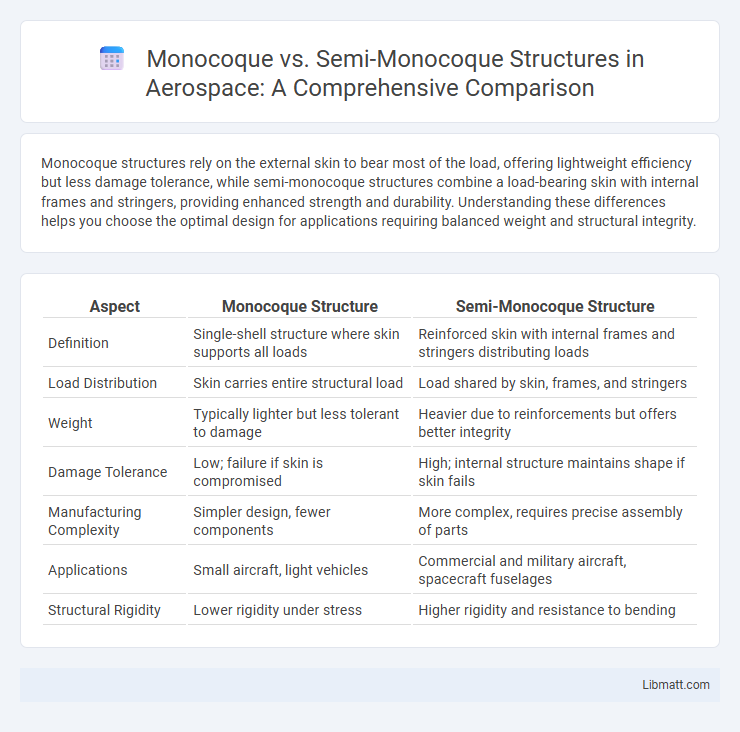

Monocoque structures rely on the external skin to bear most of the load, offering lightweight efficiency but less damage tolerance, while semi-monocoque structures combine a load-bearing skin with internal frames and stringers, providing enhanced strength and durability. Understanding these differences helps you choose the optimal design for applications requiring balanced weight and structural integrity.

Table of Comparison

| Aspect | Monocoque Structure | Semi-Monocoque Structure |

|---|---|---|

| Definition | Single-shell structure where skin supports all loads | Reinforced skin with internal frames and stringers distributing loads |

| Load Distribution | Skin carries entire structural load | Load shared by skin, frames, and stringers |

| Weight | Typically lighter but less tolerant to damage | Heavier due to reinforcements but offers better integrity |

| Damage Tolerance | Low; failure if skin is compromised | High; internal structure maintains shape if skin fails |

| Manufacturing Complexity | Simpler design, fewer components | More complex, requires precise assembly of parts |

| Applications | Small aircraft, light vehicles | Commercial and military aircraft, spacecraft fuselages |

| Structural Rigidity | Lower rigidity under stress | Higher rigidity and resistance to bending |

Introduction to Aircraft Structural Designs

Monocoque structures rely on the external skin to bear most of the loads, providing a lightweight yet strong framework essential for aircraft efficiency. Semi-monocoque designs incorporate an internal framework of ribs and stringers, distributing stress across both the skin and underlying structure for enhanced durability and damage tolerance. These structural approaches form the foundation of modern aircraft, balancing weight reduction with the need for safety and performance.

Defining Monocoque Structure

Monocoque structure is an engineering design where the external skin supports most of the load, eliminating the need for an internal frame or skeleton. This design relies on the strength and rigidity of the outer shell, commonly used in aircraft fuselages and automotive bodies for weight reduction and aerodynamic efficiency. Unlike semi-monocoque structures, monocoque provides structural integrity primarily through its skin, making it lighter but typically less resistant to localized damage.

Understanding Semi-Monocoque Structure

Semi-monocoque structure combines a load-bearing skin with an internal framework of stringers and bulkheads, optimizing strength-to-weight ratio in aircraft design. Unlike pure monocoque, which relies solely on the outer shell for structural integrity, semi-monocoque distributes stress across multiple components, enhancing durability and damage resistance. This configuration is widely used in modern airplanes due to its efficient balance of rigidity, weight savings, and ease of repair.

Key Differences Between Monocoque and Semi-Monocoque

Monocoque structures rely on the external skin to bear all or most of the load, creating a lightweight but less damage-tolerant design often used in automotive and aerospace applications. Semi-monocoque structures combine a load-bearing skin with an internal framework of stringers and bulkheads to enhance strength, durability, and resistance to localized damage. The key differences lie in load distribution and structural complexity, with semi-monocoque offering greater redundancy and impact resistance compared to the simpler monocoque design.

Structural Strength and Load Distribution

Monocoque structures rely on the external skin to bear most of the structural stresses, offering high strength-to-weight ratios by distributing loads uniformly across the surface. Semi-monocoque designs incorporate internal framework such as frames and stringers alongside the skin, enhancing load distribution and improving resistance to localized stress and damage. This hybrid approach in semi-monocoque structures balances rigidity and flexibility, resulting in increased structural durability under dynamic and concentrated loads compared to pure monocoque designs.

Material Choices and Construction Techniques

Monocoque structures rely on a single shell made from materials like aluminum, carbon fiber, or fiberglass, providing a lightweight yet strong framework by distributing stress across the external skin. Semi-monocoque designs combine a skin-supported framework of frames, stringers, and bulkheads, often using aluminum alloys or composites for enhanced durability and ease of repair. Your choice between these construction techniques impacts factors such as weight, strength, and maintenance complexity, with monocoque favoring simplicity and semi-monocoque offering improved damage tolerance and structural redundancy.

Weight Considerations and Performance

Monocoque structures offer superior weight savings by integrating the skin and frame into a single load-bearing shell, enhancing overall performance through increased rigidity and reduced material usage. Semi-monocoque designs add internal reinforcements like stringers and frames, providing greater durability and damage tolerance at a slight weight penalty, which can improve structural longevity in demanding conditions. Your choice between these structures should balance weight efficiency with performance requirements, especially for applications where minimizing mass directly impacts fuel economy and agility.

Maintenance and Repair Challenges

Monocoque structures offer the advantage of reduced weight but can present significant maintenance and repair challenges due to their integral load-bearing design, which requires specialized techniques and materials for damage assessment and restoration. Semi-monocoque structures distribute loads across a framework of frames and stringers covered by a stressed skin, allowing easier inspection, localized repairs, and replacement of damaged sections without compromising overall structural integrity. Your choice between these designs impacts repair costs and downtime, with semi-monocoque typically providing more straightforward maintenance workflows in aviation and automotive applications.

Common Applications in Aviation and Automotive Industries

Monocoque structures are widely used in automotive racing cars and light aircraft due to their lightweight and high strength, providing improved fuel efficiency and performance. Semi-monocoque structures dominate commercial aviation and modern vehicle design, combining a load-bearing skin with internal supports to enhance durability and impact resistance. Your choice between these structures influences weight, structural integrity, and maintenance requirements in both aviation and automotive applications.

Choosing the Right Structure: Factors to Consider

Choosing between monocoque and semi-monocoque structures depends on factors like weight efficiency, load distribution, and manufacturing complexity. Monocoque structures offer lightweight design ideal for applications requiring minimal weight, while semi-monocoque provides enhanced strength through load-sharing components, suitable for high-stress environments. Your decision should weigh the balance between structural integrity, maintenance requirements, and cost-effectiveness to ensure optimal performance.

Monocoque vs Semi-monocoque Structure Infographic

libmatt.com

libmatt.com