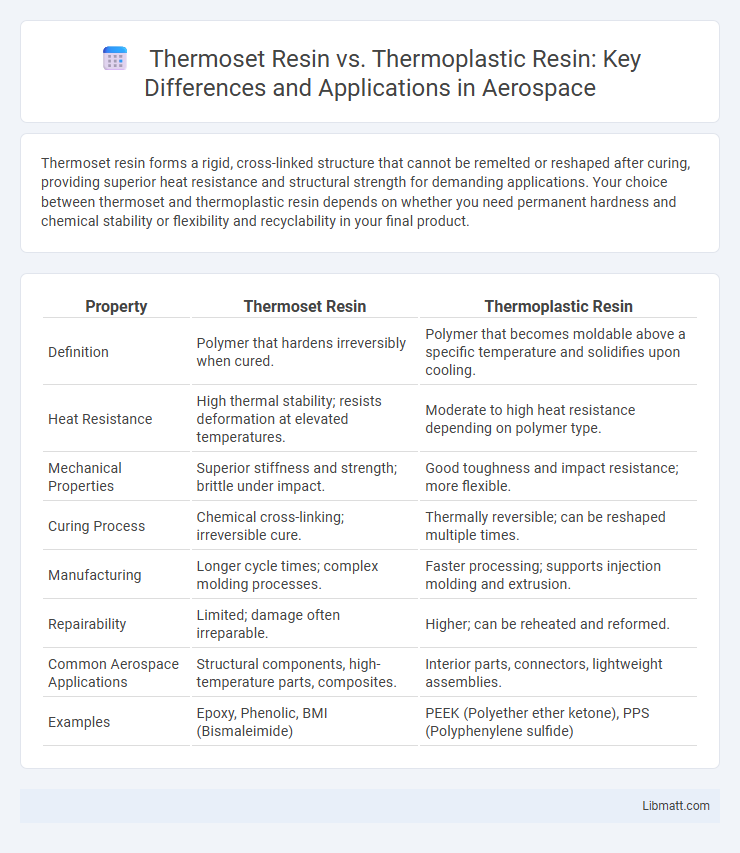

Thermoset resin forms a rigid, cross-linked structure that cannot be remelted or reshaped after curing, providing superior heat resistance and structural strength for demanding applications. Your choice between thermoset and thermoplastic resin depends on whether you need permanent hardness and chemical stability or flexibility and recyclability in your final product.

Table of Comparison

| Property | Thermoset Resin | Thermoplastic Resin |

|---|---|---|

| Definition | Polymer that hardens irreversibly when cured. | Polymer that becomes moldable above a specific temperature and solidifies upon cooling. |

| Heat Resistance | High thermal stability; resists deformation at elevated temperatures. | Moderate to high heat resistance depending on polymer type. |

| Mechanical Properties | Superior stiffness and strength; brittle under impact. | Good toughness and impact resistance; more flexible. |

| Curing Process | Chemical cross-linking; irreversible cure. | Thermally reversible; can be reshaped multiple times. |

| Manufacturing | Longer cycle times; complex molding processes. | Faster processing; supports injection molding and extrusion. |

| Repairability | Limited; damage often irreparable. | Higher; can be reheated and reformed. |

| Common Aerospace Applications | Structural components, high-temperature parts, composites. | Interior parts, connectors, lightweight assemblies. |

| Examples | Epoxy, Phenolic, BMI (Bismaleimide) | PEEK (Polyether ether ketone), PPS (Polyphenylene sulfide) |

Introduction to Thermoset and Thermoplastic Resins

Thermoset resins are polymer materials that undergo a curing process forming irreversible chemical bonds, resulting in a rigid, heat-resistant structure ideal for high-strength applications. Thermoplastic resins consist of polymer chains that can be repeatedly melted and reshaped without altering their chemical composition, offering versatility and recyclability for manufacturing. The fundamental difference lies in their molecular structure and thermal behavior, where thermosets provide durability and thermal stability, while thermoplastics enable reusability and ease of processing.

Chemical Structure Differences

Thermoset resins consist of tightly cross-linked polymer chains forming a three-dimensional network that provides high thermal and chemical resistance but prevents melting upon reheating. Thermoplastic resins feature linear or branched polymer chains without cross-linking, allowing them to soften and remelt multiple times under heat. Understanding these chemical structure differences helps you select the right resin for applications requiring durability versus recyclability.

Manufacturing and Processing Methods

Thermoset resin requires a curing process involving heat or chemical reactions that create a rigid, cross-linked polymer structure, making it ideal for applications needing high thermal resistance and dimensional stability. Thermoplastic resin undergoes melting and solidification during processing, enabling repeated reshaping and recycling through methods such as injection molding, extrusion, or thermoforming. Manufacturing thermosets involves longer cycle times and higher energy input due to irreversible curing, whereas thermoplastics offer faster production rates and versatility in complex part designs.

Mechanical and Physical Properties

Thermoset resins exhibit superior mechanical strength, thermal stability, and chemical resistance due to their cross-linked polymer structure, making them ideal for high-performance applications requiring rigidity and durability. Thermoplastic resins offer greater flexibility, impact resistance, and the ability to be reshaped upon heating, which suits applications needing toughness and recyclability. Your choice between thermoset and thermoplastic resins depends on the balance of mechanical properties and physical behavior required for the specific engineering or manufacturing task.

Heat Resistance and Thermal Stability

Thermoset resins exhibit superior heat resistance and thermal stability due to their cross-linked molecular structure, allowing them to maintain integrity at temperatures often exceeding 200degC. In contrast, thermoplastic resins have lower heat resistance, typically softening between 100degC and 250degC, which limits their use in high-temperature applications. The irreversible curing process of thermoset resins enhances their dimensional stability and resistance to thermal degradation compared to the reversible melting behavior of thermoplastics.

Applications in Various Industries

Thermoset resins are extensively used in aerospace, automotive, and electrical industries due to their high heat resistance, durability, and excellent mechanical properties, making them suitable for structural components, adhesives, and circuit boards. Thermoplastic resins dominate packaging, consumer goods, and medical devices applications because of their recyclability, flexibility, and ease of processing through injection molding and extrusion. The versatility of thermoplastics allows for rapid prototyping and mass production, whereas thermosets provide superior chemical resistance and structural integrity in demanding environments.

Advantages of Thermoset Resins

Thermoset resins offer superior thermal stability and chemical resistance compared to thermoplastic resins, making them ideal for high-temperature applications in the automotive and aerospace industries. Their cross-linked polymer structure provides exceptional mechanical strength and dimensional stability, which enhances durability under stress and environmental exposure. These resins also exhibit excellent electrical insulating properties, widely used in electronic components and circuit boards.

Advantages of Thermoplastic Resins

Thermoplastic resins offer superior flexibility and recyclability compared to thermoset resins, enabling repeated melting and reshaping without chemical degradation. Their impact resistance and toughness enhance durability in automotive and consumer goods applications. Rapid processing cycles and ease of molding make thermoplastics cost-effective and ideal for large-scale manufacturing.

Limitations and Drawbacks

Thermoset resin exhibits limited recyclability due to its irreversible curing process, making material recovery challenging and increasing environmental concerns. Thermoplastic resin, while recyclable, often suffers from lower heat resistance and mechanical strength compared to thermosets, limiting its use in high-temperature or high-stress applications. Your choice between these resins should consider these limitations based on the application's thermal and mechanical demands.

Choosing the Right Resin for Your Application

Thermoset resins offer superior heat resistance and structural integrity, making them ideal for high-temperature and load-bearing applications, while thermoplastic resins provide excellent recyclability and flexibility, suitable for parts requiring repeated shaping and impact resistance. Understanding the mechanical properties, thermal stability, and processing requirements of each resin type is crucial for selecting the right material that meets performance demands and manufacturing constraints. Your choice should balance durability, cost-efficiency, and environmental factors to optimize product longevity and functionality.

Thermoset Resin vs Thermoplastic Resin Infographic

libmatt.com

libmatt.com